Full-automatic X-ray detecting and sorting system for shells

A sorting system and X-ray technology, applied in the application field of X-ray detection technology, can solve the problems of inability to guarantee the quality of seashells and unreasonable automatic material distribution, so as to solve the problem of food quality control, save costs, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

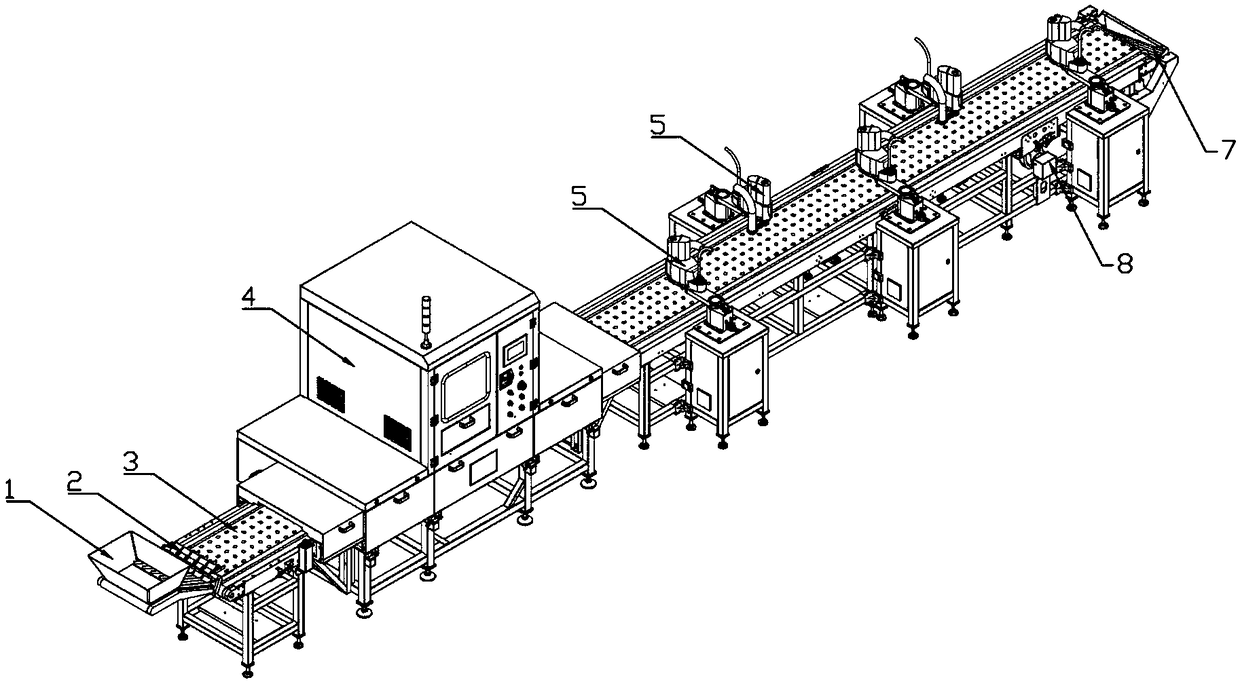

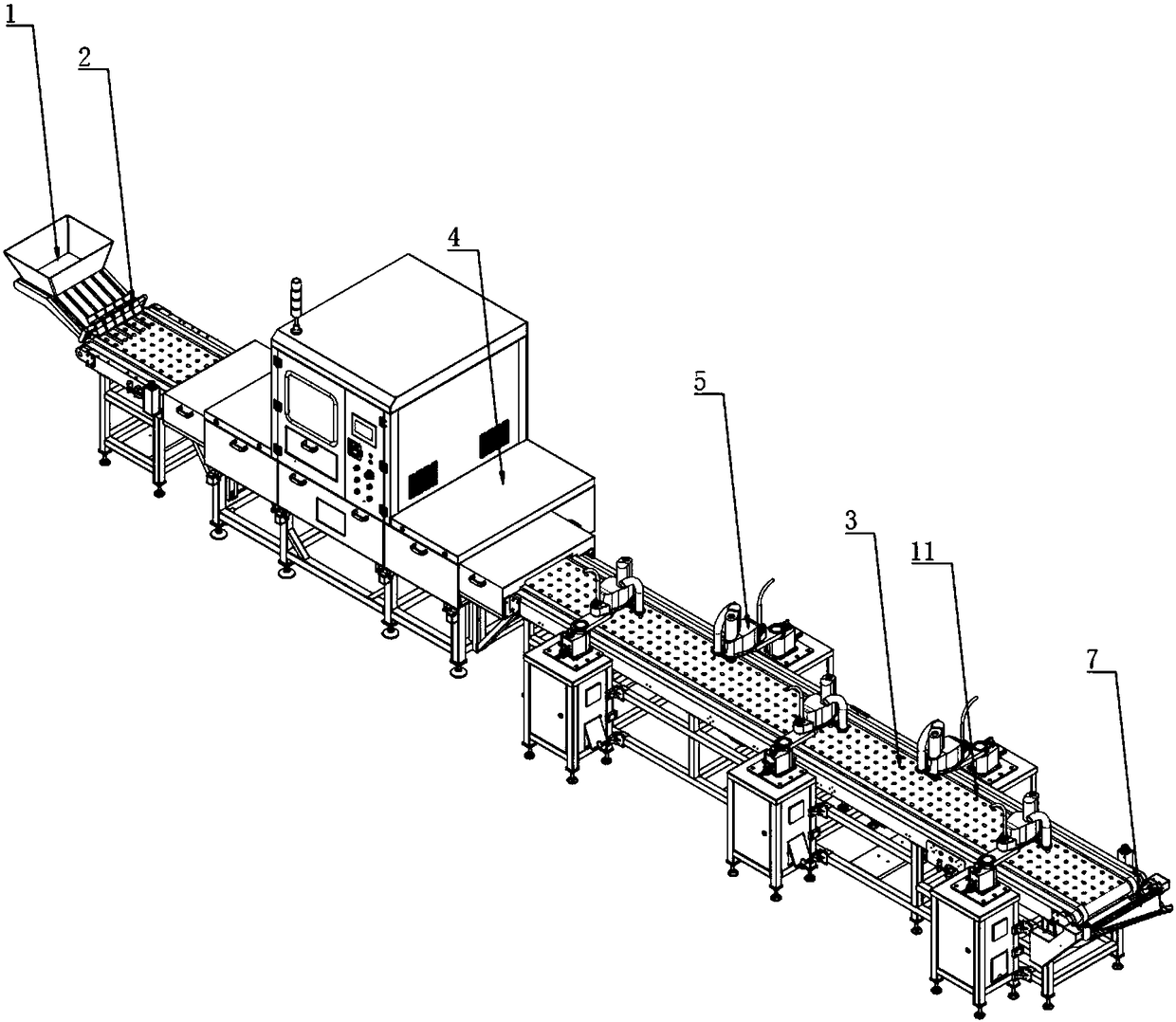

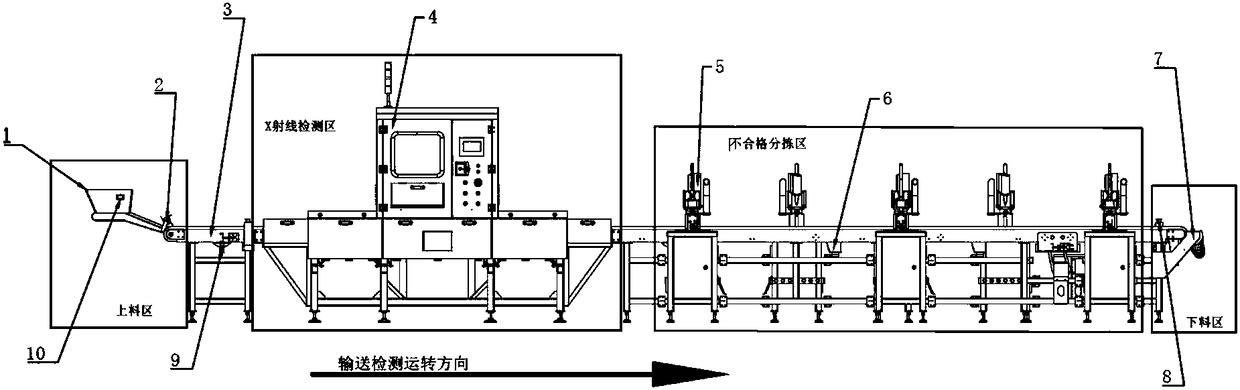

[0018] As shown in the figure, a fully automatic X-ray detection and sorting system applied to shells includes a feeding hopper 1, an intermittent feeding and sorting mechanism 2, a transmission conveyor 3, and an X-ray seashell food detector 4. The picking manipulator 5 and the cleaning and sorting mechanism 7, the feeding hopper 1 is connected with the transmission conveyor 3 through the intermittent feeding and distributing mechanism 2, and the transmission conveyor 3 passes through the X-ray seashell food inspection machine 4 in turn, The sorting manipulator 5 arrives at the cleaning and sorting mechanism 7, and the X-ray seashell food detection machine 4 includes an X-ray source 12, an alignment pair 13, a line array receiver 14 and a detection position sensor 16, and the X-ray source 12. The center alignment pair 13 and the detection position sensor 16 are located above the conveying conveyor 3, the line array receiver 14 is located below the conveying conveyor 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com