Machine tool

A machine tool and bed technology, applied in lathes, conveyors, metal processing machinery parts, etc., can solve the problems of workpiece scratches and large changes in manufacturing tolerances, and achieve the effect of reducing the installation area and reducing the risk of debris accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

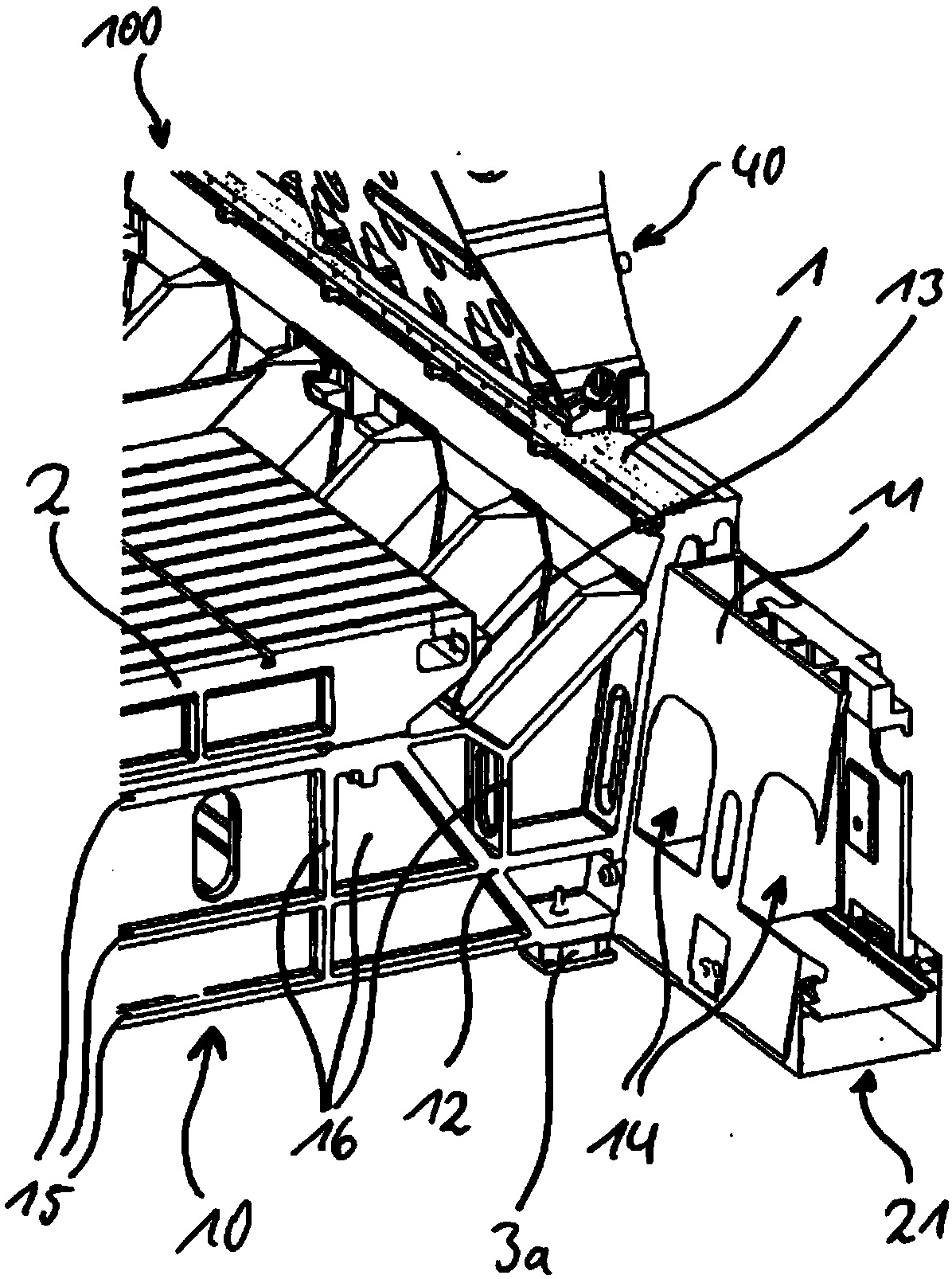

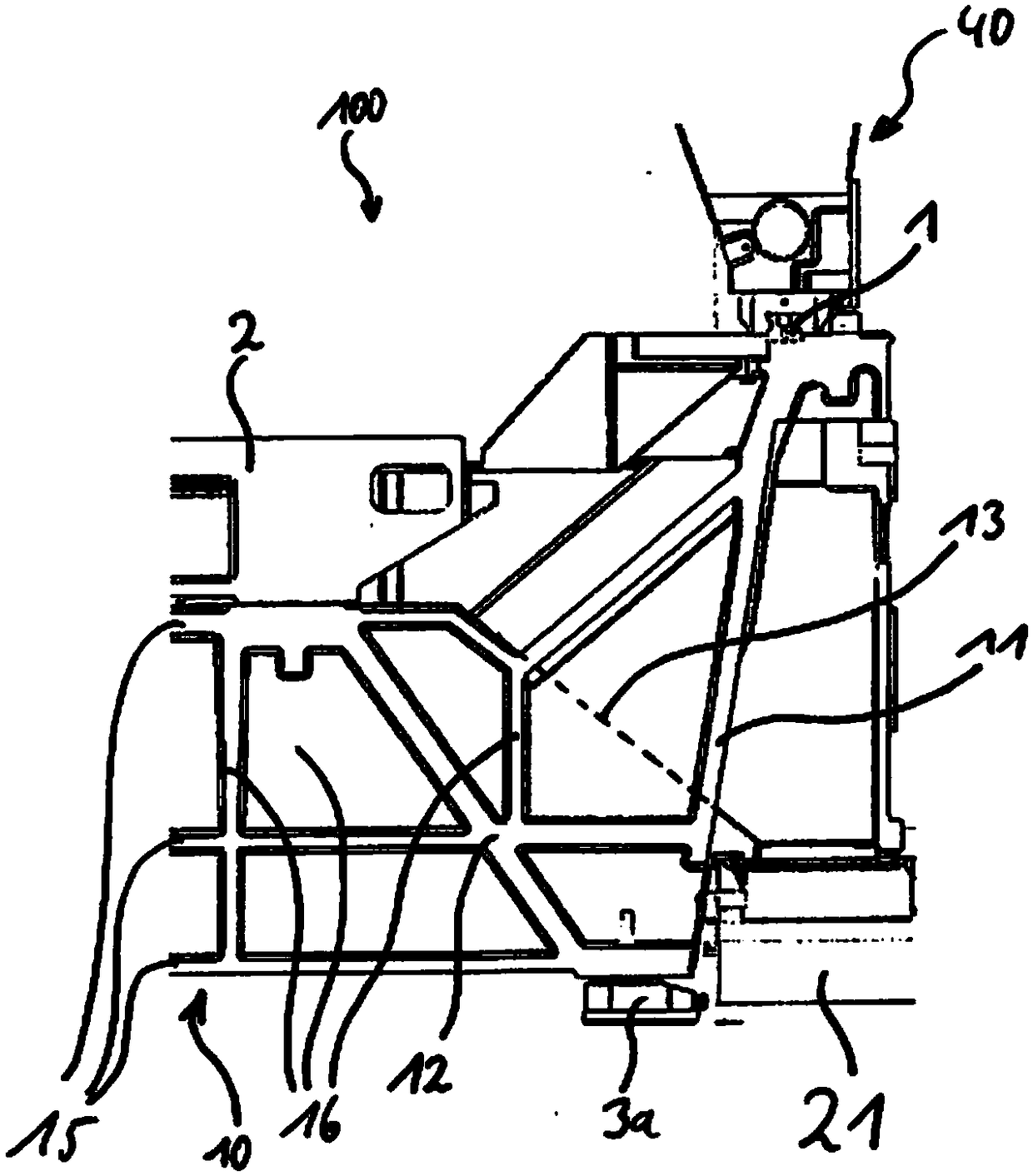

[0039] The examples and exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The same or similar elements in the drawings may be represented by the same reference numerals.

[0040] However, it is worth noting that the present invention is not limited or limited to the exemplary embodiments described below and their design features, but also includes changes to the exemplary embodiments, especially changes to the described examples The features of or the combination of single or several features of the described examples are all within the protection scope of the independent claims.

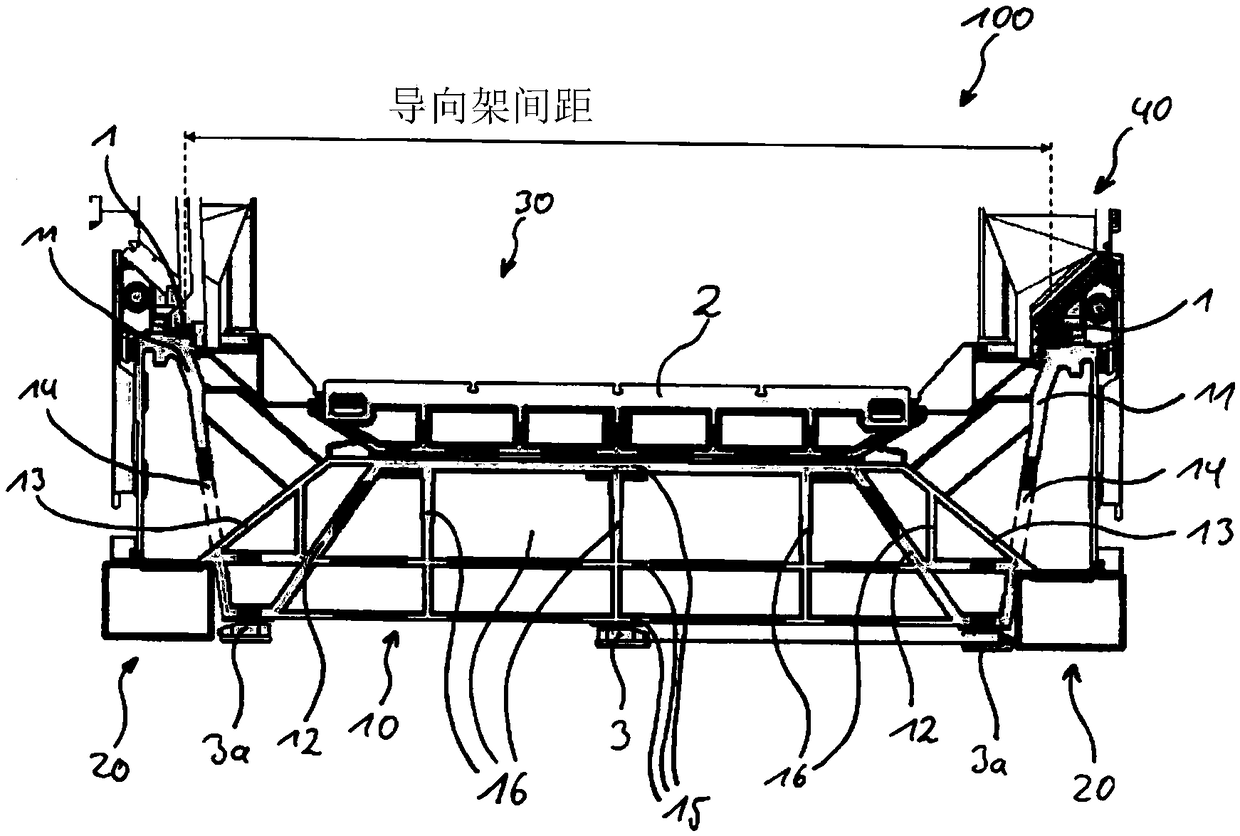

[0041] figure 1 Schematically shows an embodiment of the machine tool 100 according to the present invention. The machine tool 100 includes a first main rib 11, a second main rib 12, and a guide rib 13. The first main rib 11, the second main rib 12, and the guide rib 13 serve as a supporting structure. In the bed 10 of the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com