Electrostatic suction cup refurbishing tooling and refurbishing method thereof

An electrostatic chuck and tooling technology, which is used in manufacturing tools, grinding drives, metal processing equipment, etc., can solve problems such as process difficulties and electrostatic chuck damage, and achieves the ability to eliminate force differences, uniform force, and not easy to accidentally scratch. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

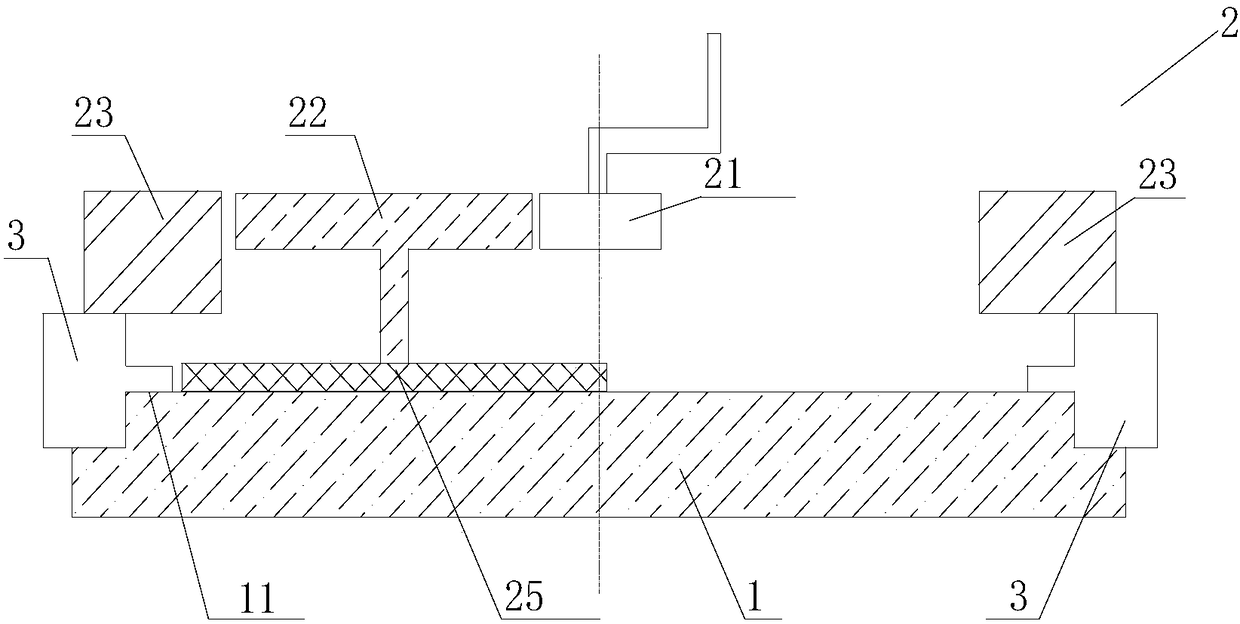

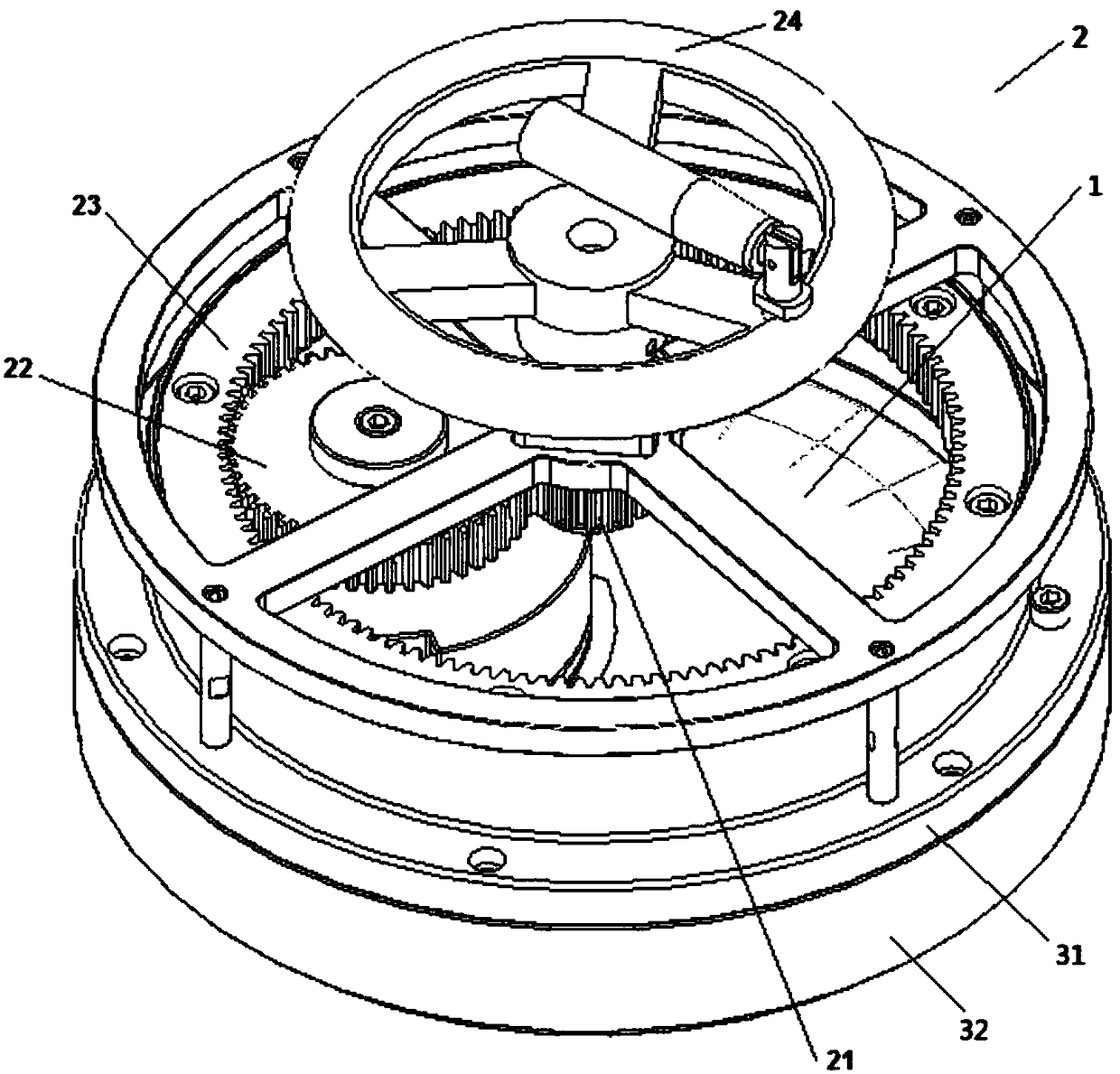

[0027] Such as figure 1 As shown, the electrostatic chuck 1 is a disc with a convex cross section. Made of plastic POM (a kind of engineering plastic), it has the characteristics of high hardness, high rigidity and high wear resistance. The raised convex surface in the middle is used to fix the wafer to be etched, and the polymer generated during etching accumulates on this surface. A slightly lower portion around the circle is provided with threaded holes for fixing the support seat 3 in this embodiment. On the outer edge of the convex surface of the electrostatic chuck 1, there is a ring-shaped sealing protection tape 11 with a ring width of a. The sealing protection tape 11 plays a role of sealing when etching the wafer, and prevents the halogen-based plasma gas used in etching from escaping. Therefore, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com