Novel weather-proof plastic surface hot stamping method

A weather-resistant, plastic technology, applied in the field of plastic processing, can solve the problems of easy breakage, poor weather resistance of plastic hot stamping, etc., and achieve the effect of improving weather resistance, process environmental protection, and keeping pictures and texts intact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

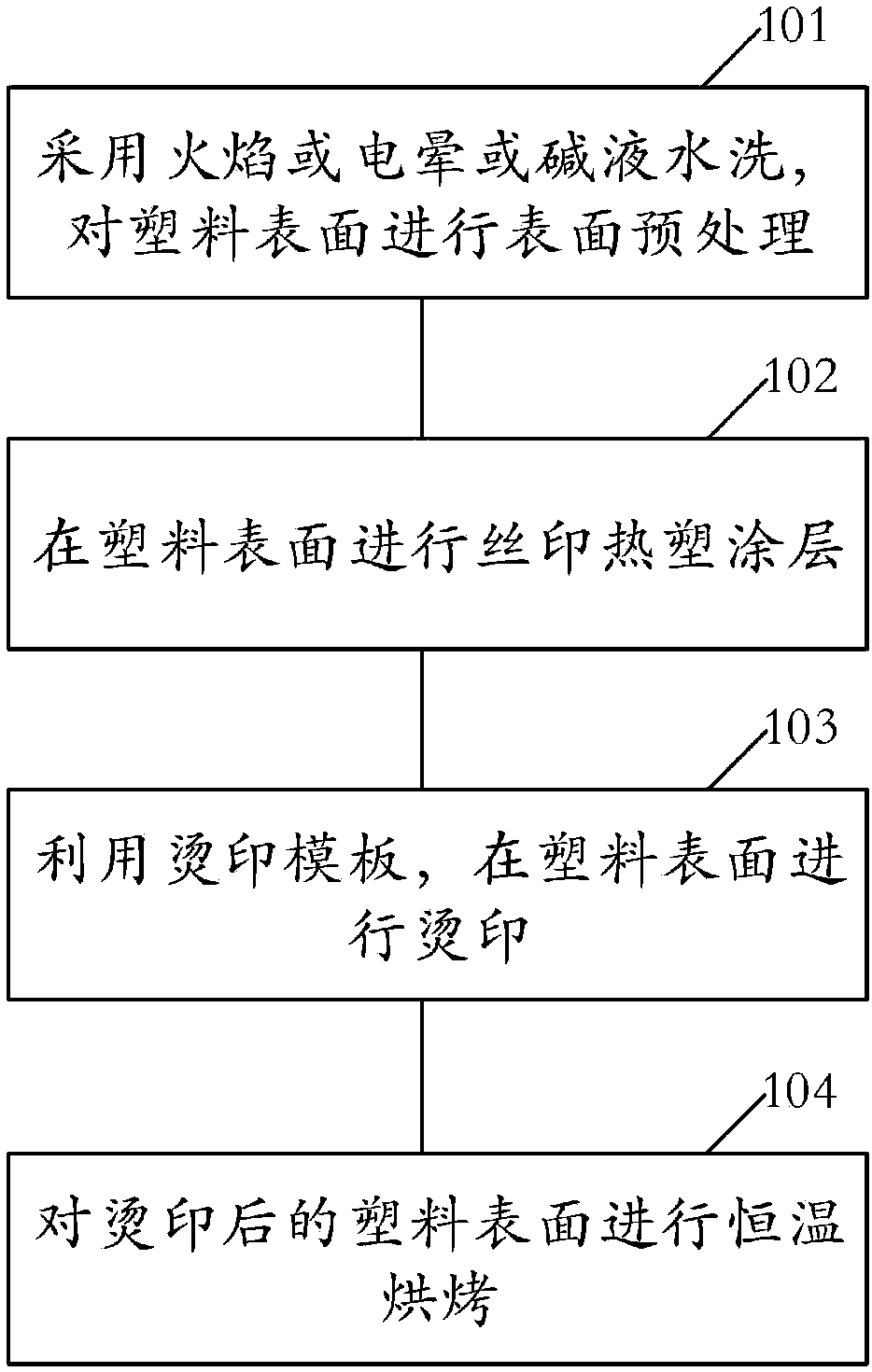

[0014] Such as figure 1 Shown, a kind of novel weather-resistant plastic surface hot stamping method provided by the present invention comprises:

[0015] Step 101, performing surface pretreatment on the plastic surface by washing with flame, corona or lye;

[0016] Among them, surface pretreatment can improve the adhesion and water resistance of later graphics and text.

[0017] Step 102, performing silk-screen thermoplastic coating on the plastic surface;

[0018] Step 103, using a hot stamping template to perform hot stamping on the plastic surface;

[0019] Step 104, performing constant temperature baking on the hot stamped plastic surface.

[0020] Wherein, step 102 may specifically include:

[0021] Step 102-1, printing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com