Wine making decoction device

A technology of decocting and charging medicine, which is applied in the field of brewing, can solve the problems of low degree of mechanization, and achieve the effect of uniform mixing of medicinal properties, simple structure and timely consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

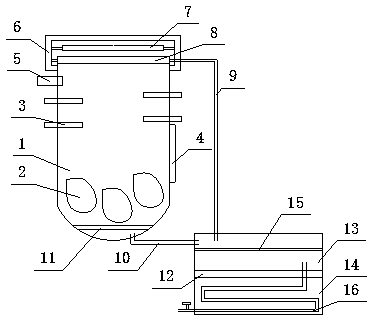

[0010] Embodiment 1: as figure 1 As shown, the present invention includes a decoction tank 1, and also includes a mixing and cooling tank. A plurality of medicine bags 2 made of gauze are arranged in the decoction tank 1, and a movable placement plate is provided on the inner wall of the decoction tank 1. 3. The control end of the placement plate 3 is located on the outer wall of the decoction tank 1, one side of the decoction tank 1 is a transparent observation window 4, the upper part of the decoction tank 1 is provided with a water inlet 5, and the top is provided with a Condensation recovery device, the condensation recovery device includes a condensation shell 6, a condensation pipe 7 and a liquid collection tank 8, the condensation shell 6 is covered on the top of the decoction tank 1, the condensation pipe 7 and the liquid collection tank 8 are annular, and are located in the condensation The inner wall of the shell 6, the condensation pipe 7 is located directly above t...

Embodiment 2

[0011] Embodiment 2: Same as the above embodiment 1, wherein the above-mentioned decoction tank 1 is provided with a timer and a temperature display.

[0012] The decoction process of the present invention:

[0013] First put the same type of Chinese medicinal materials into the same medicine bag 2, then put all the medicine bags 2 into the decoction tank 1, add water from the water inlet 5 to soak, after soaking, put the Chinese medicine that needs to be boiled first The drug-filled bag 2 is placed in the decoction tank 1, and the remaining drug-filled bags 2 are placed through the internal placement plate 3, and the condensation recovery device is covered to start boiling. The control end of the placing plate 3 on the outer wall of the boiling tank 1 controls the tilting of the placing plate 3, pours the medicine bag 2 into the boiling tank 1, and continues boiling. Put it into the mixing chamber 13, then add water from the water inlet 5, carry out the second boiling and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com