F-theta lens for laser processing

A laser processing and lens technology, applied in the optical field, can solve problems such as large distortion, small field of view, and large telecentricity, and achieve the effects of reducing measurement error, small distortion, and suppression of laser spot deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

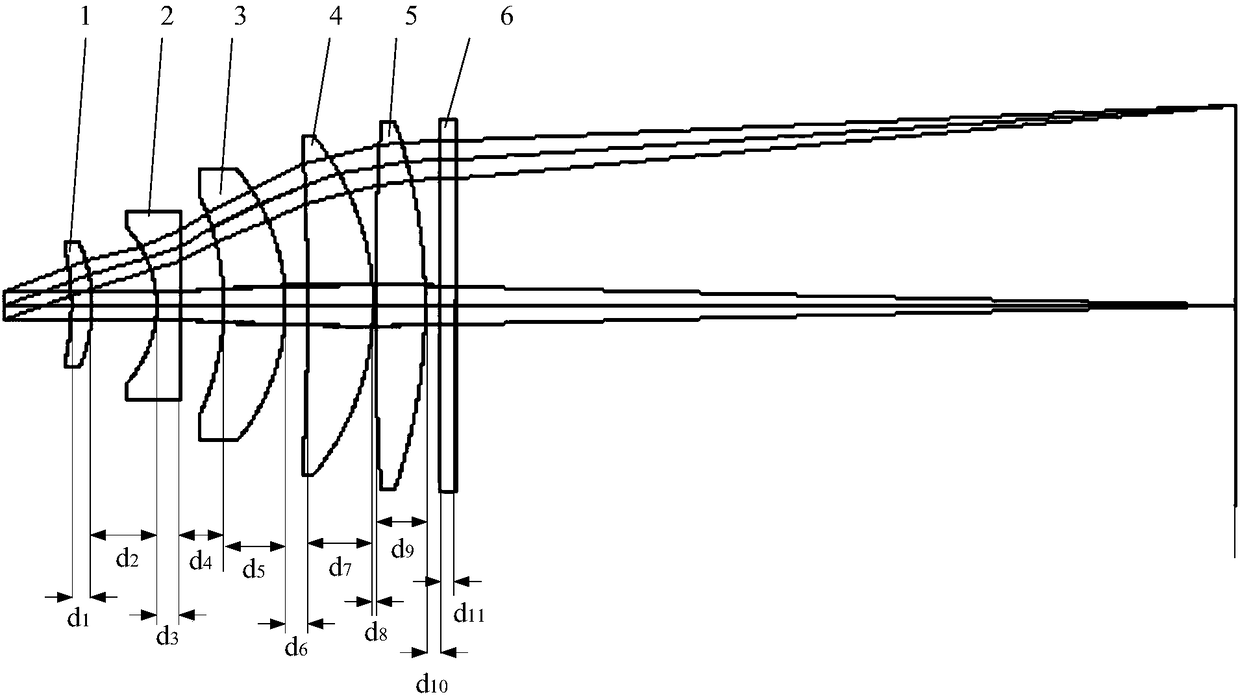

[0056] see Figure 4 , Figure 4 Schematic diagram of the structure of the F-theta lens provided for the second embodiment of the present invention, the F-theta lens includes: a first lens 1, a second lens 2, a third lens 3, a fourth lens 4, a fifth lens 5 and Protective window 6; Wherein the first lens 1 has positive refraction power; The second lens 2 has negative refraction power; The third lens 3 has positive refraction power; The fourth lens 4 has positive refraction power; The fifth lens 5 has positive refraction power degree; the protective window 6 is used to prevent the internal optical elements of the lens group from being affected by external dust and stray light, so the protective window 6 is a plane lens and does not have positive or negative refractive power.

[0057] Preferably, the focal length of each of the lenses and the total focal length of the F-theta lens satisfy the following relationship:

[0058] f1 / f=1.26

[0059] f2 / f=-0.435

[0060] f3 / f=2.25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com