Bi-telecentric camera lens based on machine vision

A bi-telecentric lens and machine vision technology, applied in the direction of instruments, optical components, optics, etc., can solve the problem that the performance of the lens is easily affected by environmental factors such as temperature, it is difficult to ensure the consistency of measurement conditions, and the measurement range of the bi-telecentric lens Limited problems, to achieve the effect of ensuring the consistency of measurement conditions, low distortion, and low telecentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

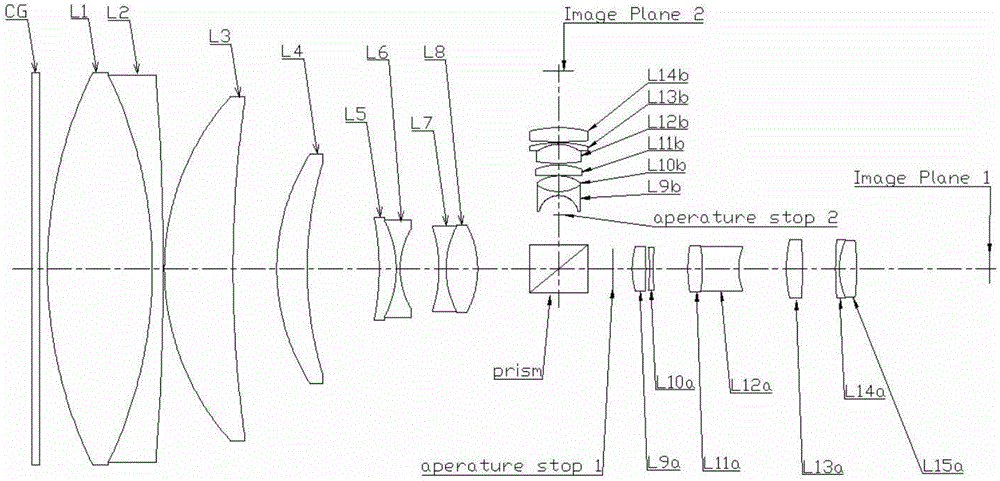

[0066] see figure 1 , is a structural diagram of the dual-magnification bi-telecentric lens of the present invention, and the present invention will be described in detail below with the help of drawings and charts. This bi-telecentric lens based on machine vision is characterized by setting protective glass, lens front group, transflective device, diaphragm, first lens rear group for low magnification measurement and high The second lens rear group for magnification measurement; the lens front group includes eight lenses: the first lens L1, the second lens L2, the third lens L3, the fourth lens L4, and the fifth lens L5 are arranged in sequence from left to right , the sixth lens L6, the seventh lens L7, and the eighth lens L8; wherein, the first lens L1 and the second lens L2 form a double cement and the cemented surface is bent toward the object plane, and the third lens L3 and the fourth lens L4 are both curved Moon-shaped and bent towards the diaphragm, the fifth lens L5...

Embodiment 2

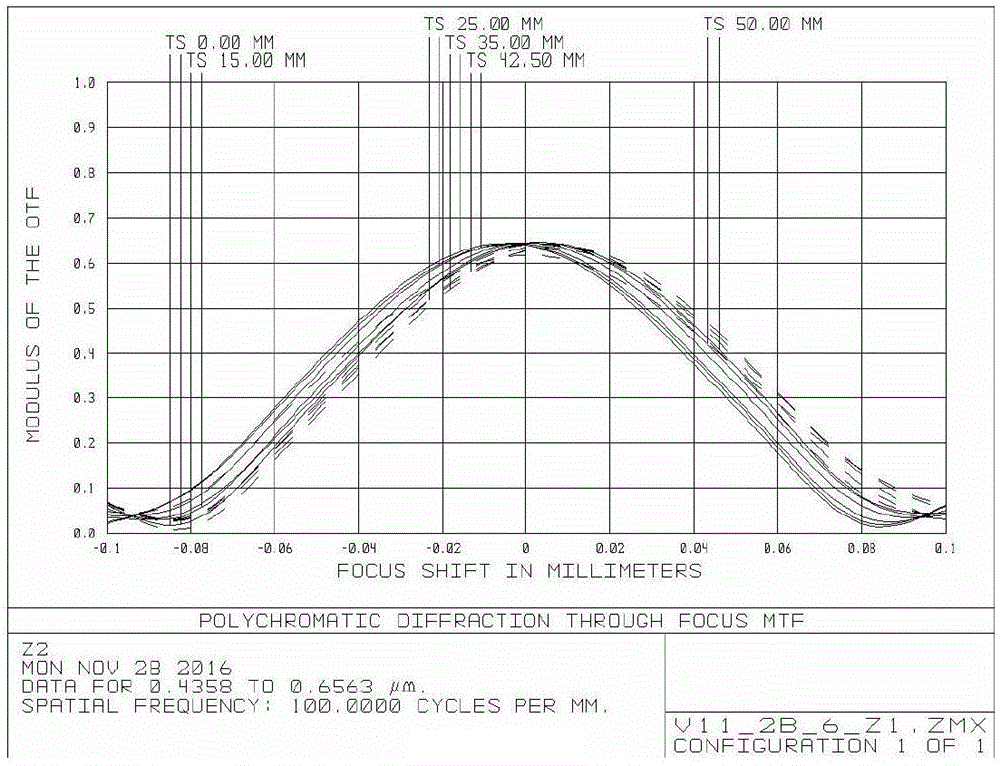

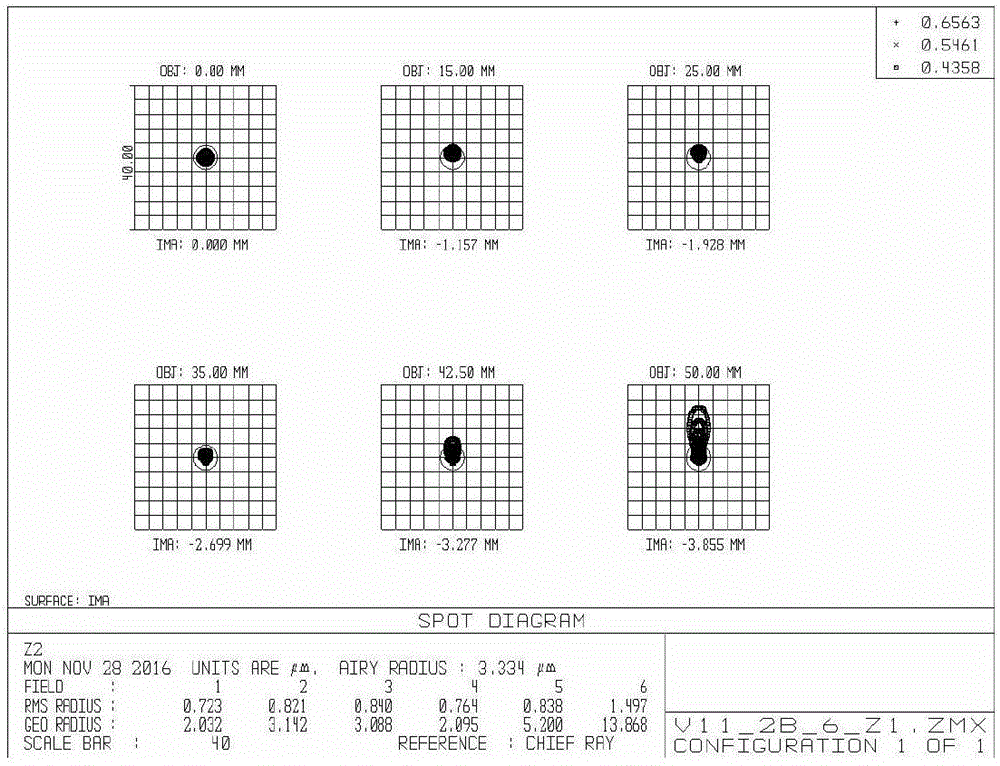

[0101] The preferred parameter table of Embodiment 2 is as follows: Table 7 to Table 9 are high magnification telecentric optical path parameter values, and Table 10 to Table 12 are low magnification telecentric optical path parameter values. Figure 16-Figure 27 It is an illustration of the lens analysis and temperature characteristics of the second embodiment. It can be seen from the graph that, under the condition of ensuring low telecentricity, the lens meets the requirements in terms of resolution, distortion, temperature characteristics and the like.

[0102] Table Seven

[0103] field FOV (degree) CRA (degree) 0.1 0.0006 0.007 0.2 0.0009 0.011 0.3 0.0016 0.016 0.4 0.0024 0.022 0.5 0.0033 0.035 0.6 0.0039 0.041 0.7 0.0045 0.045 0.8 0.0050 0.035 0.9 0.0052 0.023 1 0.0055 0.017

[0104] table eight

[0105] G12 / f4 G56 / G78 G9b / f11b G12b / G14b 0.55 -0.75 -1.55 2.52

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com