Automatic feeding line for duck fodder particles and working method of automatic feeding line

A technology of automatic feeding and duck feed, which is applied in the field of poultry breeding, can solve the problems of ducks missing the best feeding time, the accuracy of manual feeding is not high, and the economic burden of farmers, so as to save costs, reduce labor and fast delivery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

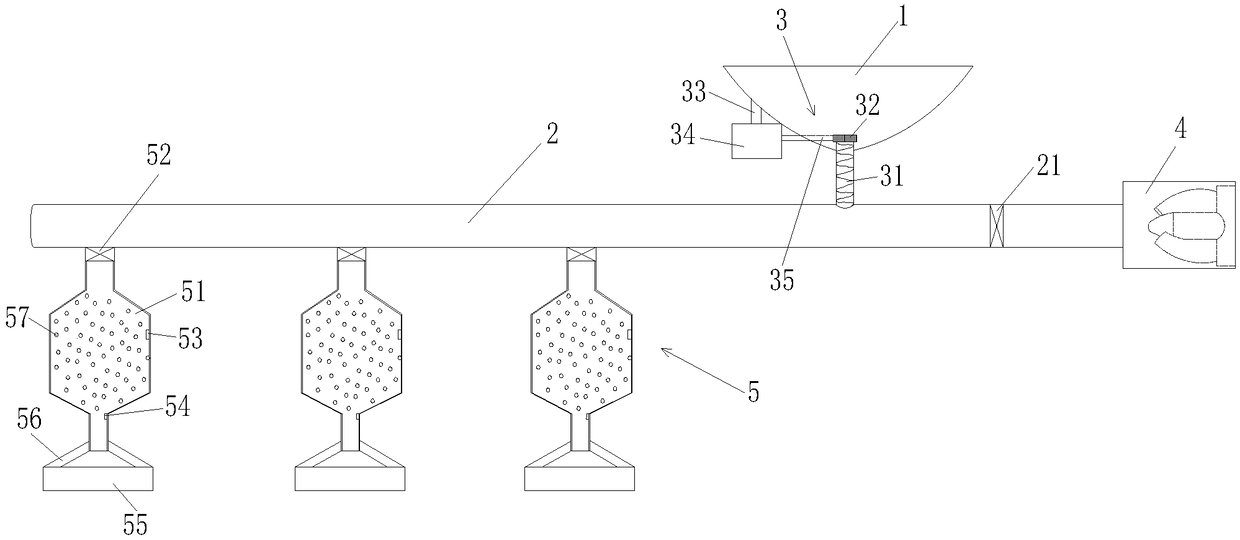

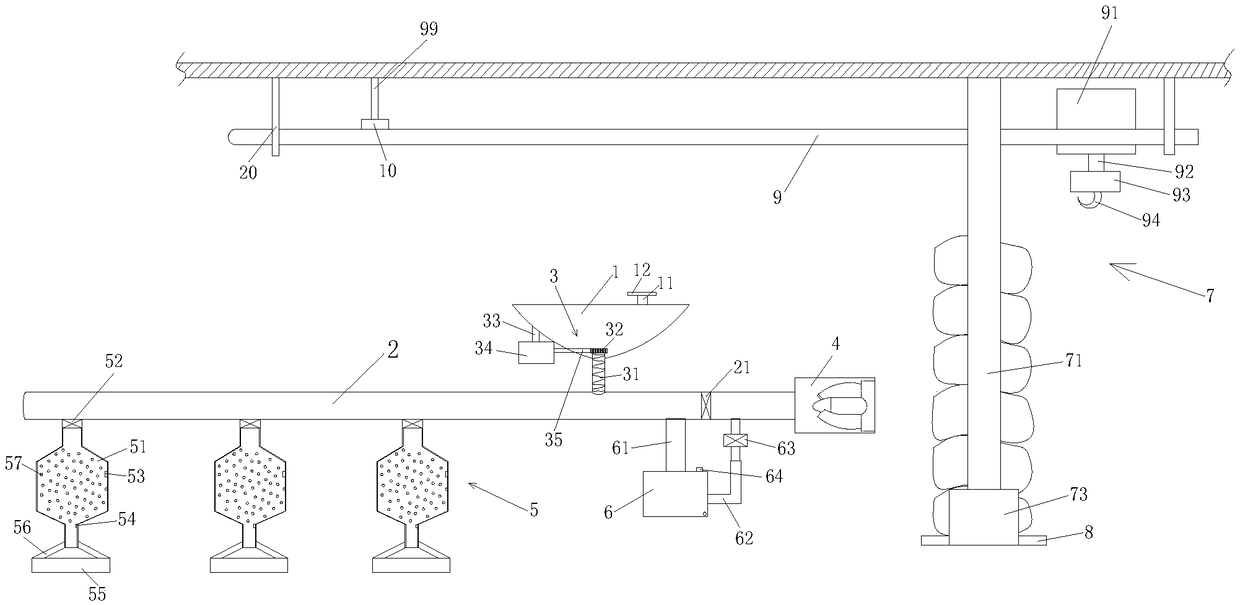

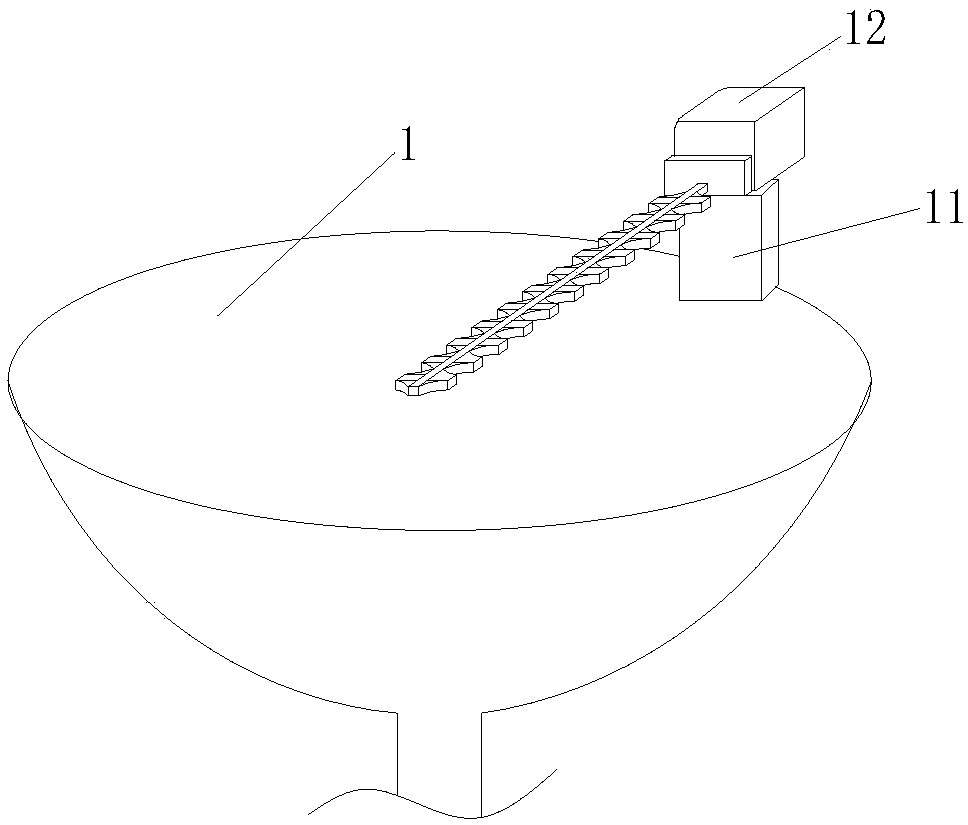

[0026] see Figure 1 to Figure 3 As shown, the present invention provides an embodiment: an automatic feeding line for granular duck feed, comprising a material cavity 1, the upper surface of the material cavity 1 is opened to form a first feeding port, and the lower surface of the material cavity 1 is opened to form a The first discharge port; the discharge port of the material chamber 1 is connected to a conveying pipeline 2, and the conveying pipeline 2 is located below the material chamber 1; the material chamber 1 is provided with a feeding assembly 3; One end of the conveying pipeline 2 is provided with a vortex generator 4, and the conveying pipeline 2 is provided with a first solenoid valve 21, and the first solenoid valve 2 is located between the material chamber 1 and the vortex generator 4; the conveying pipeline 2, a plurality of material holding devices 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com