Atomization disinfection device

A technology of disinfection device and warm air device, which is applied in the field of sterilization and disinfection, can solve the problems of ineffective disinfection of instruments and equipment, and secondary pollution of reagents on the job site, so as to avoid secondary pollution and harm, and improve stability , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

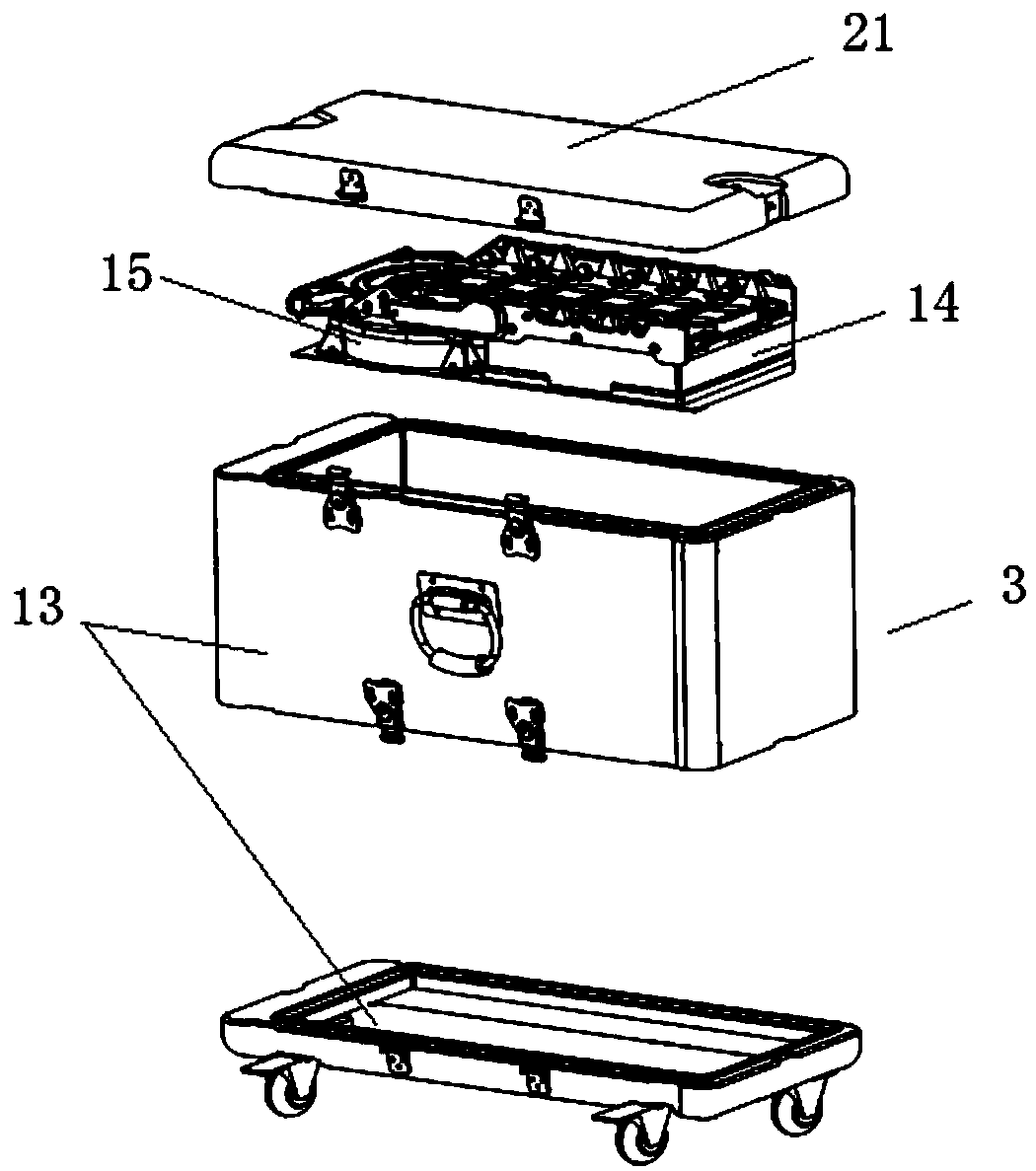

[0030] An atomization disinfection device, including an atomization module 2 for converting a liquid reagent into an atomized and / or vaporized state and spraying it, and a residual reagent treatment module 3 for filtering residual reagents in a disinfection space, the atomization module 2 Both the residual reagent processing module 3 and the control module 1 are electrically connected, and the control module 1 controls the opening / closing of the atomization module 2 and the residual reagent processing module 3 .

[0031] Through the atomization disinfection device with the above structure, when in use, the staff can add liquid reagents into the atomization module 2, and start the atomization module 2 through the control module 1, and the atomization module 2 can dissipate the liquid reagent The reagent is converted into an atomized and / or vaporized state, so that the reagent in the atomized and / or vaporized state can effectively sterilize the surface, complex chambers and / or ga...

Embodiment 2

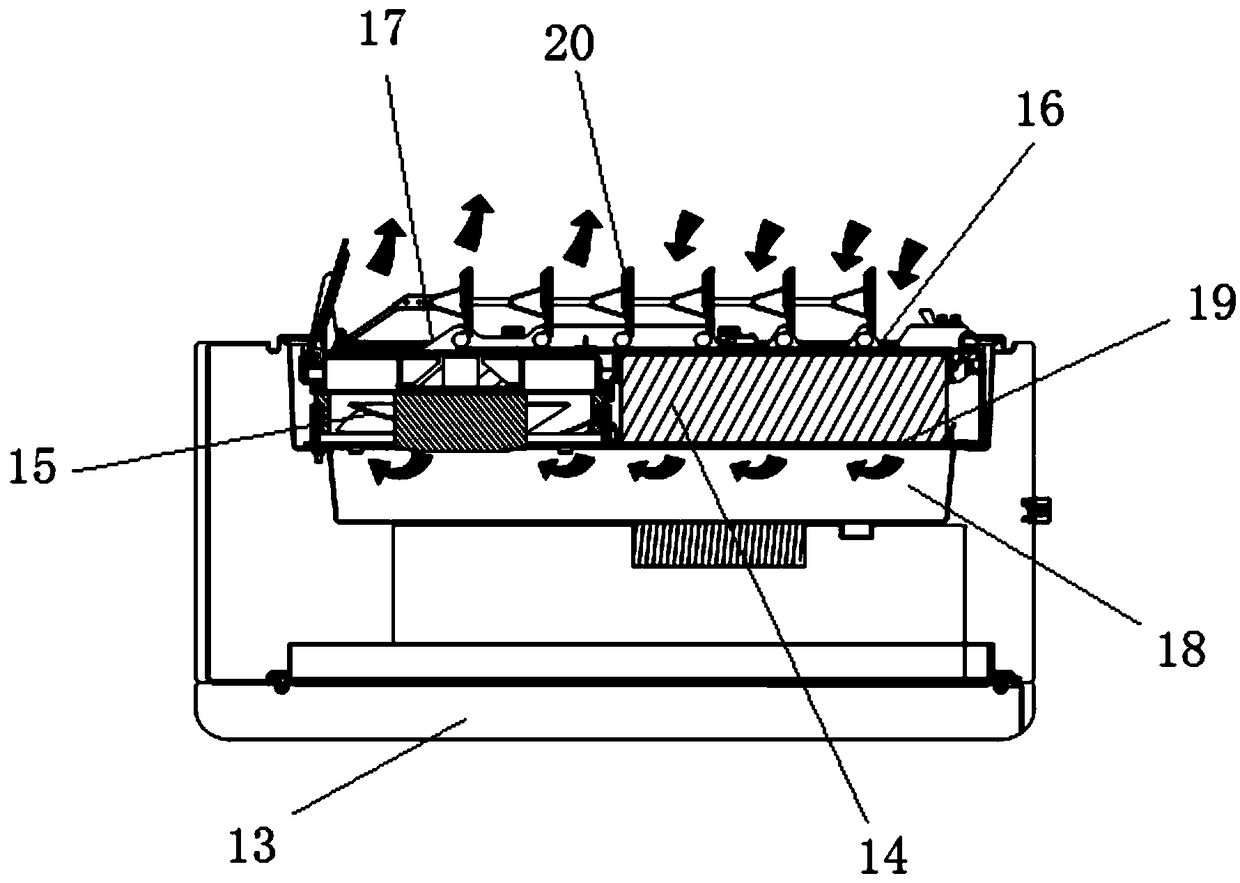

[0043] As a further optimization of the above embodiment, the above residual reagent processing module 3 includes a box body 13, an opening is provided on one side of the box body 13, and a filter assembly 14 is arranged inside the box body 13;

[0044] Wherein, filter assembly 14 is provided with fan 15, air inlet 16 and air outlet 17, and fan 15 is electrically connected with control module 1, can control the opening / closing of fan 15 through control module 1; Air inlet 16 and air outlet 17 all face One side of the opening on the box body 13 is set, the air outlet end of the fan 15 is set towards the air outlet 17, the distance between the bottom of the filter assembly 14 and the bottom of the inside of the box body 13 forms an air duct 18, and the air inlet 16 passes through the air duct. The duct 18 communicates with the air inlet end of the fan 15, and a filter screen 19 for filtering residual reagents in the air is arranged in the air duct 18.

[0045] The working mode o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com