Thermoforming line and production method for variable strength parts

A production method and variable strength technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor product processing flexibility, fixed delayed cooling area, and can not be set arbitrarily, so as to reduce tissue stress and reduce cooling Time, the effect of increasing elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

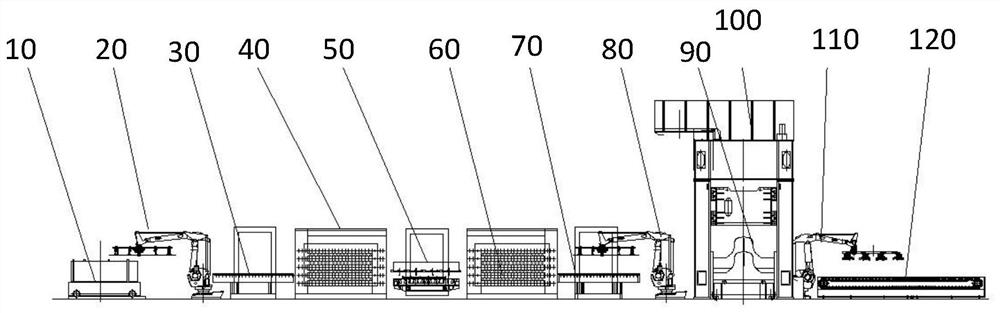

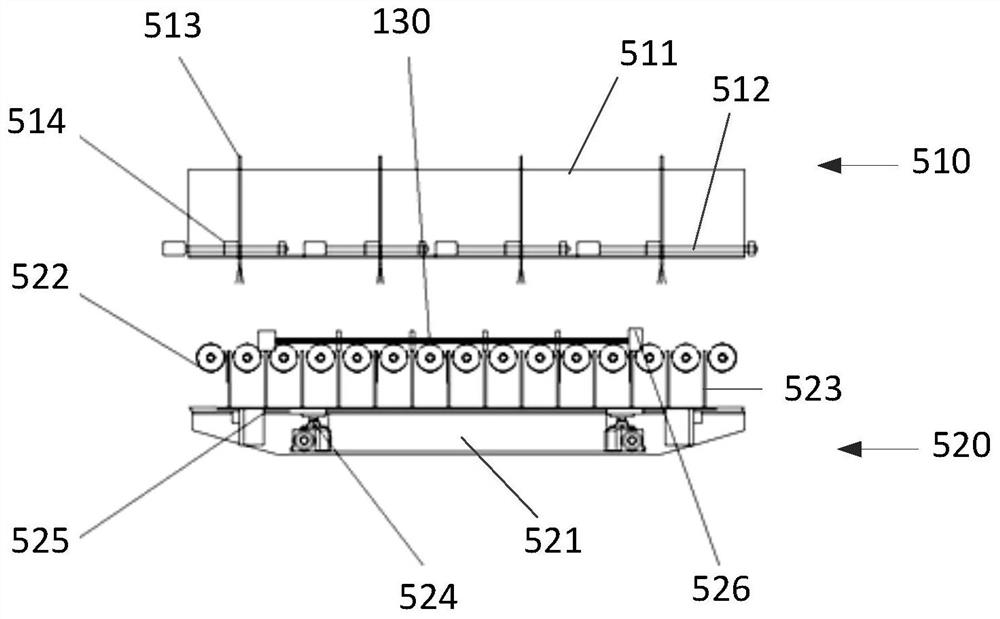

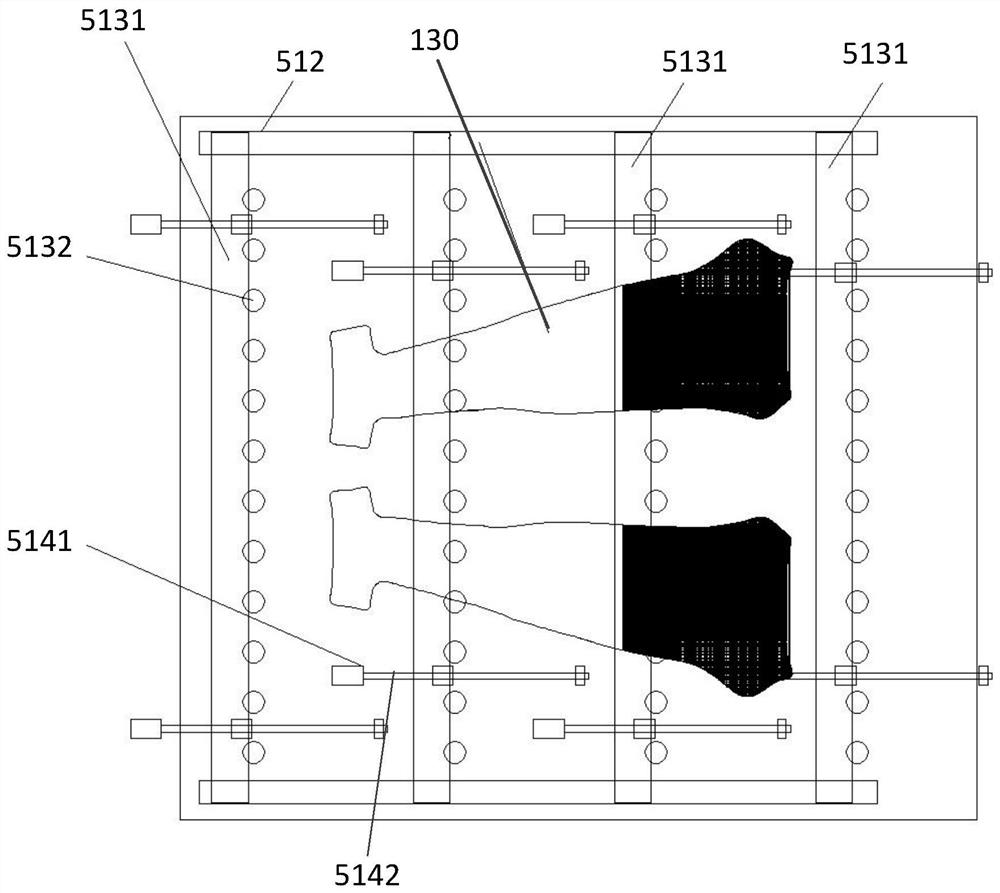

[0033] like figure 1 As shown, the present invention provides a thermoforming production line for variable strength parts, which is used for producing variable strength thermoformed parts. The production line specifically includes: a destacking device, a feeding device, a first heating furnace 40, an air blowing cooling device 50, a second heating furnace 60, a discharging device, a press 100 and a feeding device. Wherein, the destacking device adopts a destacking trolley 10, the feeding device include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com