Mobile phone middle frame machining technology

A mobile phone middle frame and processing technology technology, applied in the field of mobile phones, can solve the problem that the distance between the face screen supporting step surface 15 and the middle plate 20 cannot be guaranteed within the dimensional tolerance range, the large dimensional error of the face screen supporting step face 15, and easy deformation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

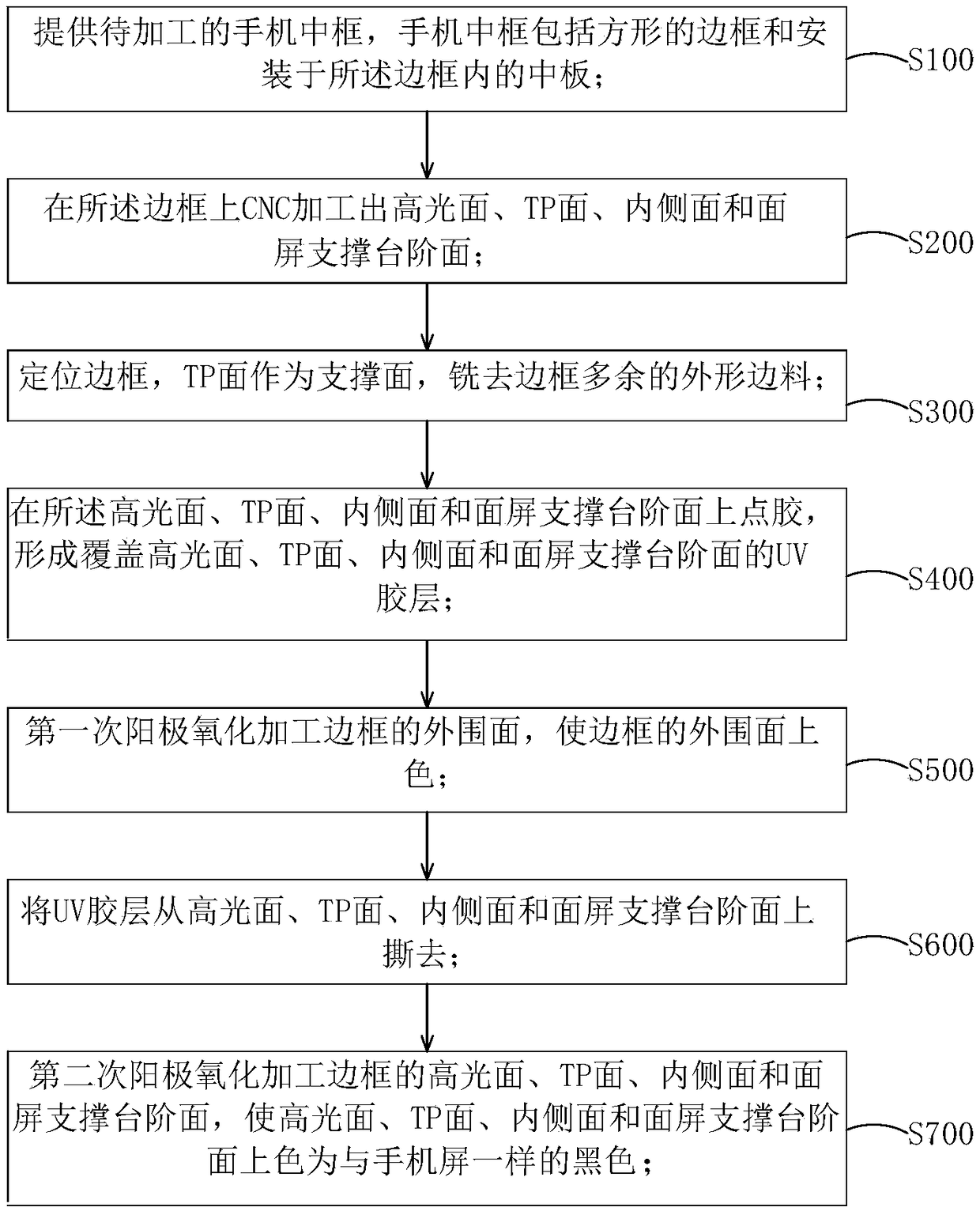

[0047] see image 3 , is the flow chart of the mobile phone middle frame processing process in Embodiment 1 of the present invention, and the mobile phone middle frame processing process specifically includes the following steps:

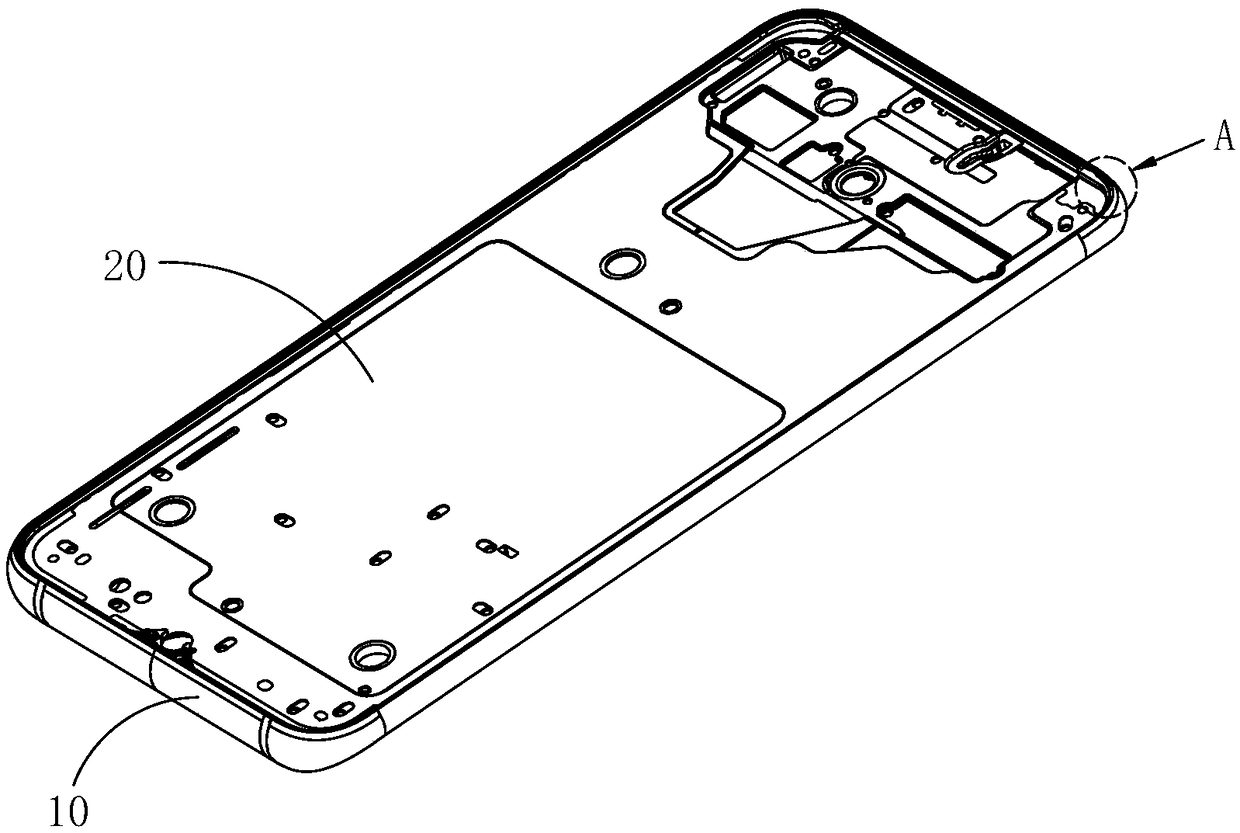

[0048] S100 , providing a mobile phone middle frame to be processed, the mobile phone middle frame to be processed includes a square frame 10 and a middle plate 20 installed in the frame 10 .

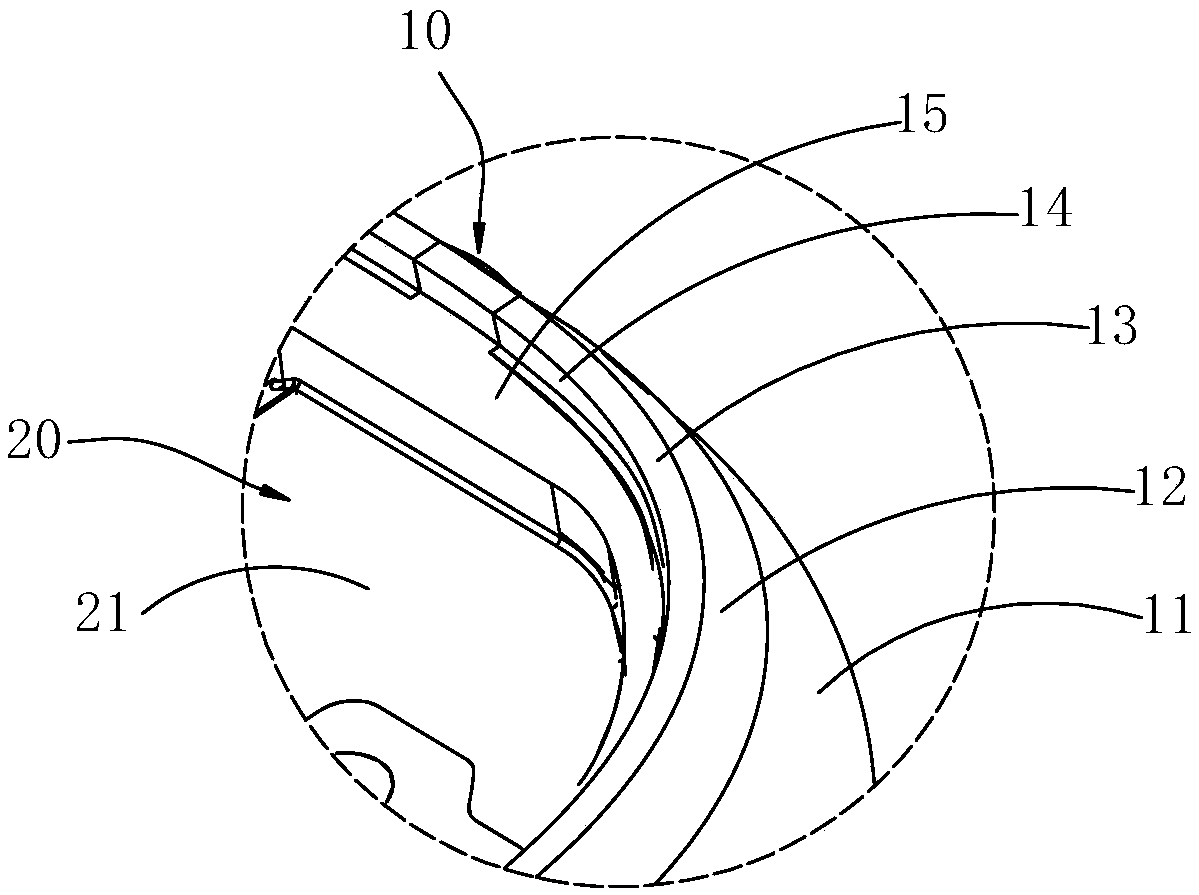

[0049] S200 , machining the high-gloss surface 12 , the TP surface 13 , the inner surface 14 and the screen support step surface 15 on the frame 10 by CNC.

[0050] S300. Positioning the frame 10, the TP surface 13 is used as a positioning support surface, and milling off redundant shape trim of the frame 10.

[0051] By processing the high-gloss surface 12, TP surface 13, inner side surface 14 and face screen support step surface 15 on the frame 10 before the profile of the milling frame 10, the frame 10 can be used when the milling profile is clamped on th...

Embodiment 2

[0063] Figure 4 It is a flow chart of the mobile phone middle frame processing process in Embodiment 2 of the present invention. The differences between this embodiment and Embodiment 1 are:

[0064] Step S400 also includes, forming several drawbars on the UV adhesive layer with glue, so that the UV adhesive layer can be torn off from the frame 10 by pulling the drawbars in a later stage with less effort.

[0065] After S500, before S600, also include steps:

[0066] S501 , irradiating the UV adhesive layer with ultraviolet light until the debonding energy of the UV adhesive layer is reached.

[0067] Specifically, by irradiating the UV adhesive layer with ultraviolet light, the adhesion between the UV adhesive and the frame 10 can be reduced, and when the ungluing energy of the UV adhesive layer is reached, it is convenient for workers to tear off the UV adhesive layer from the frame 10 effortlessly.

Embodiment 3

[0069] Figure 5 It is a flow chart of the mobile phone middle frame processing process in Embodiment 3 of the present invention. The difference between this embodiment and Embodiment 2 is that the UV adhesive layer is irradiated with UV light until the UV adhesive layer loses its viscosity, instead of ultraviolet light irradiation. UV glue layer, until the step after the unbonding energy of the UV glue layer is reached.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com