Automatic sponge separator

A cotton separator and sponge technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problem of high labor intensity, and achieve the effect of reducing labor labor and strong versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

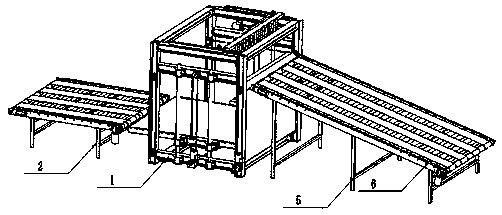

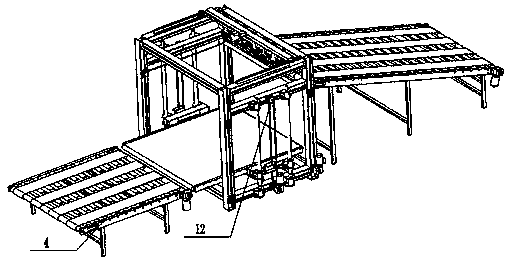

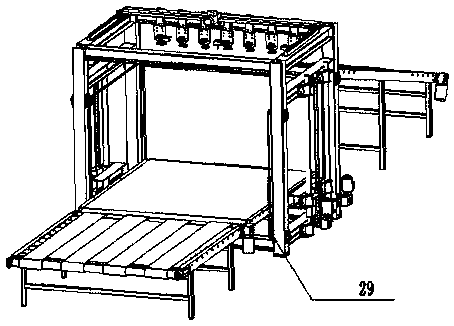

[0030] Such as Figure 1-Figure 8 A kind of automatic sponge distributing machine shown, comprises

[0031] A cotton support 1, the cotton support 1 is a cuboid frame structure composed of several crossbars, longitudinal bars and columns, and a feed conveyor and a discharge conveyor are respectively arranged on both sides of the cotton support 1.

[0032] Feed conveying comprises a feed conveying support 2, and some feed conveying rollers 4 are installed on the feed conveying support 2, and feed conveyor belt 3 is installed on feed conveying roller 4, and feed conveyer belt 3 is installed on The feed conveying motor drive on the feed conveying support 2 works.

[0033] The discharge conveying comprises a discharge conveying support 5, on the discharge conveying support 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com