A kind of equipment and method for preparing graphene and graphene prepared therefrom

A graphene and graphene nanosheet technology, applied in the field of graphene, can solve the problems of high energy consumption, sewage, unenvironmental protection, etc., and achieve the effects of high product quality, reduced dust emissions, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

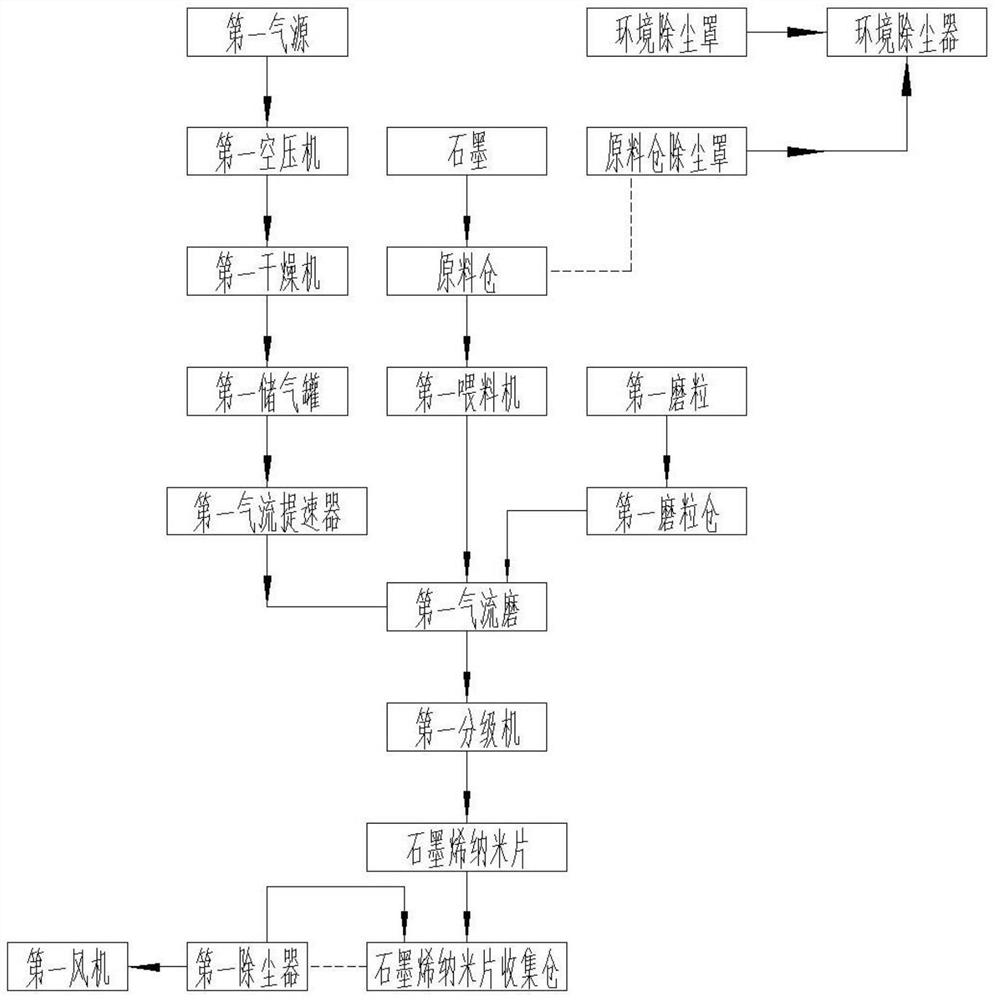

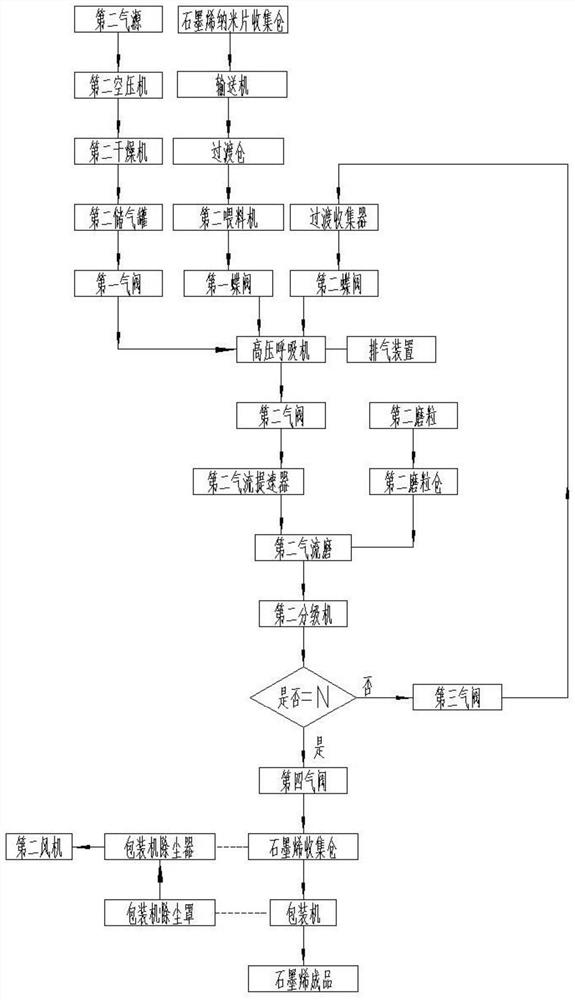

Method used

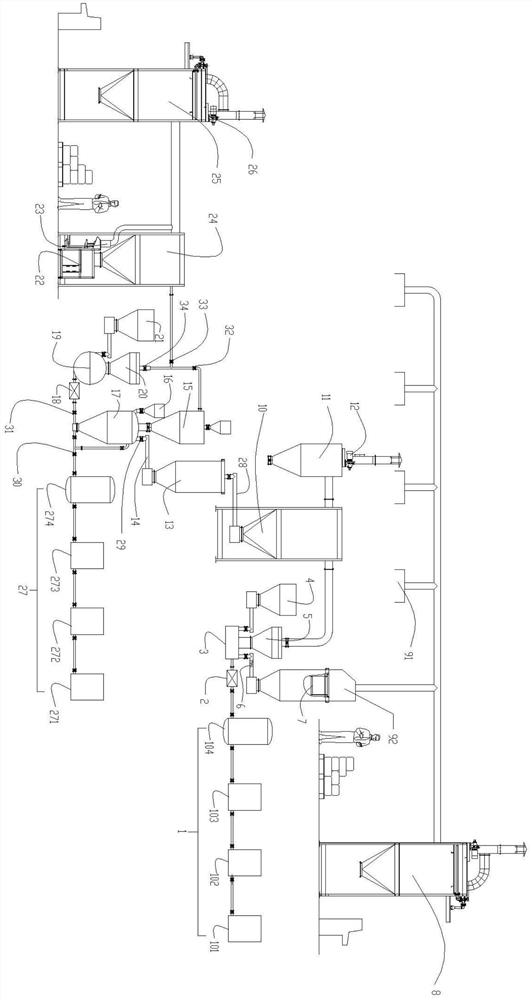

Image

Examples

Embodiment 1

[0069] Flake graphite is selected, the particle size is 200um, the first air source pressure is 0.6MPa, and the airflow velocity is 360m / S after being accelerated by the first airflow speed increaser. The particle size of the first abrasive particle is 22-36um, and the material is diamond powder; the first jet mill is a flat jet mill, and the speed of the first classifier is 4000r / min to generate scaly graphene nanosheets with a thickness of 400- 500 nm.

[0070] Select the above-mentioned flake graphene nanosheets, adjust the pressure of the second air source to 0.6MPa, after the speed is increased by the second air speed increaser, the air flow rate is 250m / S, and the second abrasive grains are selected to have a particle size of 22-36um and the material is gold steel Stone micropowder, the speed of the second classifier is 2000r / min, the number of cycles N is 2, and the single cycle time of N is 9 minutes to obtain multilayer graphene with a thickness of 20-25nm.

Embodiment 2

[0072]Flake graphite is selected, the particle size is 200um, the first air source pressure is 0.6MPa, and the airflow velocity is 360m / S after being accelerated by the first airflow speed increaser. The particle size of the first abrasive particle is 22-36um, and the material is diamond powder; the first jet mill is a flat jet mill, and the speed of the first classifier is 5000r / min to generate scaly graphene nanosheets with a thickness of 300- 400 nm.

[0073] Select the above-mentioned flake graphene nanosheets, adjust the pressure of the second air source to 0.6MPa, and after the speed is increased by the second air speed increaser, the air flow rate is 200m / S, and the second abrasive particles are selected to have a particle size of 22-36um, and the material is gold steel Stone powder, the speed of the second classifier is 2000r / min, the number of cycles N is 15, and the single cycle time of N is 6 minutes to obtain few-layer graphene with a thickness of 3-5nm.

Embodiment 3

[0075] Flake graphite is selected, the particle size is 200um, the first air source pressure is 0.6MPa, and the airflow velocity is 360m / S after being accelerated by the first airflow speed increaser. The first abrasive particle size is 22-36um, and the material is diamond powder; the first jet mill is a flat jet mill, and the first classifier rotates at a speed of 7000r / min to produce scaly graphene nanosheets with a thickness of 250- 300 nm.

[0076] Select the above-mentioned flake graphene nanosheets, adjust the pressure of the second air source to 0.6MPa, after the speed is increased by the second airflow speed increaser, the airflow velocity is 150m / S, and the second abrasive particles are selected to have a particle size of 22-36um, and the material is gold steel Stone micropowder, the speed of the second classifier is 2000r / min, the number of cycles N is 100, and the single cycle time of N is 6 minutes to obtain single-layer graphene with a thickness of 0.3-0.8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com