Thermochromic intelligent thermal-control device based on VO2 film and preparation method of thermochromic intelligent thermal-control device

A thermochromic, VO2 technology, applied in vanadium oxide and other directions, can solve the problems of high reflection at high temperature and low emissivity at high temperature of the film, and achieve the effect of increasing thermal load, low emissivity at low temperature, and high emissivity at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

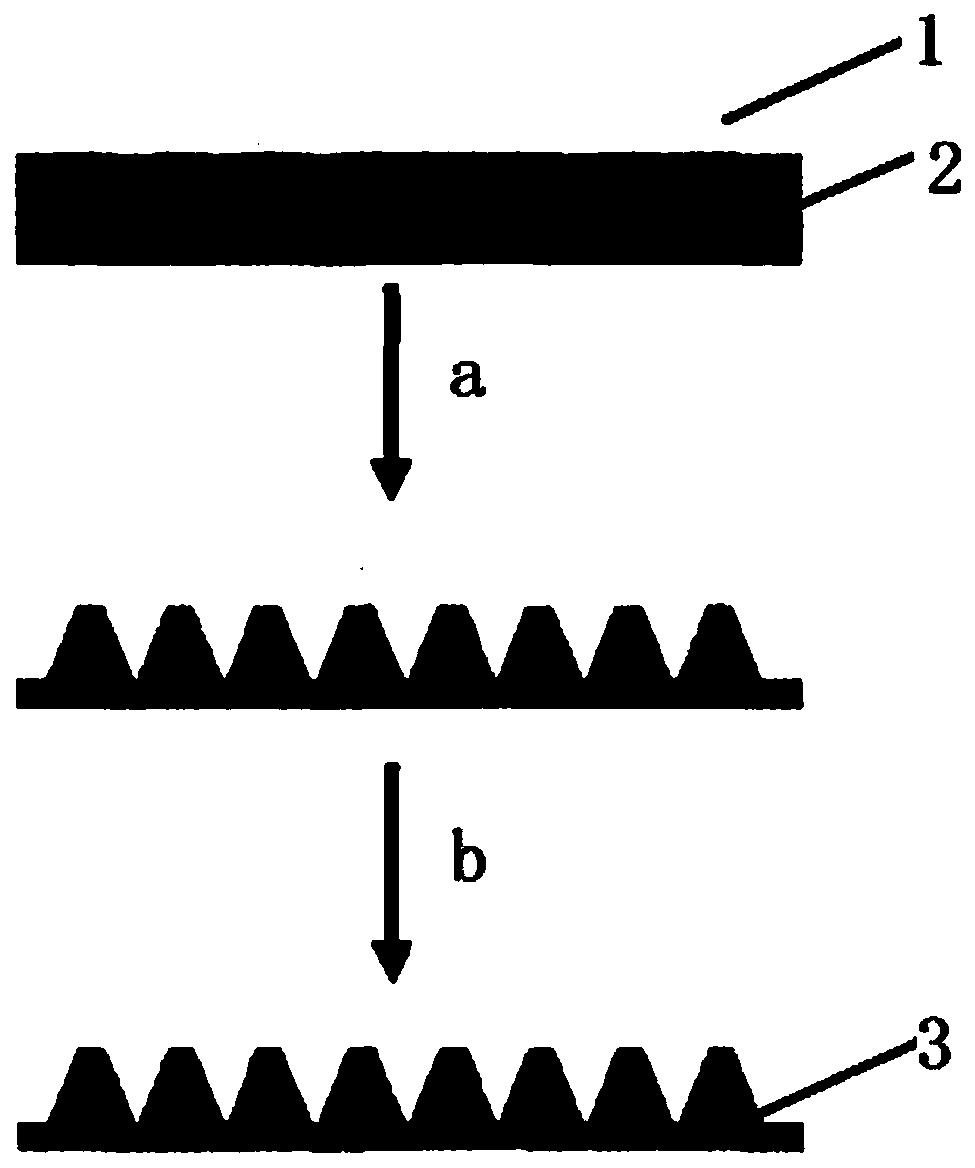

[0033] Specific implementation mode 1: This implementation mode is based on VO 2 The thin-film thermochromic intelligent thermal control device consists of a highly reflective metal base layer, a micro-nano structure VO from bottom to top 2 layer and protective layer composition;

[0034] The micro-nano structure VO 2 The layer is composed of a plurality of micro-nano structural units, and the plurality of micro-nano structural units are uniformly arranged on the upper surface of the highly reflective metal base layer; the shape of the micro-nano structural units is conical, cylindrical or cuboid; when When the shape of the micro-nano structural unit is conical, the diameter of the conical bottom surface is 100nm-1000nm, the height is 20nm-1000nm, the cone angle is 10°-120°, and the adjacent micro-nano structural units are closely arranged; when the said When the shape of the micro-nano structural unit is cylindrical, the diameter of the cylindrical shape is 100nm-1000nm, th...

specific Embodiment approach 2

[0037] Specific embodiment 2: The difference between this embodiment and specific embodiment 2 is that the highly reflective metal base layer is Al, Au, Ag, Mg, Ni, Zn or Cu; the protective layer is Al 2 o 3 , SiO 2 , ZrO 2 , Nb 2 o 5 or HfO 2 , the upper surface of the protective layer and the micro-nano structure VO 2 The distance between the upper surfaces of the layers is 20nm-200nm. Others are the same as in the second embodiment.

[0038] The highly reflective metal base layer described in this embodiment is infrared highly reflective metal.

specific Embodiment approach 3

[0039] Specific implementation mode three: this implementation mode is based on VO 2 The preparation method of the thermochromic intelligent thermal control device of the film is carried out according to the following steps:

[0040] 1. Clean the substrate:

[0041] Electropolishing is used to polish the surface of the highly reflective metal base layer until the reflectance of the polished high reflective metal base layer in the infrared band of 2.5 microns to 25 microns reaches more than 0.7, and the pretreated metal base layer is obtained;

[0042] 2. VO 2 Film preparation:

[0043] When the frequency is 50Hz~500Hz, the pulse width is 40 microseconds~500 microseconds, the power is 50W~500W, the voltage is 100V~1000V, the temperature is 300℃~450℃, the pressure is 1Pa~2Pa, and the argon gas flow rate is 80sccm~ Under the conditions of 200 sccm and oxygen flow rate of 2 sccm ~ 10 sccm, deposit VO on the surface of the pretreated metal base layer 2 film;

[0044] 3. Micro-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com