Odorless model sponge rubber for conductive shoe and preparation method and application thereof

A technology of conductive shoes and models, applied in the field of rubber processing, to achieve low cost and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

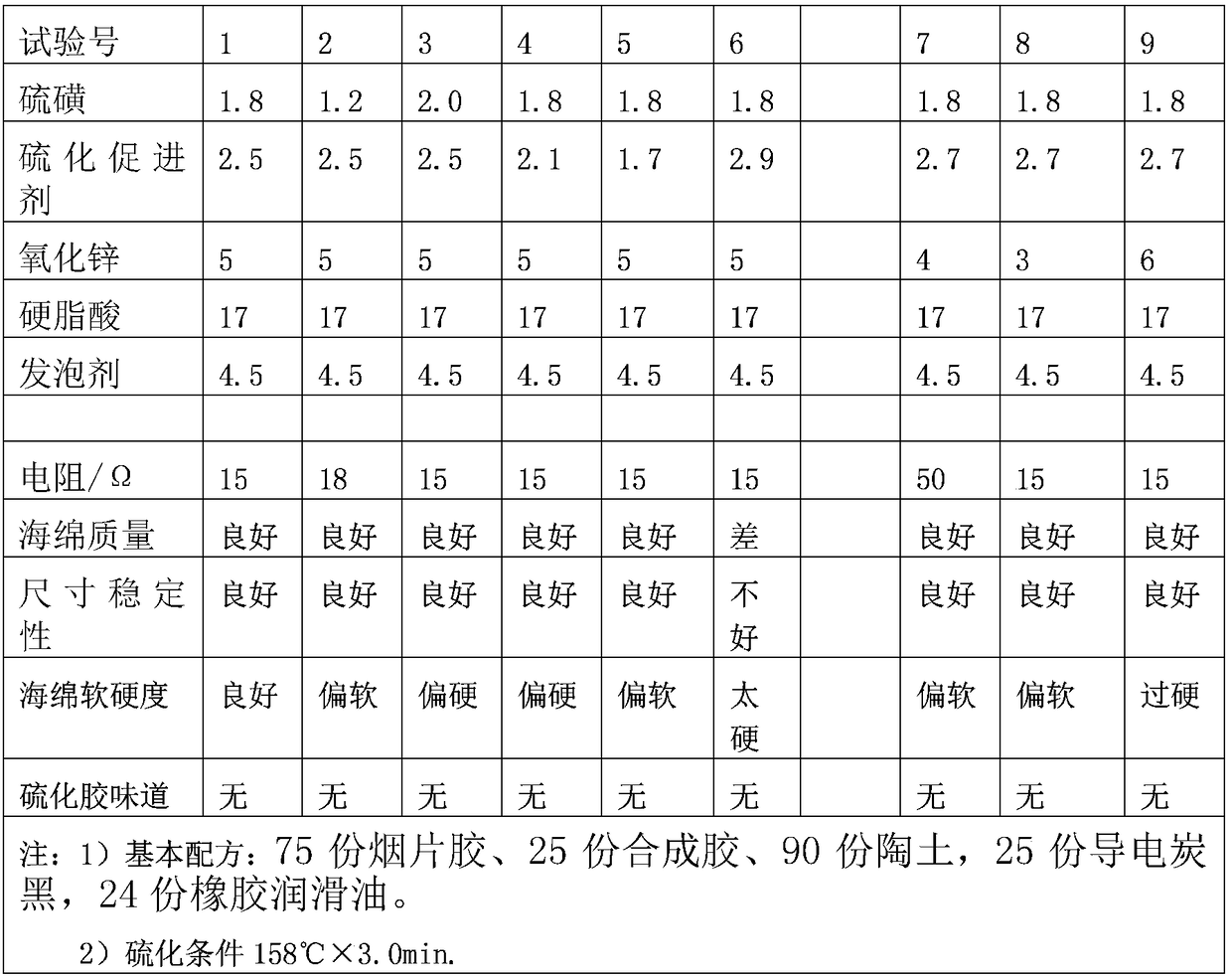

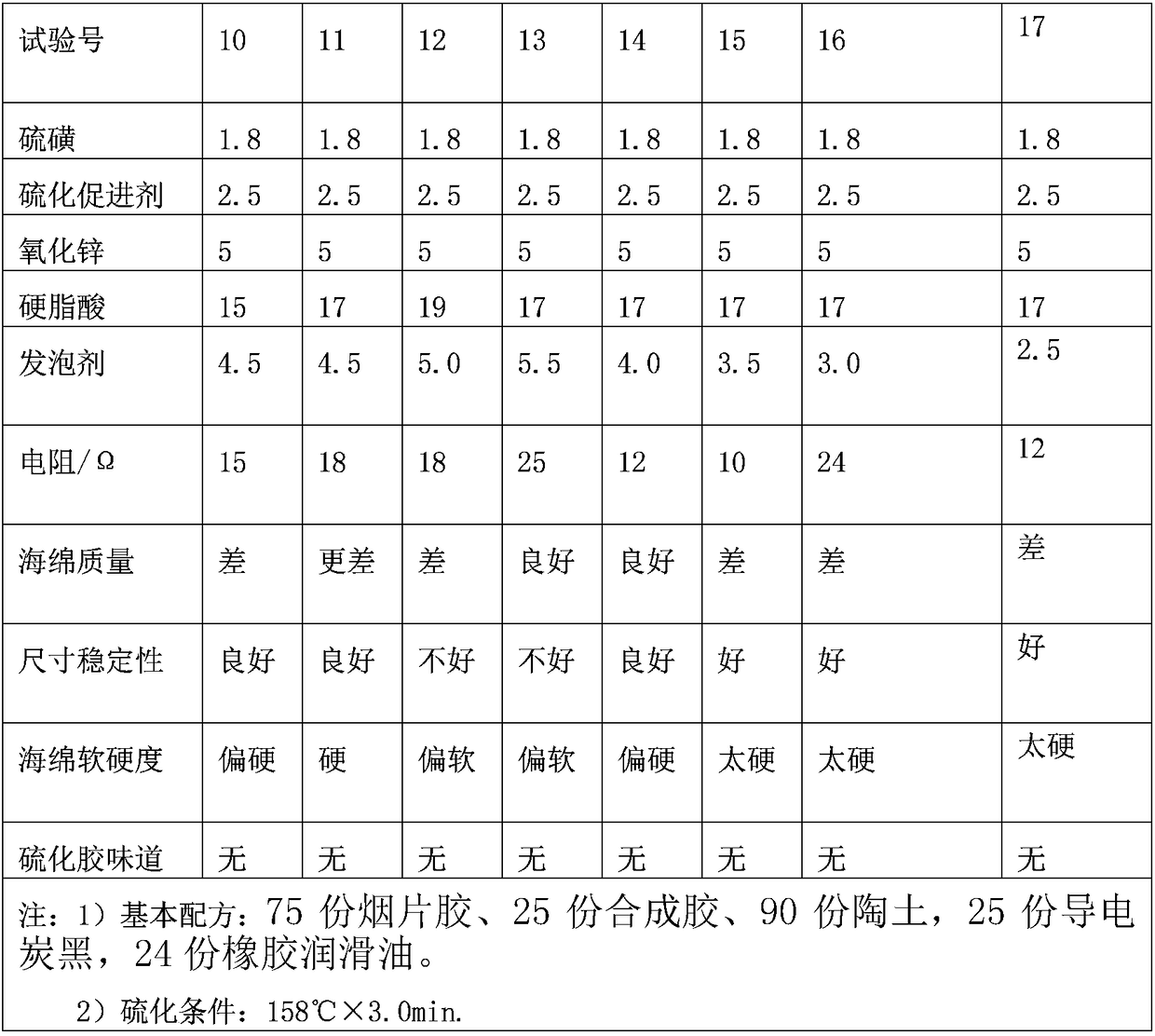

[0013] Embodiments of the present invention: odorless model sponge rubber for conductive shoes, calculated in parts by weight, including 75 parts of smoked sheet rubber, 25 parts of synthetic rubber, 1.8 parts of sulfur, 2.5 parts of vulcanization accelerator, 5 parts of zinc oxide, 17 parts Stearic acid, 90 parts of clay, 4.5 parts of foaming agent, 25 parts of conductive carbon black, 24 parts of rubber lubricating oil.

[0014] Every 2.5 parts of vulcanization accelerator consists of 0.5 parts of accelerator M, 1.5 parts of accelerator CBS and 0.5 parts of accelerator D.

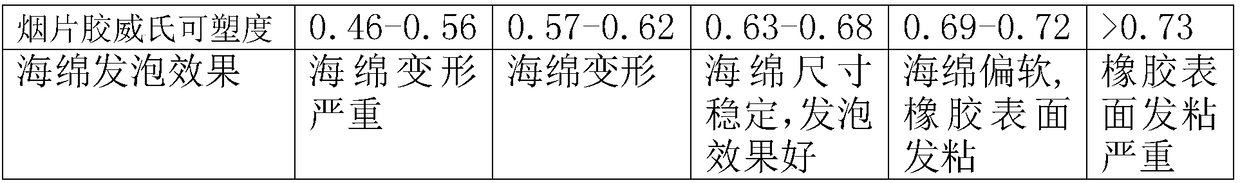

[0015] The preparation method of the odorless model sponge rubber material for conductive shoes is to take each component according to the above weight fraction, and to get each component according to the above weight fraction, 1) prepare conductive carbon black masterbatch: mix 1 / 2 of the smoked sheet glue Masticate on an open rubber mixer with a temperature not higher than 50°C until the Vickers plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com