Road friction increasing type road roller

A road roller and friction technology, applied in the field of road rollers that increase road friction, can solve problems that affect passengers' rest, decrease driver's response ability, increase traffic accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

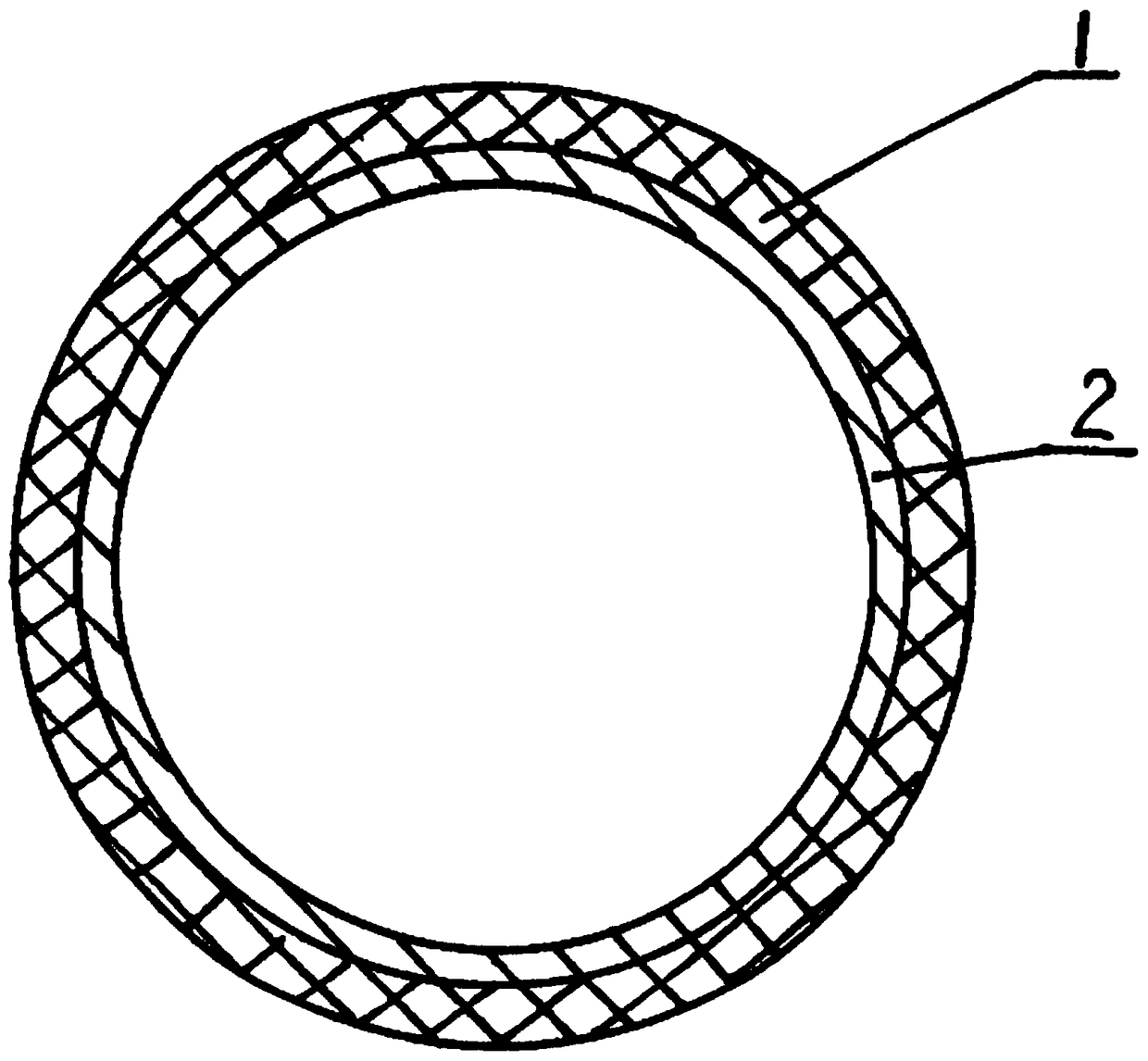

[0007] Specific implementation method: from figure 1 It can be seen from the figure that the road roller body that increases road friction is composed of a steel wheel 2, which is characterized in that: a layer of elastic rubber layer 1 is provided on the surface of the steel wheel 2, and the rubber layer is The split detachable structure, the surface of the rubber layer has a prominent pattern. In this way, in the process of flattening and compacting the slurry seal layer, the pointed aggregate in the slurry-like mixture of the slurry seal layer can be flattened and compacted, thereby improving the smoothness of the slurry seal layer The degree of density and compaction will not affect the internal structure of the slurry seal, which will not only greatly shorten the construction time, but also improve the working efficiency of the road roller, and at the same time, the construction cost will be greatly reduced. Such a slurry seal will effectively reduce the noise generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com