Main cable strand anchoring device of suspension bridge

An anchoring device and suspension bridge technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problem that the main cable anchoring device is no longer applicable, and achieve the effect of simple and reliable force bearing, simple construction process and clear force transmission path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

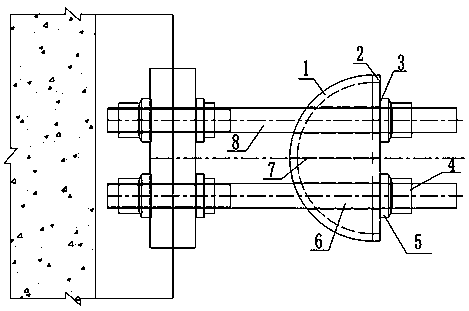

[0035] The radius of the outer arc of the thigh boot is 80d to 100d (d is the diameter of the steel wire), the horizontal length of the part beyond the semicircular arc is 20 to 100mm, the radius of the bottom of the groove is 70d to 90d, and the thickness of the boot is 400 to 600mm.

[0036] Two grooves are arranged, and the section is arranged in a trapezoidal shape. The distance between the edge of the groove and the edge of the femoral boot is 10-50mm.

[0037] The hole diameter of the tie rod of the stock shoe is 10-20mm larger than the diameter of the tie rod, the hole is arranged near the quarter point, and the depth of the notch of the gasket is 4-10mm. The diameter of the hole in the center of the thigh boot is 6-10 mm.

[0038] Perforations with a diameter of 20-40mm are respectively opened on the outer sides of the openings of the two tie rods to meet the needs of temporary anchoring and construction hoisting.

Embodiment 2

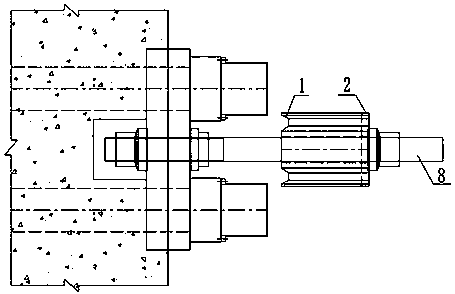

[0040] The radius of the outer arc of the thigh boot is 80d to 100d (d is the diameter of the steel wire), the horizontal length of the part beyond the semicircular arc is 20 to 100mm, the radius of the bottom of the groove is 70d to 90d, and the thickness of the boot is 400 to 600mm.

[0041] Two grooves are arranged, and the cross-section is arranged in a rectangle. The distance between the edge of the groove and the edge of the femoral boot is 10-50mm.

[0042] The hole diameter of the tie rod of the stock shoe is 10-20mm larger than the diameter of the tie rod, the hole is arranged near the quarter point, and the depth of the notch of the gasket is 4-10mm. The diameter of the hole in the center of the thigh boot is 6-10 mm.

[0043] Set 2 to 4 screw holes between M20 and M48 on both sides of the stock boot to meet the needs of temporary anchoring and hoisting during construction.

Embodiment 3

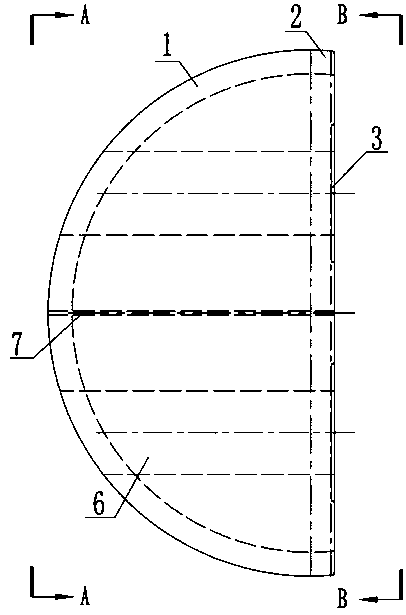

[0045] The radius of the outer arc of the thigh boot is 80d to 100d (d is the diameter of the steel wire), the horizontal length of the part beyond the semicircular arc is 20 to 100mm, the radius of the bottom of the groove is 70d to 90d, and the thickness of the boot is 400 to 600mm.

[0046] Two grooves are arranged, and the section is arranged in a trapezoidal shape. The distance between the edge of the groove and the edge of the femoral boot is 10-50mm.

[0047] The hole diameter of the tie rod of the stock shoe is 10-20mm larger than the diameter of the tie rod, the hole is arranged near the quarter point, and the depth of the notch of the gasket is 4-10mm. The diameter of the hole in the center of the thigh boot is 6-10 mm.

[0048] Set 2 to 4 screw holes between M20 and M48 on both sides of the stock boot to meet the needs of temporary anchoring and hoisting during construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com