Connecting assembly and scanning electron microscope main rack

A technology for connecting components and scanning electron microscopes, which is applied in the direction of connecting members, thin plate connections, mechanical equipment, etc., can solve the problems of inconvenient installation and disassembly of the main frame and the column, and achieve the effect of reliable connection and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

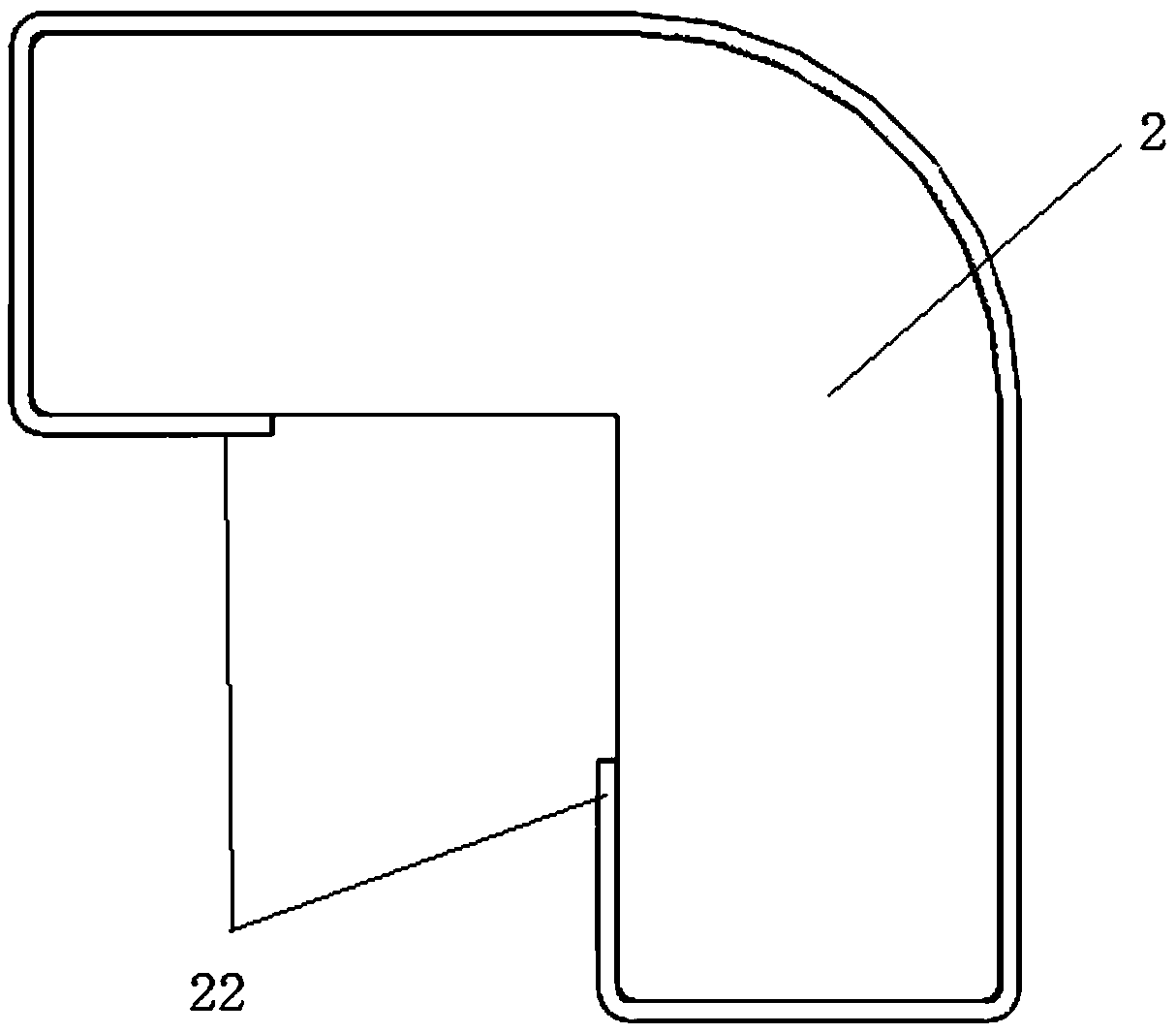

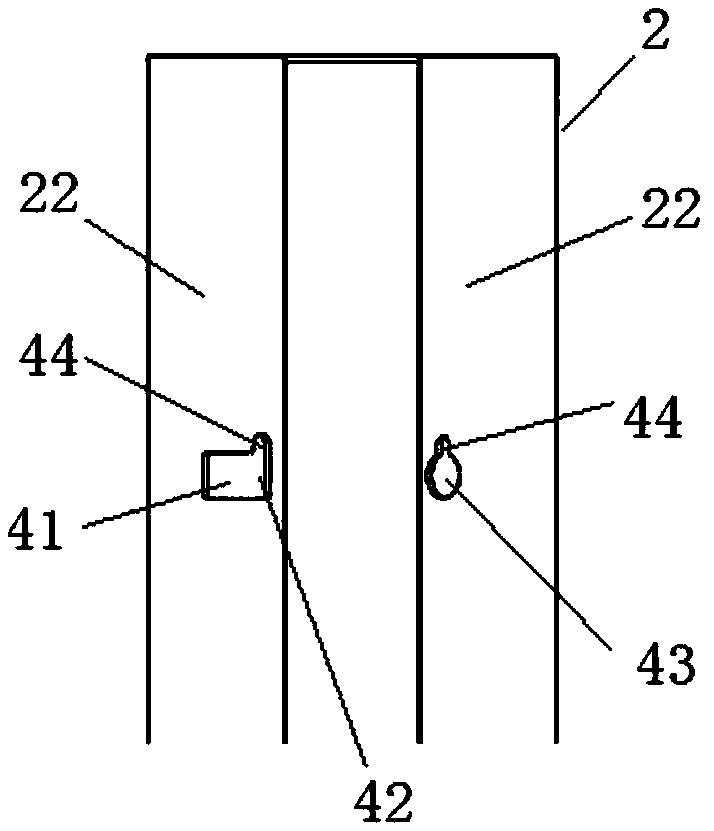

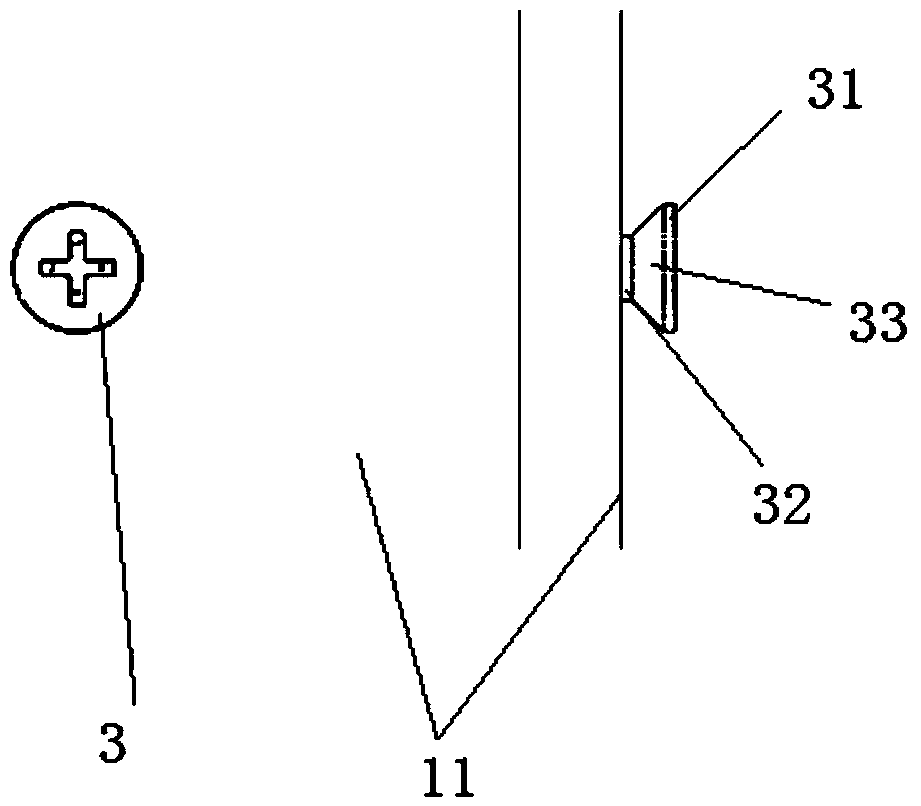

[0039] A connection component of this embodiment, such as figure 1 - Figure 4 As shown, it is arranged on the first piece 1 and the second piece 2, the first piece 1 has a group of adjacent two first side surfaces 11; the second piece 2 is L-shaped, with adjacent The two second sides 22 connected to the two first sides 11 , the inner sides of the second sides 22 are connected to the first side 11 . The connecting assembly includes a first connecting piece 3 , a second connecting piece and a sliding groove 41 .

[0040] There are two first connecting parts 3 , which are respectively arranged on the two first side surfaces 11 , and the connecting line between the two first connecting parts 3 is parallel to the horizontal plane. The first piece 1 includes a head 31 , a connecting portion 33 and a fixing portion 32 . The head 31 is used to be inserted into the second connector, the fixing part 32 is fixedly connected to the first part 1, and the connecting part 33 is arranged ...

Embodiment 2

[0054] The scanning electron microscope main frame of the present embodiment, as Figure 5 As shown, the connection assembly of the first embodiment is included.

[0055] The main body of the main frame is the first piece 1, which is used to set up the scanning electron microscope.

[0056] The upright column is the second part 2, and the upright column is L-shaped, and is hooked to the main frame main body through the connecting assembly.

[0057] In this embodiment, the main body of the main frame has four edges, and upright columns need to be arranged at the four edges.

[0058] When the column is installed on the main body of the main frame, it can rely on the gravity of the column and the V-shaped groove to self-lock on the main body of the main frame. The installation and disassembly of the column are relatively simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com