Bending stainless steel soft pipe

A technology of stainless steel and soft tubes, applied in the direction of slender components, building components, etc., can solve the problems of low strength, high cost of copper tubes, and inability to bend well, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

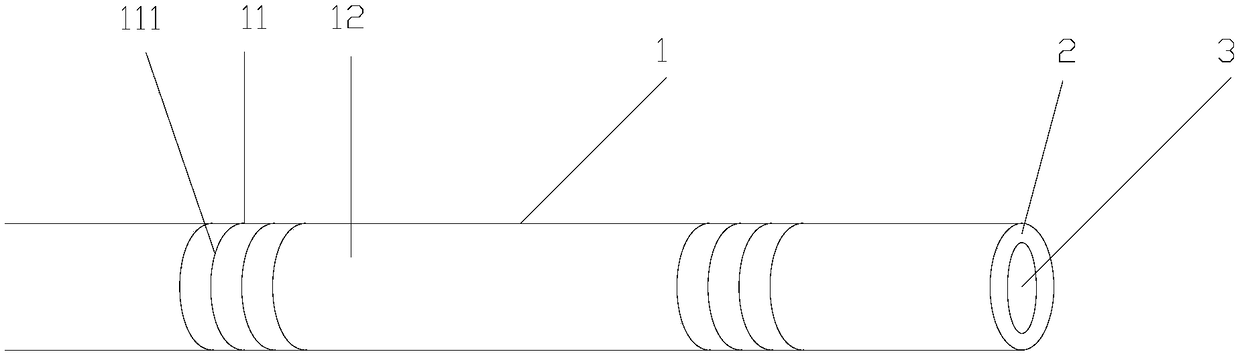

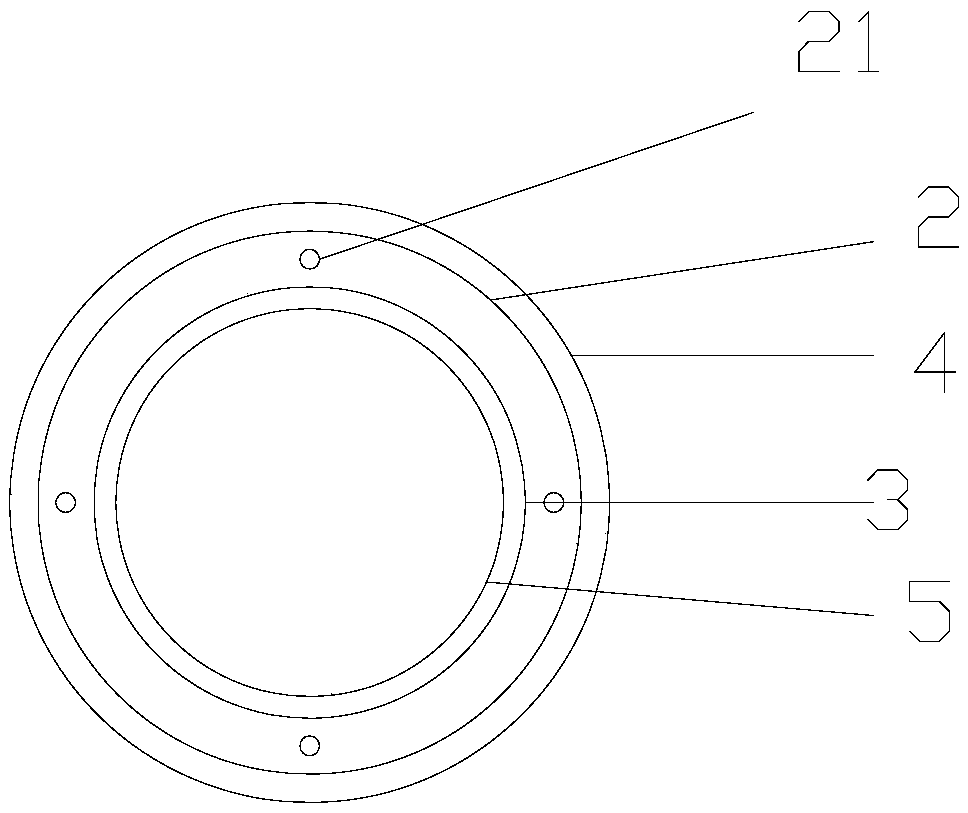

[0023] refer to figure 1 , the embodiment of the present invention provides a bendable stainless steel flexible pipe, which is characterized in that it includes a pipe body 1, a nozzle 2, a pipe hole 3, an insulating protective layer 4, and a water blocking layer 5. The pipe body 1 includes several A section of bendable part 11 and several sections of straight pipe part 12, said bendable part 11 is provided with several creases 111 for easy bending, the outer surface of said straight pipe part 12 is a smooth structure, said straight pipe part 12 is longer than the bendable part 11, the two ends of the pipe body 1 are provided with nozzles 2, the center of the nozzle 2 is provided with a pipe hole 3, and the inner surface of the pipe hole 3 is provided with a water blocking layer 5, so The outer surface of the pipe body 1 is provided with an insulating protective layer 4 , the cross section of the nozzle 2 and the pipe hole 3 is circular, and the plane where the nozzle 2 is loc...

Embodiment 2

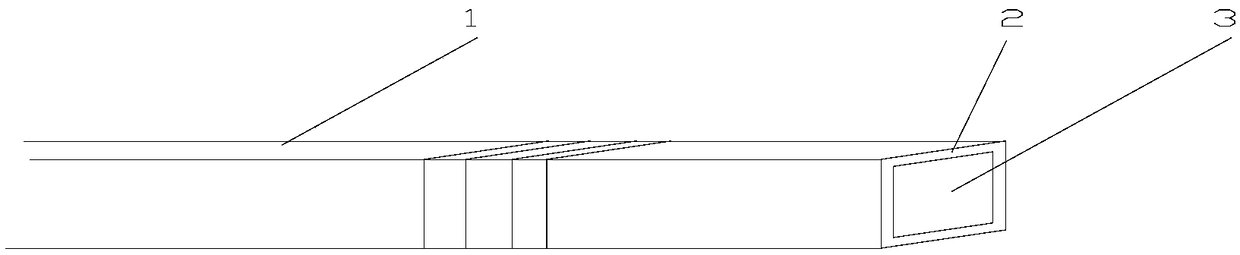

[0025] refer to image 3 , The difference between this embodiment and Embodiment 1 is that: the cross section of the nozzle 2 and the tube hole 3 is rectangular.

Embodiment 3

[0027] refer to Figure 4 , The difference between this embodiment and Embodiment 1 is that the cross-sections of the nozzle 2 and the tube hole 3 are semicircular.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap