A Distributed Thermal Pipeline Leakage Monitoring System

A thermal pipeline and monitoring system technology, applied in heating systems, heating methods, heat measurement, etc., can solve problems such as complex system structure, high operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

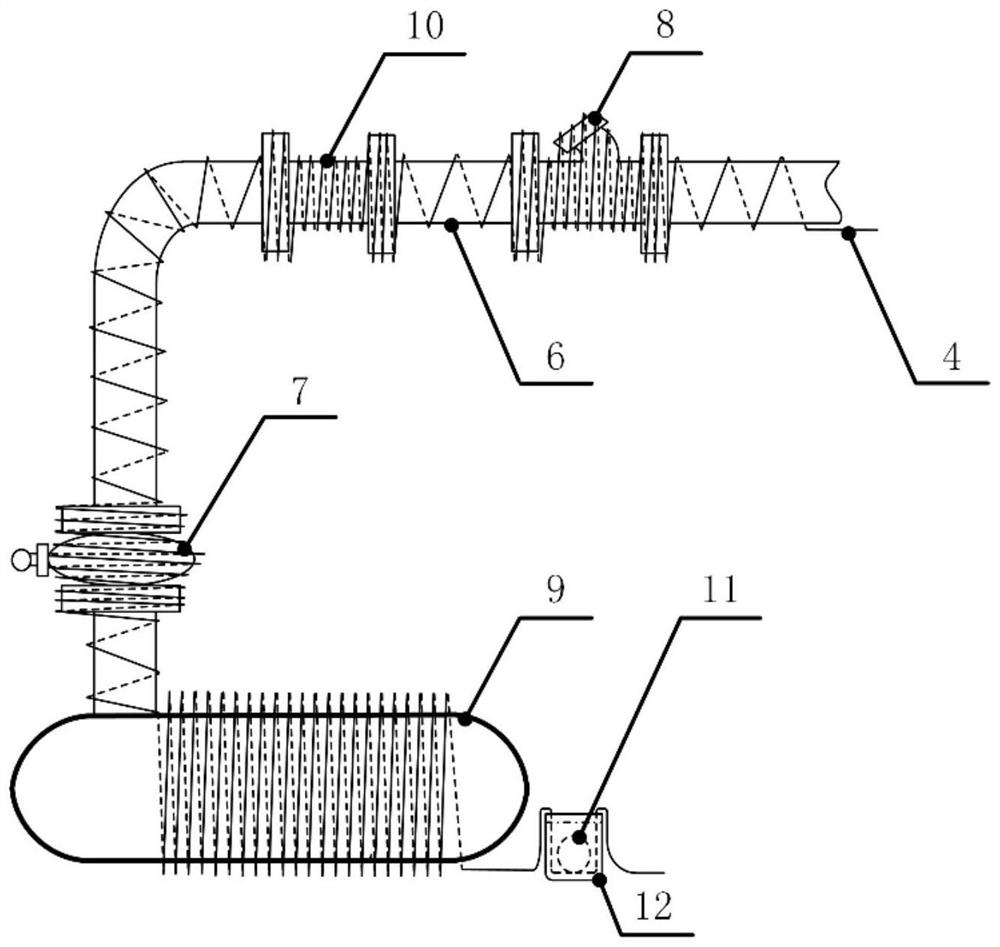

[0044] The present invention will be further elaborated below in conjunction with the accompanying drawings.

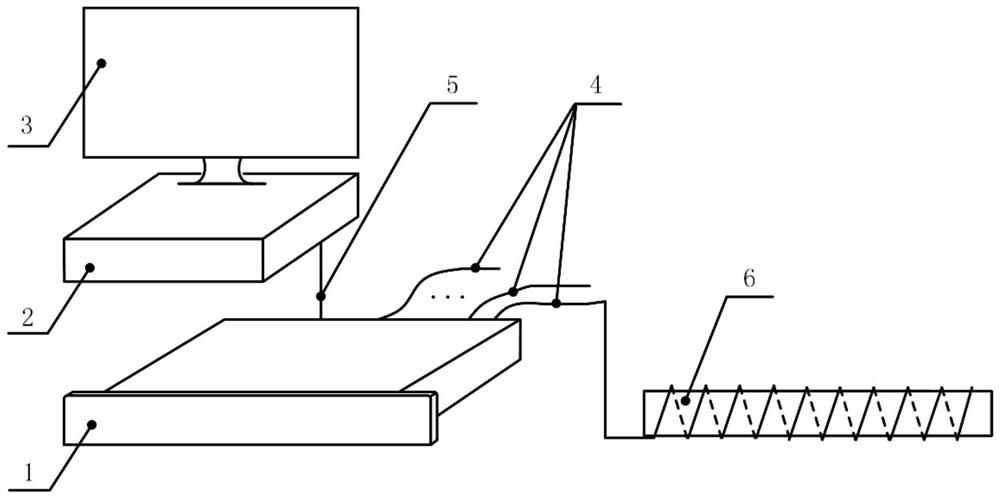

[0045] Such as figure 1 As shown, the present invention provides a distributed thermal pipeline leakage monitoring system, which includes an optical fiber temperature measurement host 1 , an industrial computer 2 , a display 3 , a temperature measurement optical cable 4 and a network cable 5 . in:

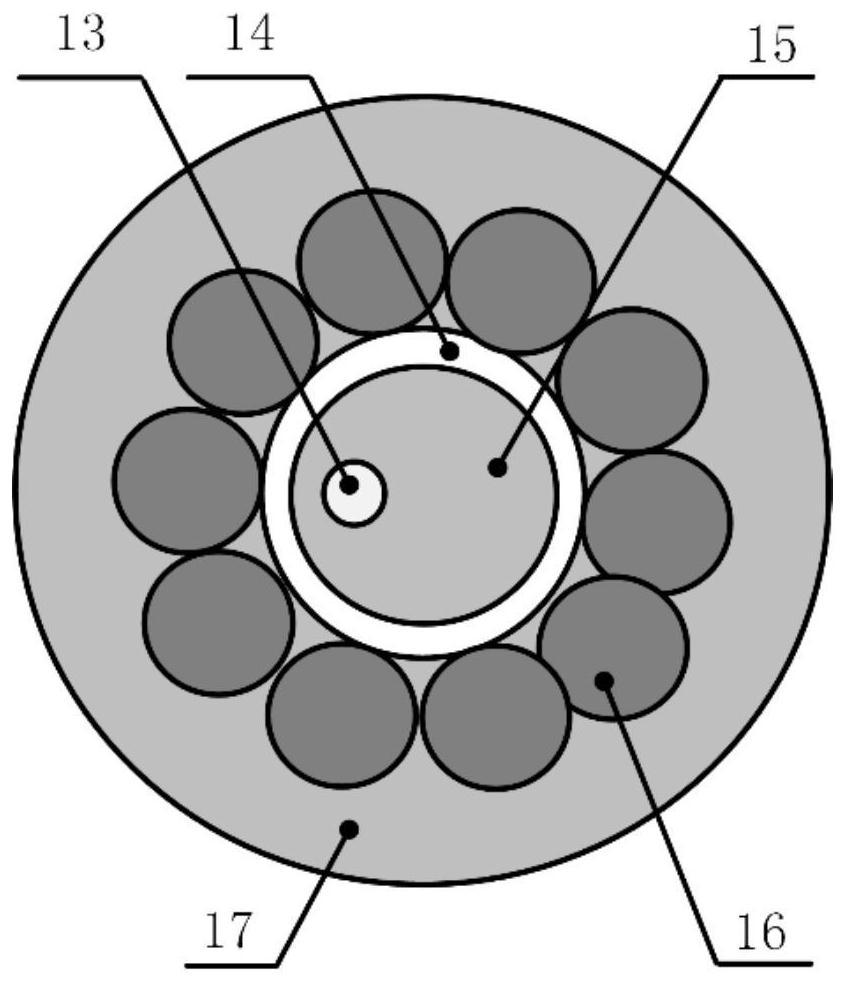

[0046] The optical fiber temperature measurement host 1 includes N temperature measurement channels, and each temperature measurement channel is connected to a temperature measurement optical cable 4. The temperature measurement optical cable 4 is laid along the entire pipeline with the thermal pipeline 6 as the carrier. Send pulsed light signals, collect the scattered light sent back from the temperature measuring optical cable 4 in real time, obtain the temperature and temperature change rate numerical curves of the entire line on the thermal pipeline 6 according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com