Distributed thermal pipeline leakage monitoring system

A technology for thermal pipelines and monitoring systems, applied in heating systems, household heating, heating methods, etc., can solve the problems of high operation and maintenance costs, complex system structure, etc., and achieve highly intelligent and intensive management and environmental adaptation. The effect of strong performance, guaranteeing safety and high-quality operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with the accompanying drawings.

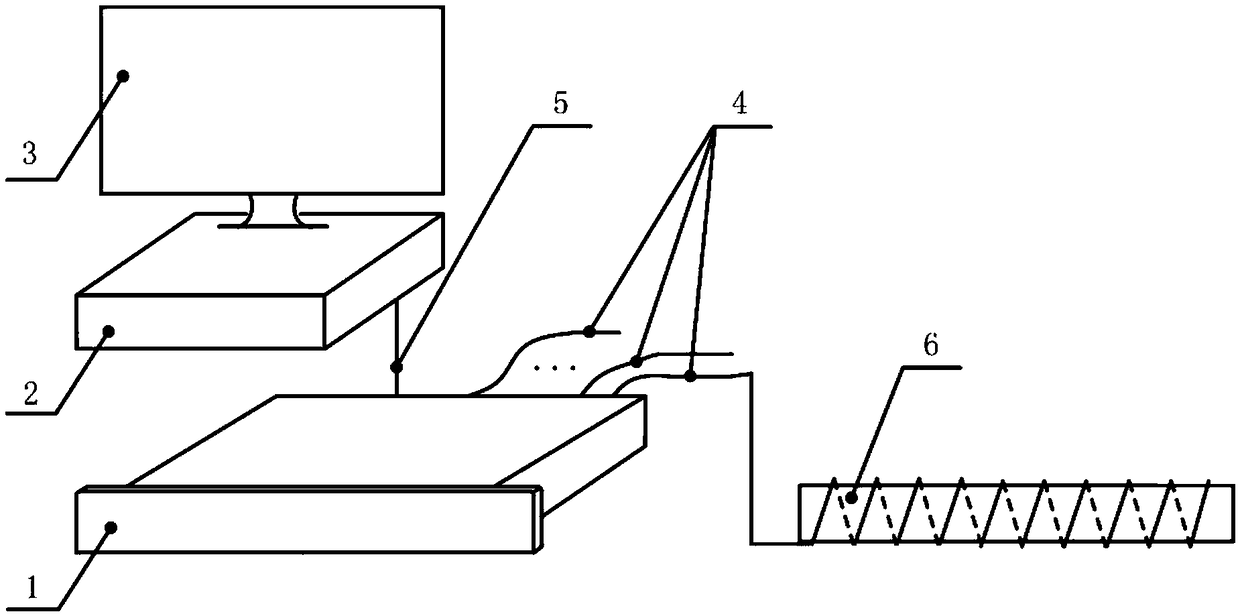

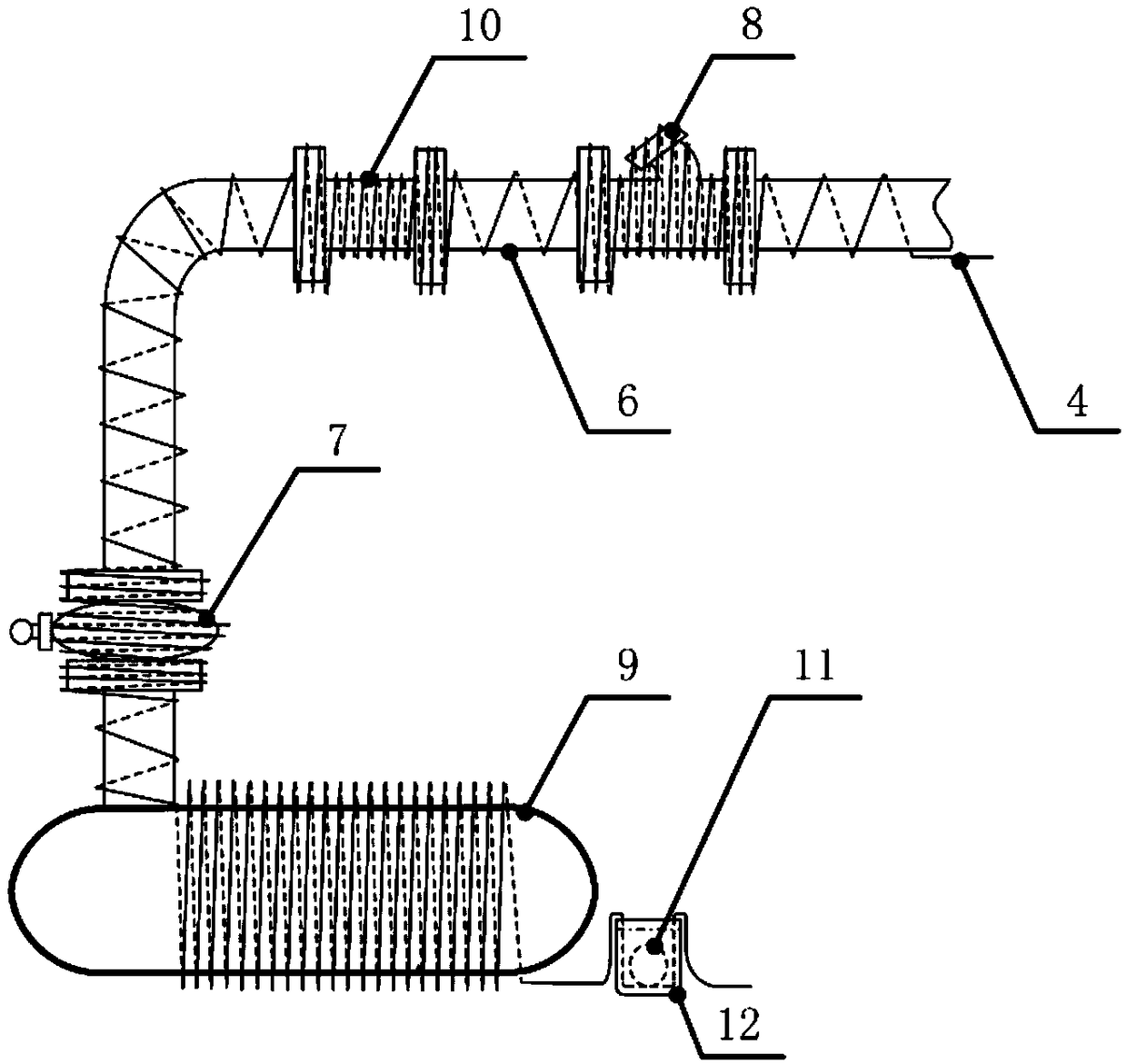

[0045] Such as figure 1 As shown, the present invention provides a distributed thermal pipeline leakage monitoring system, which includes an optical fiber temperature measurement host 1 , an industrial computer 2 , a display 3 , a temperature measurement optical cable 4 and a network cable 5 . in:

[0046] The optical fiber temperature measurement host 1 includes N temperature measurement channels, and each temperature measurement channel is connected to a temperature measurement optical cable 4. The temperature measurement optical cable 4 is laid along the entire pipeline with the thermal pipeline 6 as the carrier. Send pulsed light signals, collect the scattered light sent back from the temperature measuring optical cable 4 in real time, obtain the temperature and temperature change rate numerical curves of the entire line on the thermal pipeline 6 according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com