Continuous production type ice maker machine

An ice machine and ice bucket technology, which is applied in ice making, ice making, ice storage/distribution, etc., can solve the problems of poor effect, inability to realize continuous ice production, and low efficiency, so as to achieve high efficiency and ensure ice making Effect and efficiency, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

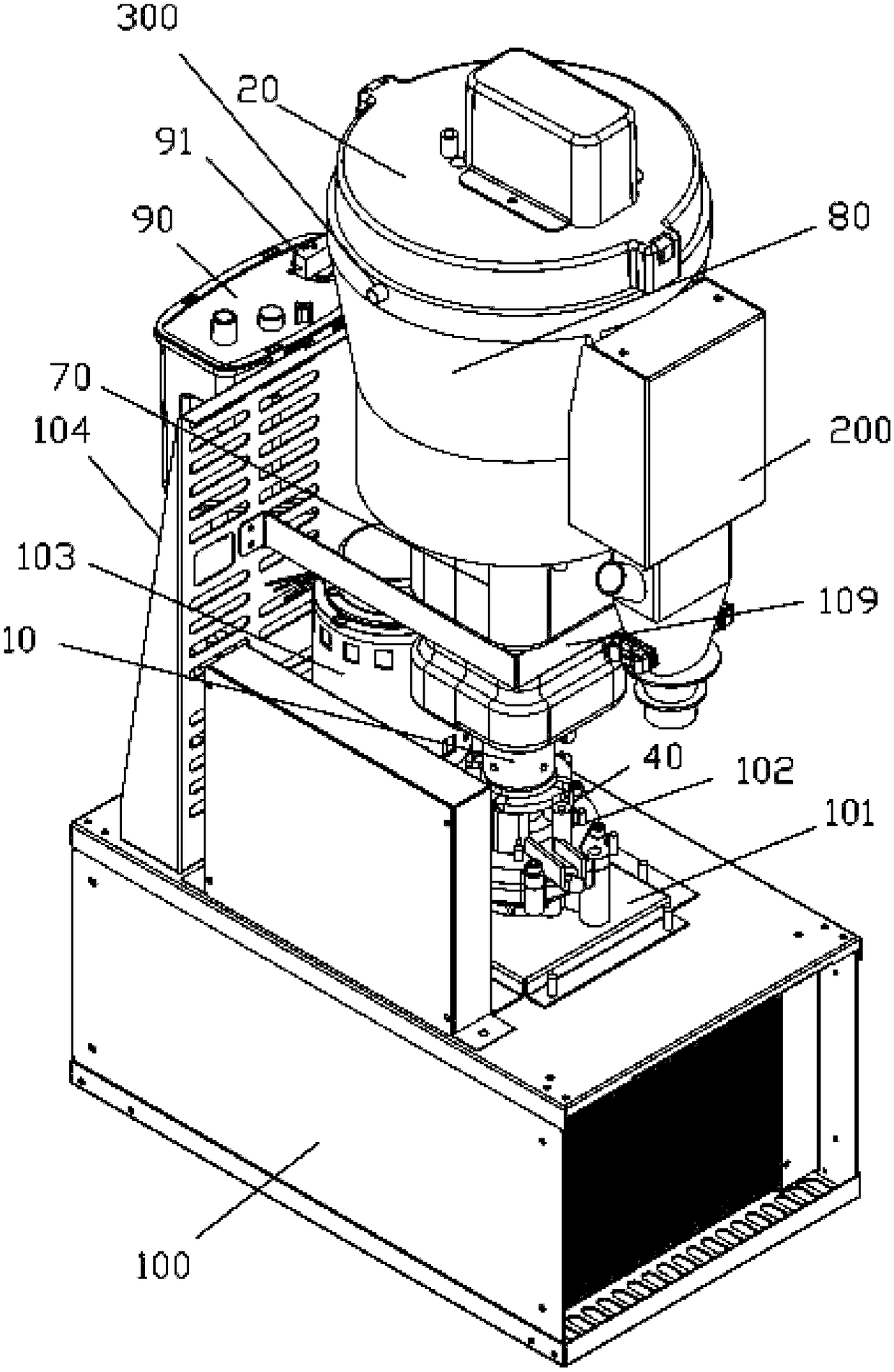

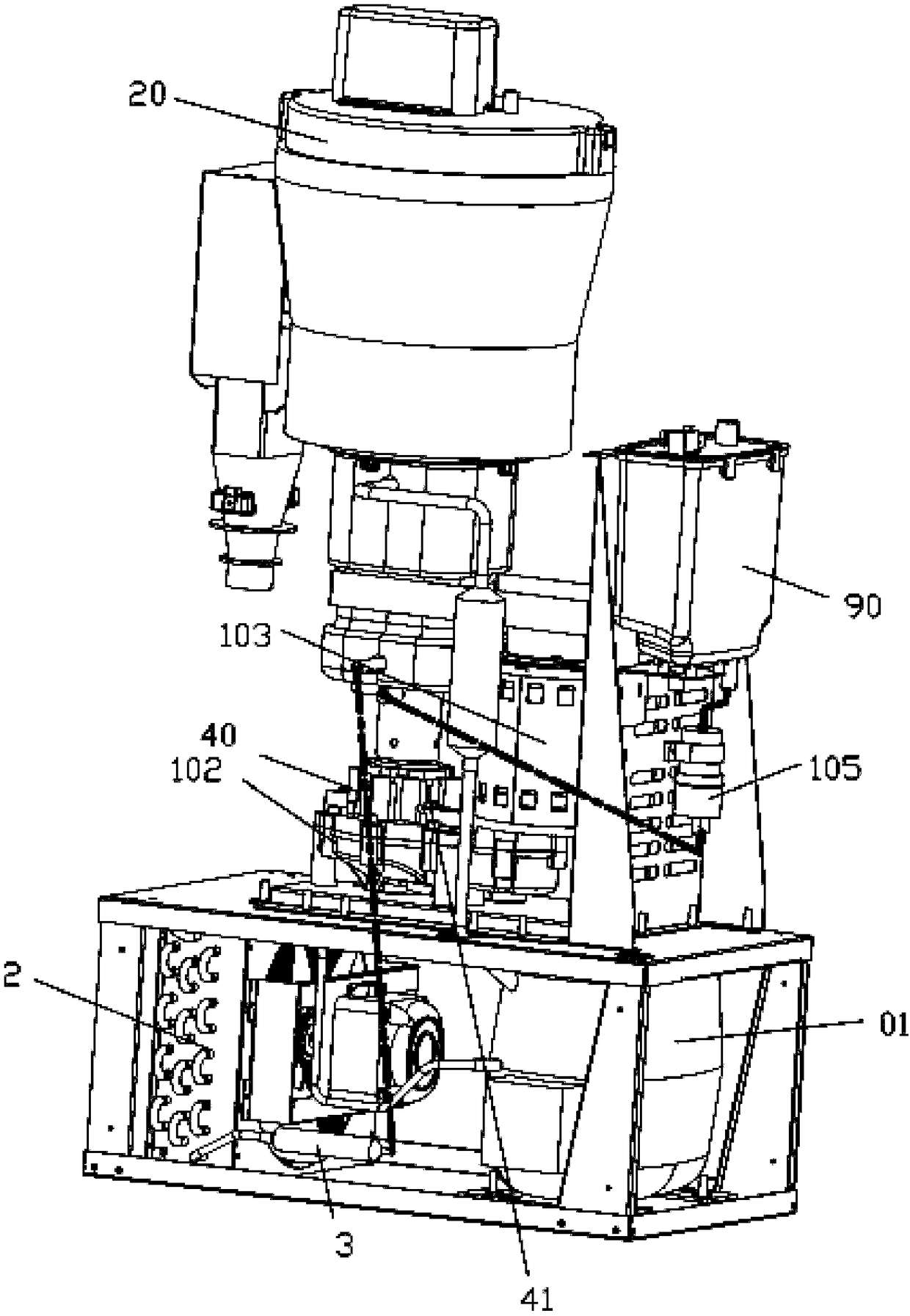

[0046] Example, see as figure 1 with 21 As shown, a continuous production type ice maker includes a bottom main base 100. The top surface of the bottom main base 100 is fixed with a connecting base 101, and the top surface of the connecting base 101 is fixed with a reducer 102 and a reducer 102. A main driving motor 103 is fixed on the upper part, and the output shaft of the main driving motor 103 is connected with the input gear of the reducer 102;

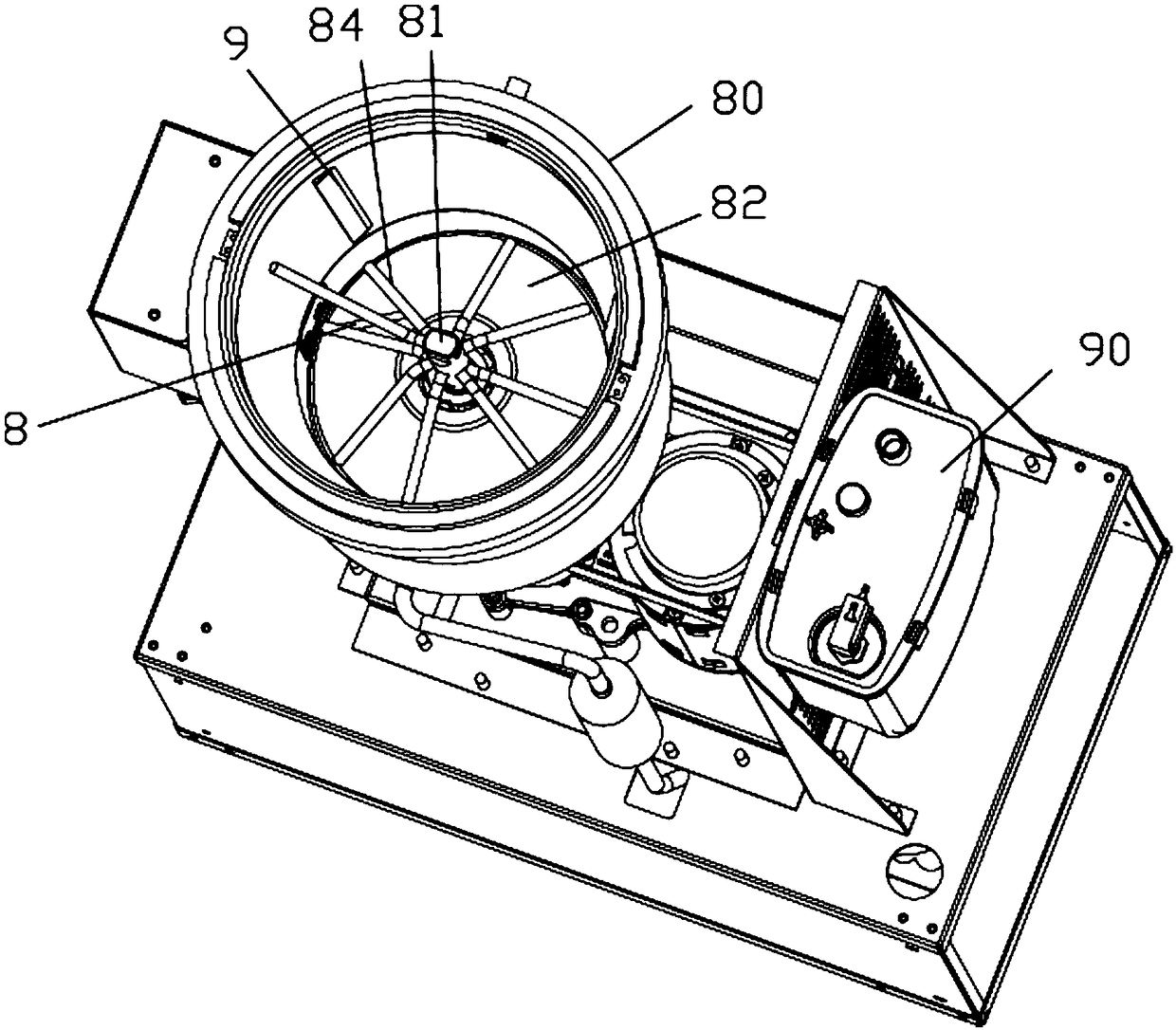

[0047] A connecting sleeve 41 is fixed on the motor reducer connecting seat 40 on one side of the reducer 102, the output shaft 42 of the reducer 102 is in the connecting sleeve 41, the main cylinder 10 is installed on the connecting sleeve 41, and the main cylinder An ice screw 30 is installed in 10, an outer protective sleeve 70 is installed on the outer part of the main cylinder 10, an ice storage bucket 80 is fixed on the top surface of the outer protective sleeve 70, and the top of the main cylinder 10 is inserted into the stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com