An Electromagnetic Ultrasonic and Pulsed Eddy Current Composite Detection Sensor

A pulsed eddy current and electromagnetic ultrasonic technology, which is used in material analysis by electromagnetic means, analysis of solids and instruments using sonic/ultrasonic/infrasonic waves, etc. The effect of value and signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

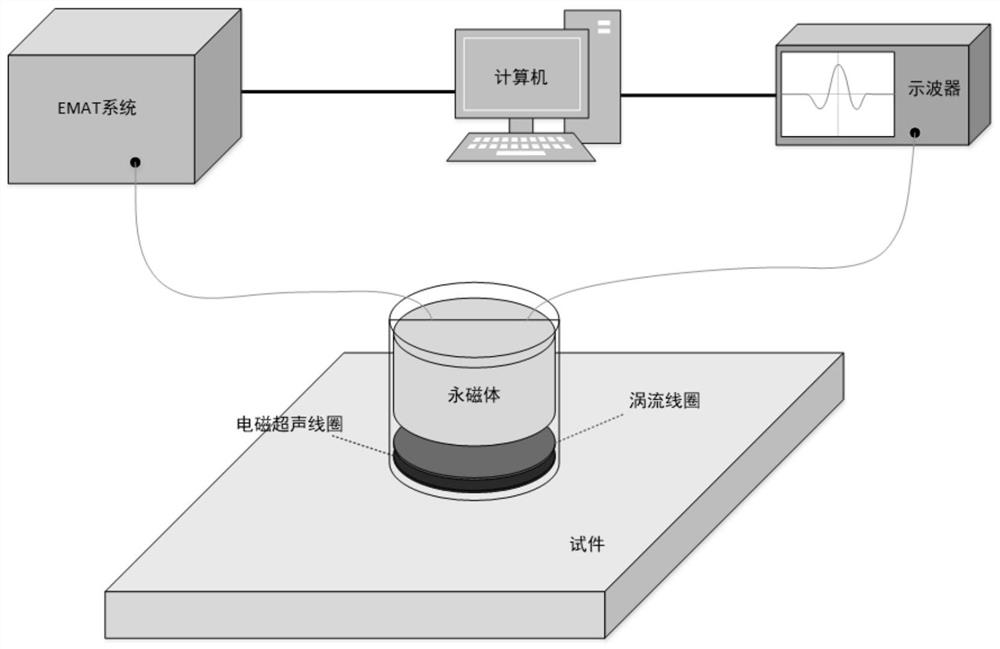

[0028] figure 1 It is a working principle diagram of an electromagnetic ultrasonic and pulsed eddy current composite detection sensor of the present invention.

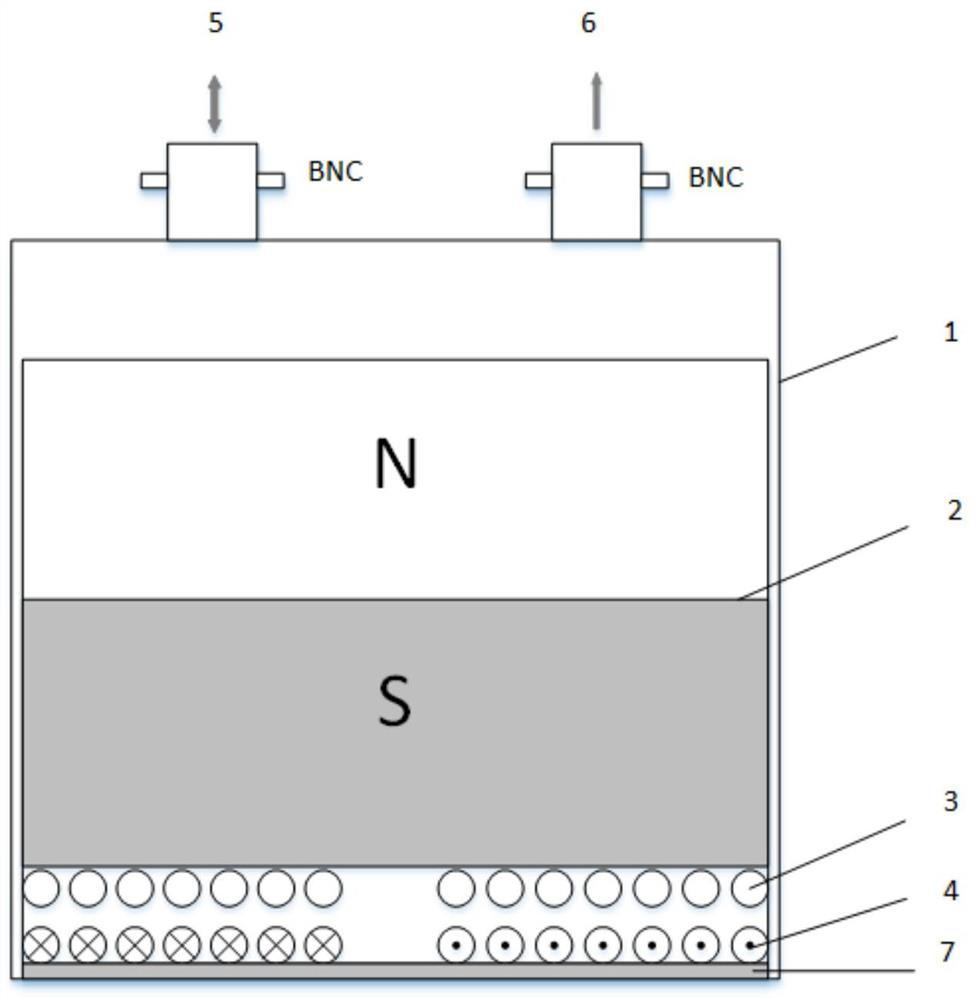

[0029] In this implementation case, if figure 2 As shown, an electromagnetic ultrasonic and pulsed eddy current composite detection sensor of the present invention includes: copper foil shielding layer 1, permanent magnet 2, pulsed eddy current coil 3, electromagnetic ultrasonic coil 4, pulsed eddy current BNC interface 5, electromagnetic ultrasonic BNC interface 6, Wear-resistant layer 7.

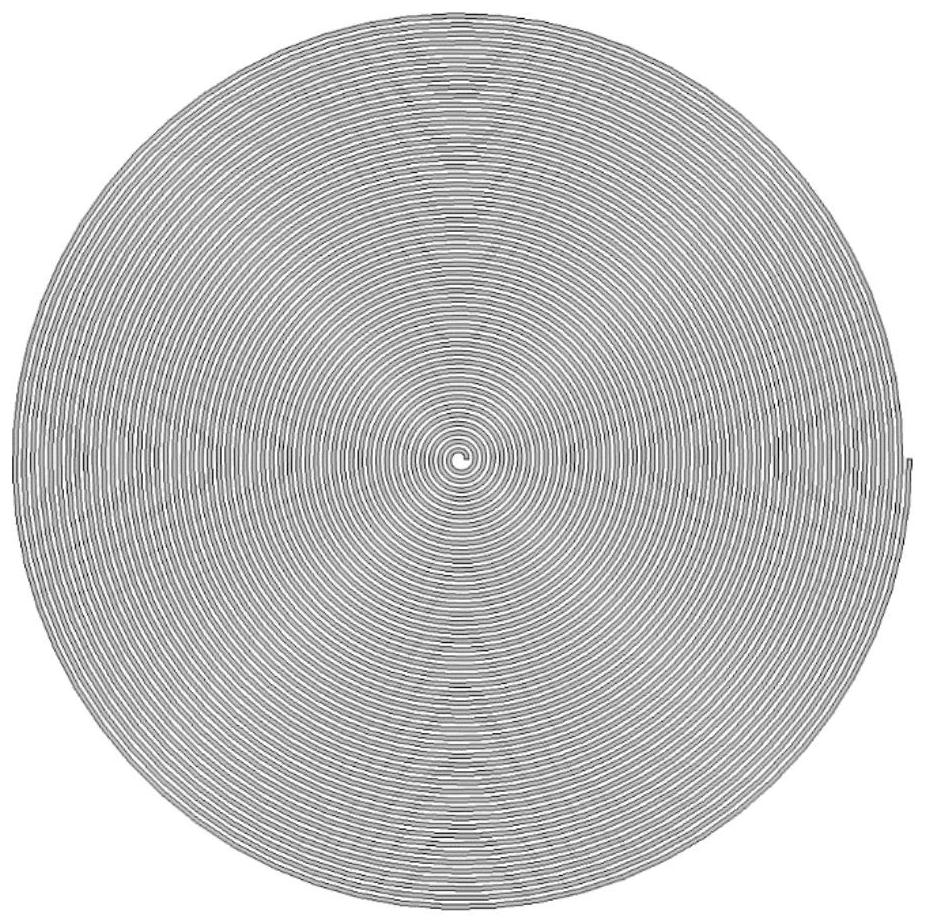

[0030] in, figure 2 main view, image 3 It is a plan view design diagram of the coil, and the sensor described in the present invention will be described in detail below in combination with these two diagrams.

[0031] The copper foil shielding layer 1 is a hollow cylinder with end caps on its upper surface, made of non-ferromagnetic materials such as copper foil, the difference between the inner and outer diameters is less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com