Measurement method of re-expansion rate of superabsorbent resin in simulated crack

A technology of super absorbent resin and measurement method, applied in cement concrete, super absorbent resin improves the field of concrete self-healing ability, can solve the problems of particle damage, complicated technical operation, long drying cycle, etc., and achieves easy operation and simple operation. , the effect of the simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

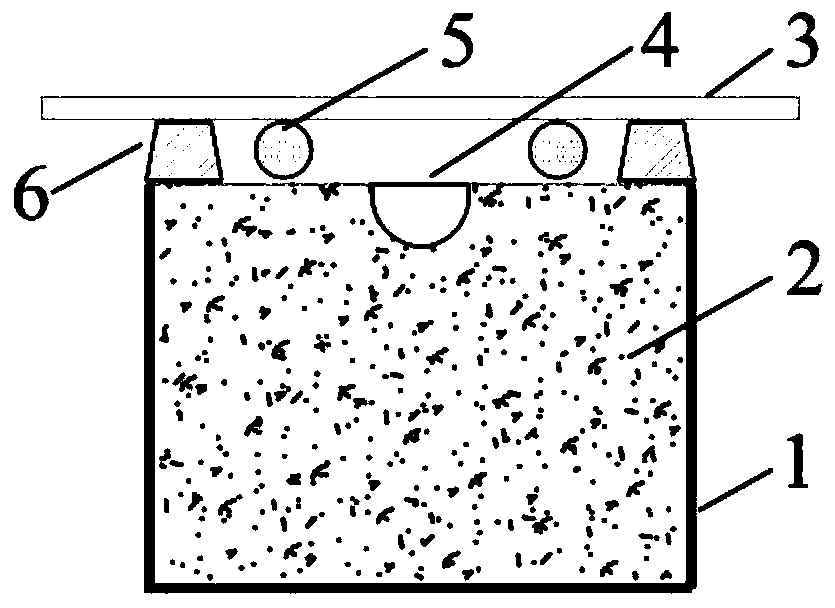

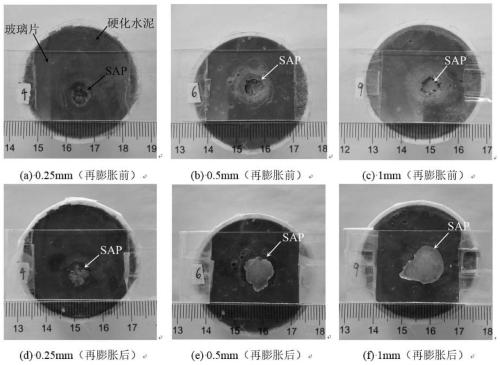

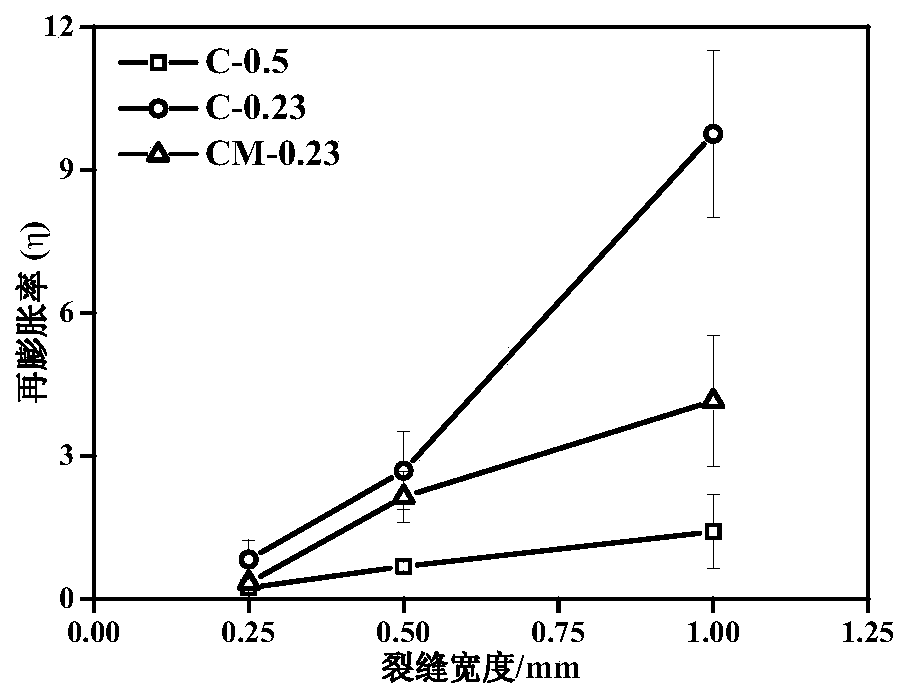

[0061] Schematic diagram of the measurement device for the re-expansion rate of superabsorbent resin in simulated cracks in hardened cement slurry as shown in figure 1 shown. The cement slurry 2 is poured on the surface of SAP 4 of known quality; after the cement slurry is hardened, a steel needle with a certain diameter is used to separate the glass sheet 3 from the hardened cement slurry, and a small amount of 502 glue 6 is injected around the sample. After the glue is hardened, take out the steel needle to obtain a simulated crack with a width of 0.25mm. Invert the sample and take it out after soaking in the solution for a certain period of time, absorb the solution in the crack with filter paper, and use a scale and a digital camera to obtain the area of the crack filled by SAP under the transparent glass sheet after re-expansion.

Embodiment 2

[0063] Schematic diagram of the measurement device for the re-expansion rate of superabsorbent resin in simulated cracks in hardened cement slurry as shown in figure 1 shown. The cement slurry 2 is poured on the surface of SAP 4 of known quality; after the cement slurry is hardened, a steel needle with a certain diameter is used to separate the glass sheet 3 from the hardened cement slurry, and a small amount of 502 glue 6 is injected around the sample. After the glue is hardened, take out the steel needle to obtain a simulated crack with a width of 0.5mm. Invert the sample and take it out after soaking in the solution for a certain period of time, absorb the solution in the crack with filter paper, and use a scale and a digital camera to obtain the area of the crack filled by SAP under the transparent glass sheet after re-expansion.

Embodiment 3

[0065] Schematic diagram of the measurement device for the re-expansion rate of superabsorbent resin in simulated cracks in hardened cement slurry as shown in figure 1 shown. The cement slurry 2 is poured on the surface of SAP 4 of known quality; after the cement slurry is hardened, a steel needle with a certain diameter is used to separate the glass sheet 3 from the hardened cement slurry, and a small amount of 502 glue 6 is injected around the sample. After the glue is hardened, take out the steel needle to obtain a simulated crack with a width of 1mm. Invert the sample and take it out after soaking in the solution for a certain period of time, absorb the solution in the crack with filter paper, and use a scale and a digital camera to obtain the area of the crack filled by SAP under the transparent glass sheet after re-expansion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com