A method for measuring the re-expansion rate of superabsorbent resin in hardened cement slurry

A technology of superabsorbent resin and measurement method, which is applied in the field of cement concrete, can solve the problems of complex technical operation, long drying cycle, and difficulty in repeated tests in large quantities, and achieve the effect of simple operation and simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

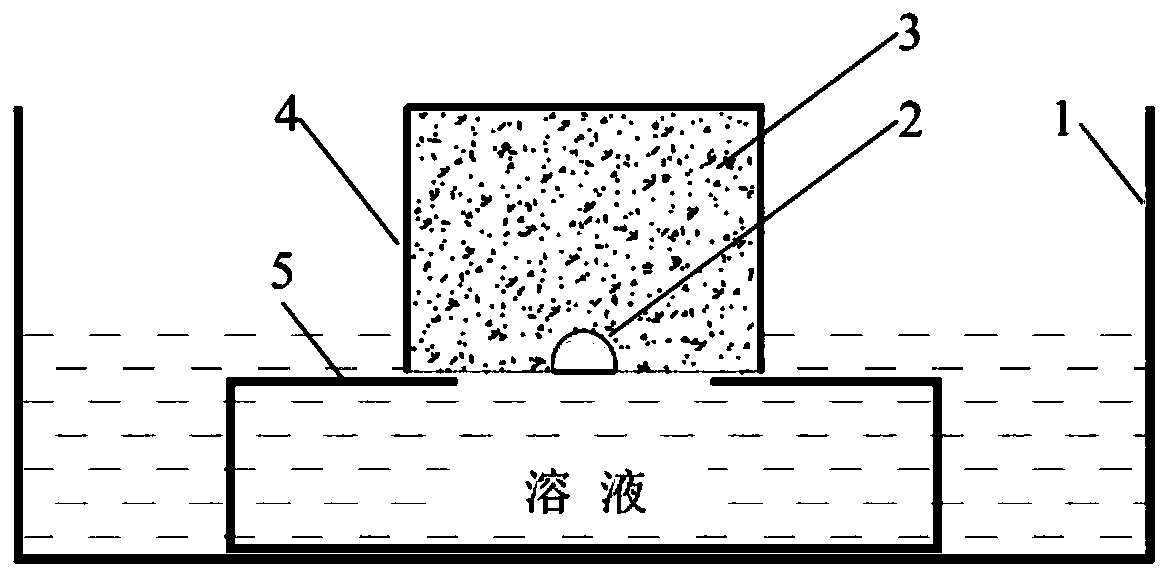

[0066] Example 1. Measuring device

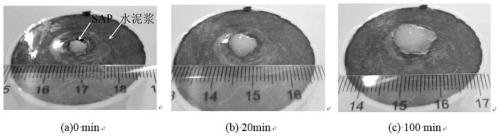

[0067] Schematic diagram of the measuring device for the reswelling ratio of superabsorbent resin in hardened cement slurry is shown in figure 1 shown. The cement slurry 3 was poured on the surface of SAP 2 of known quality; after the cement slurry hardened, the surface of the sample was sealed with adhesive tape, and only the SAP was exposed. The initial pores were filled with SAP by dropwise addition of deionized water, and the mass of the SAP-containing sample was subsequently weighed. Invert the weighed sample and take it out after soaking in the solution for a certain period of time, remove floating water on the surface of the sample with filter paper, and weigh the mass of the sample containing SAP again.

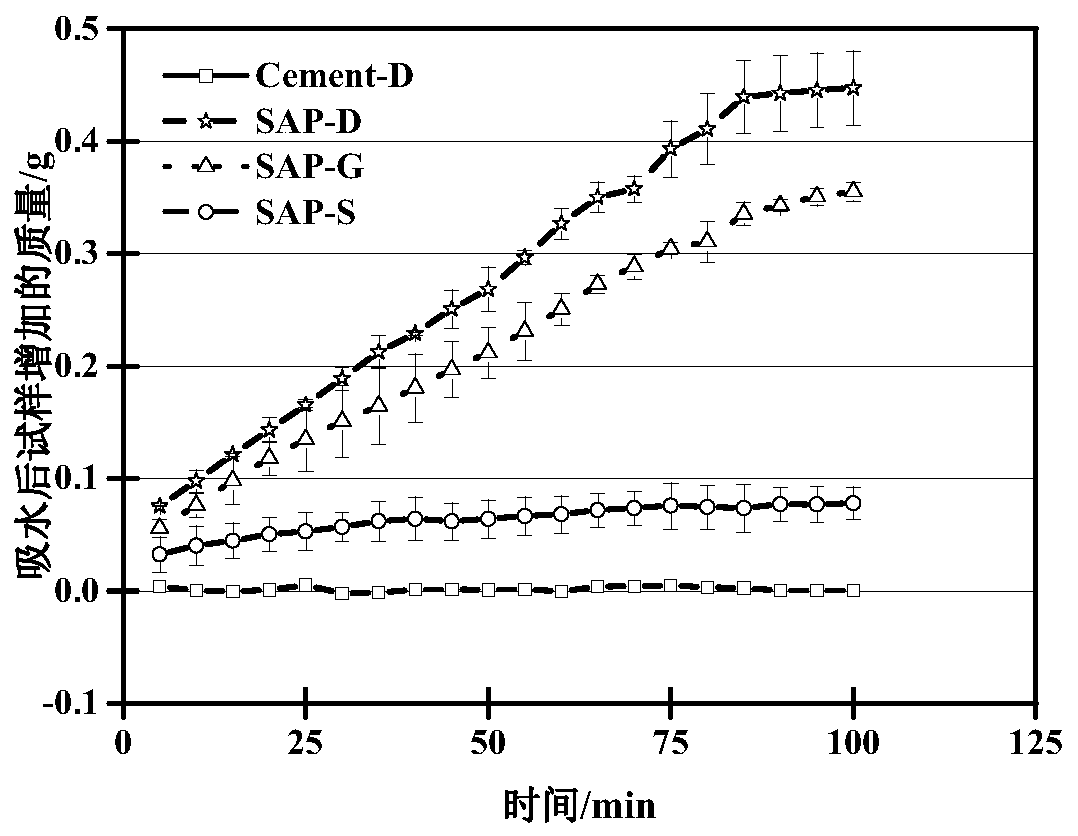

[0068] The increased mass of samples with and without SAP particles removed after absorbing water

[0069] The mix ratio of cement slurry is shown in Table 1. The test solution is deionized water, simulated groundwater and simu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com