High-voltage direct-current power source testing device of X-ray irradiator

A high-voltage DC power supply and testing device technology, which is applied in the field of X-ray irradiator manufacturing, can solve the problems of unmentioned test high-voltage DC power supply structure design, complex internal structure and principle, inconvenient joint debugging of the whole machine, etc., so as to achieve fast fault judgment. , The effect of easy to use in industrial field and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

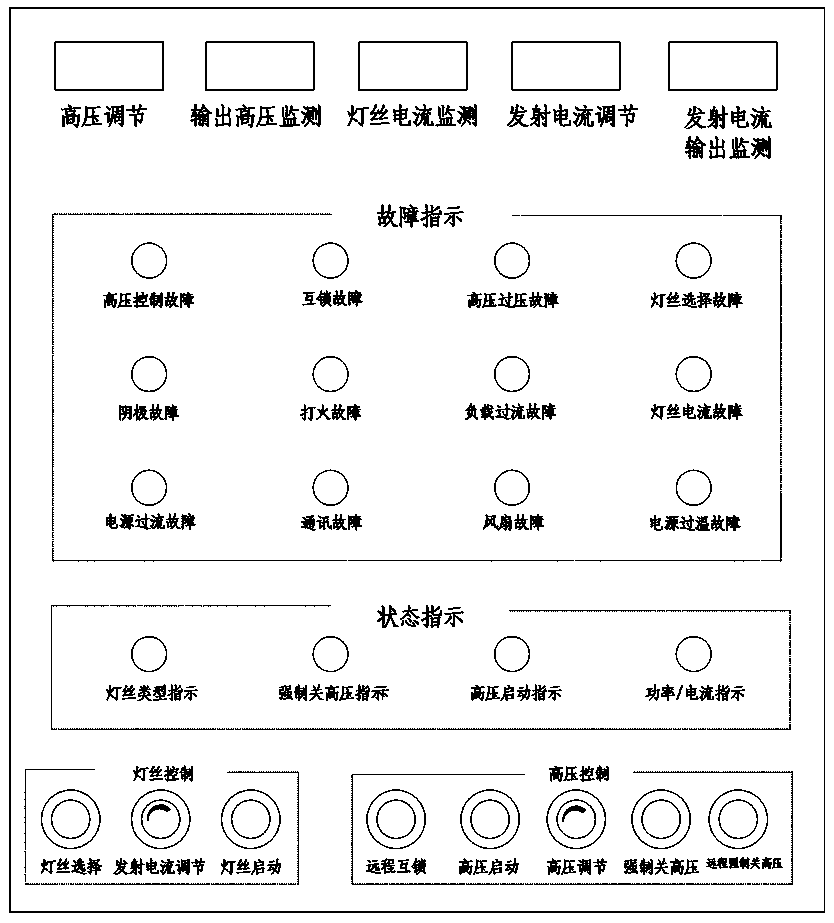

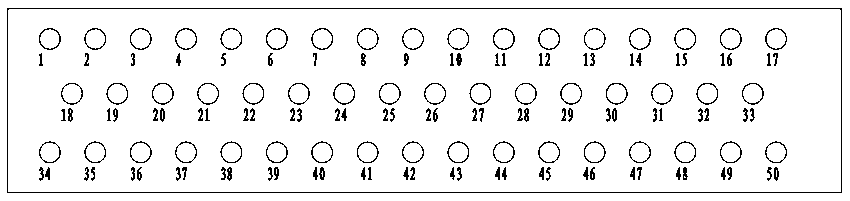

[0017] This embodiment provides an X-ray irradiator high-voltage DC power supply test device. The size of the case is 500*400*200. The operation panel is an upper cover with buckles, which can be opened. The male head of the DB50 interface terminal is fixed on the side of the X-ray irradiator through an external cable to connect the communication interface of the main control board of the high-voltage DC power supply of the X-ray irradiator. The main control board of the high-voltage DC power supply controls the start, stop, parameter adjustment, protection, etc. of the entire power supply. Function.

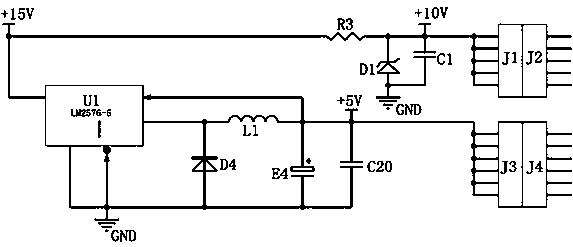

[0018] The 5 display heads are digital voltmeters, which are powered by 5V, the analog input range is 0-10V, and the display range is 0-20V; according to figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com