Simulation and analysis method of particle system based on composite hyperellipsoid model

A technology of simulation analysis and super ellipsoid, which is applied in the field of granular systems, can solve problems such as inaccurate simulation results, and achieve the effect of improving authenticity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

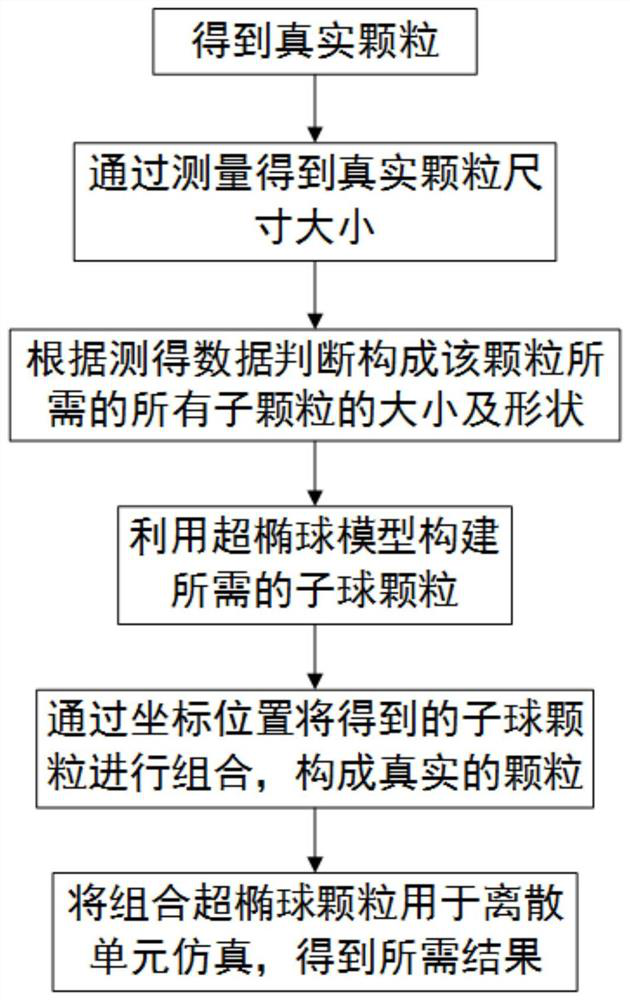

Method used

Image

Examples

Embodiment 1

[0056] The particles in the particle system are drug particles, and the shape is capsule particles.

[0057] (1) According to the size and shape of the real particle, determine the shape, size and number of the sub-hyperellipsoids that make up the particle.

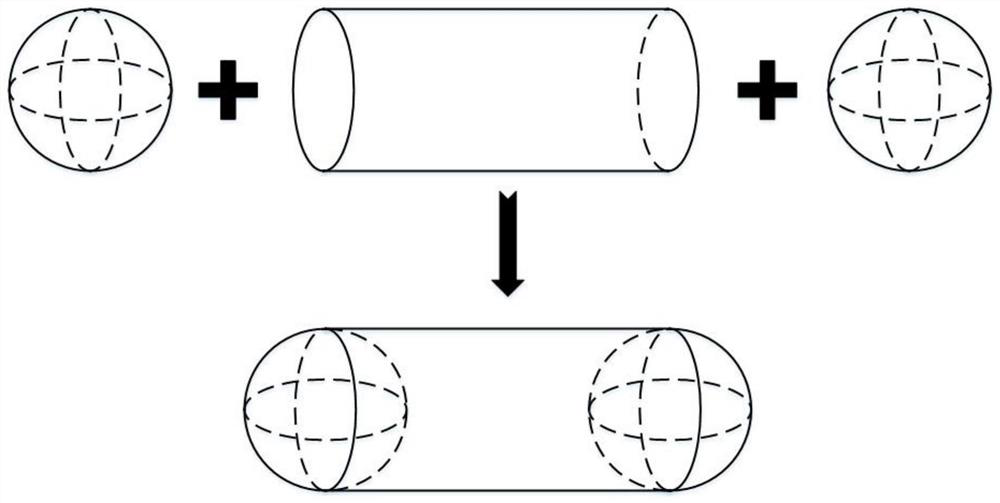

[0058] For real capsule-like particles, such as image 3 As shown, by measuring the size of real particles, the particle size data can be obtained. The total length is 12mm, and the diameter of the spheres on both sides is 4mm; It is two spheres and a cylindrical particle, the diameter of the sphere is 4mm, the diameter of the cylindrical particle is 4mm, and the height is 8mm.

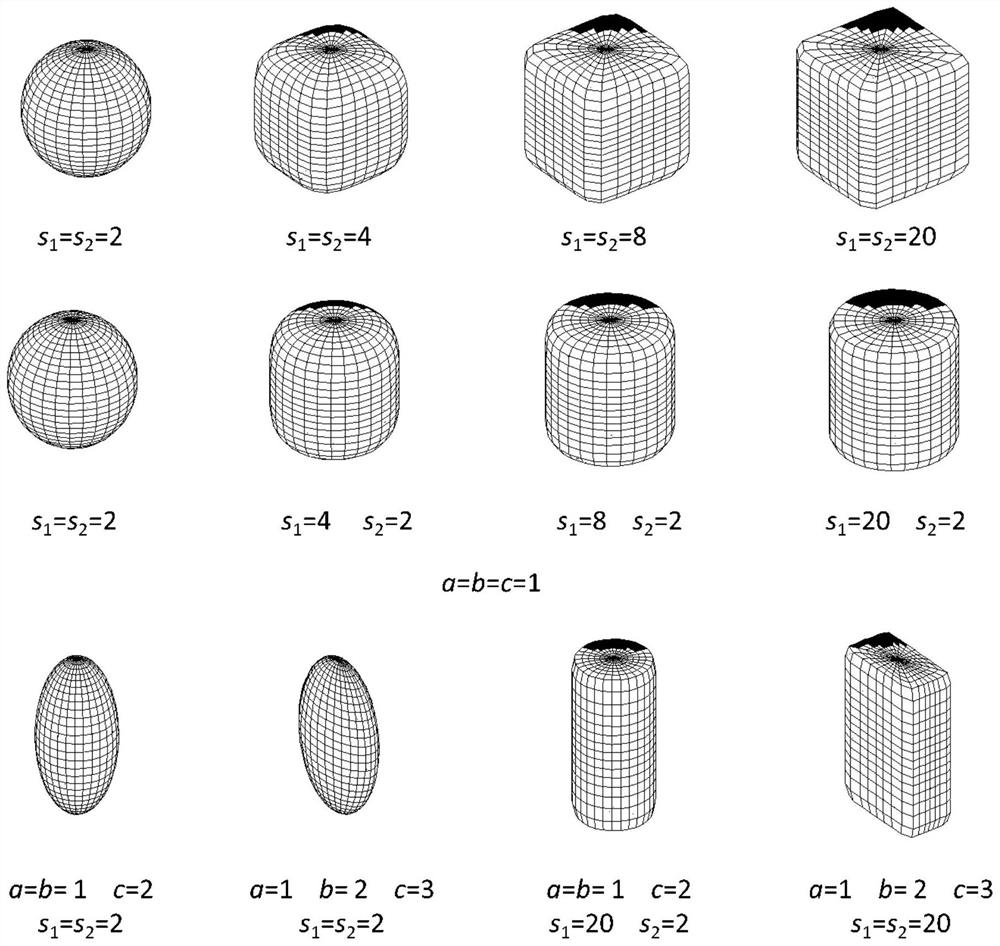

[0059] (2) Construct sub-hyperellipsoids through super-ellipsoid models, and then assign different coordinate positions to sub-hyperellipsoid particle models according to the size of real particles, and combine sub-hyperellipsoids to form a combined hyperellipsoid model of particles.

[0060] Build process like image 3 As shown, according to ...

Embodiment 2

[0065] Like the drug particles provided in Example 1, the drug particles in this embodiment are cylindrical particles that protrude on both sides.

[0066] Such as Figure 4 As shown, by measuring the size of the real particle, the size data of the particle can be obtained, the diameter is 8mm, the height is 4mm, and the height of the cylindrical section is 2mm; according to the measured data, all the required sub-hyperellipsoid particle models are constructed, What this particle requires are two ellipsoidal particles and one cylindrical particle. According to the hyperellipsoid model particle formula, for ellipsoidal particles, a=b=4, c=1, s 1 =s 2 =2, for cylindrical particles, a=b=4, c=1, s 1 =20,s 2 =2; combine all sub-hyperellipsoidal particles obtained, the center coordinates of cylindrical particles are (0,0,0), and the coordinates of two ellipsoidal particles are (0,0,1) and (0,0 ,-1), through the combination of three sub-hyperellipsoid particle models, the real cy...

Embodiment 3

[0070] As shown in Example 2, the drug particles in this example are elliptical cylindrical particles that protrude on both sides: as Figure 5 As shown, two ellipsoids plus one elliptic cylinder can be combined to form a kind of elliptical cylindrical particle with two sides protruding. The simulation results obtained by using the combined hyperellipsoid model are closer to the actual data than those obtained by using the combined sphere model.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com