A modeling and predicting method for instantaneous temperature characteristics of a multiphase pump cavity

A technology of instantaneous temperature and prediction method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of increasing the difficulty of parameter acquisition, complex time-varying characteristics, and increasing the difficulty of experimental design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

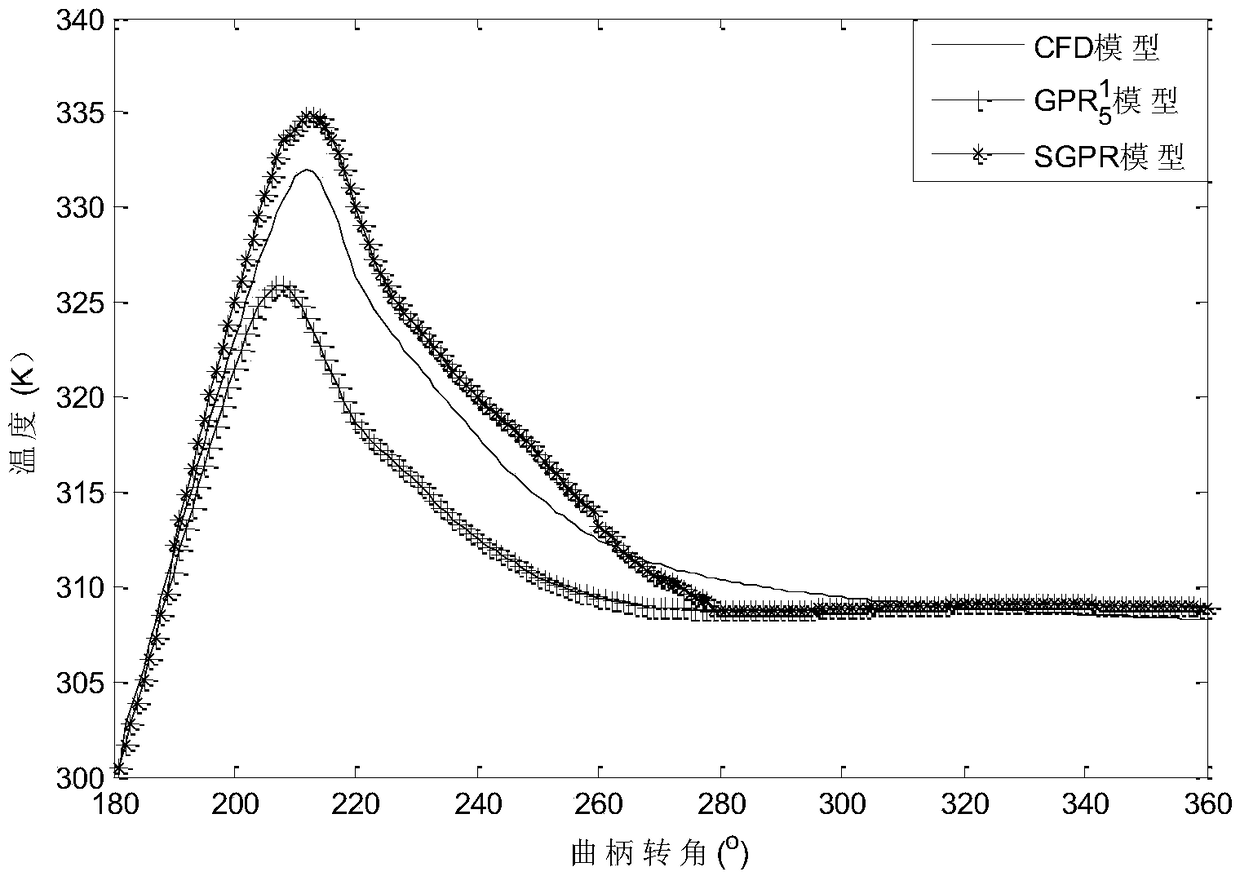

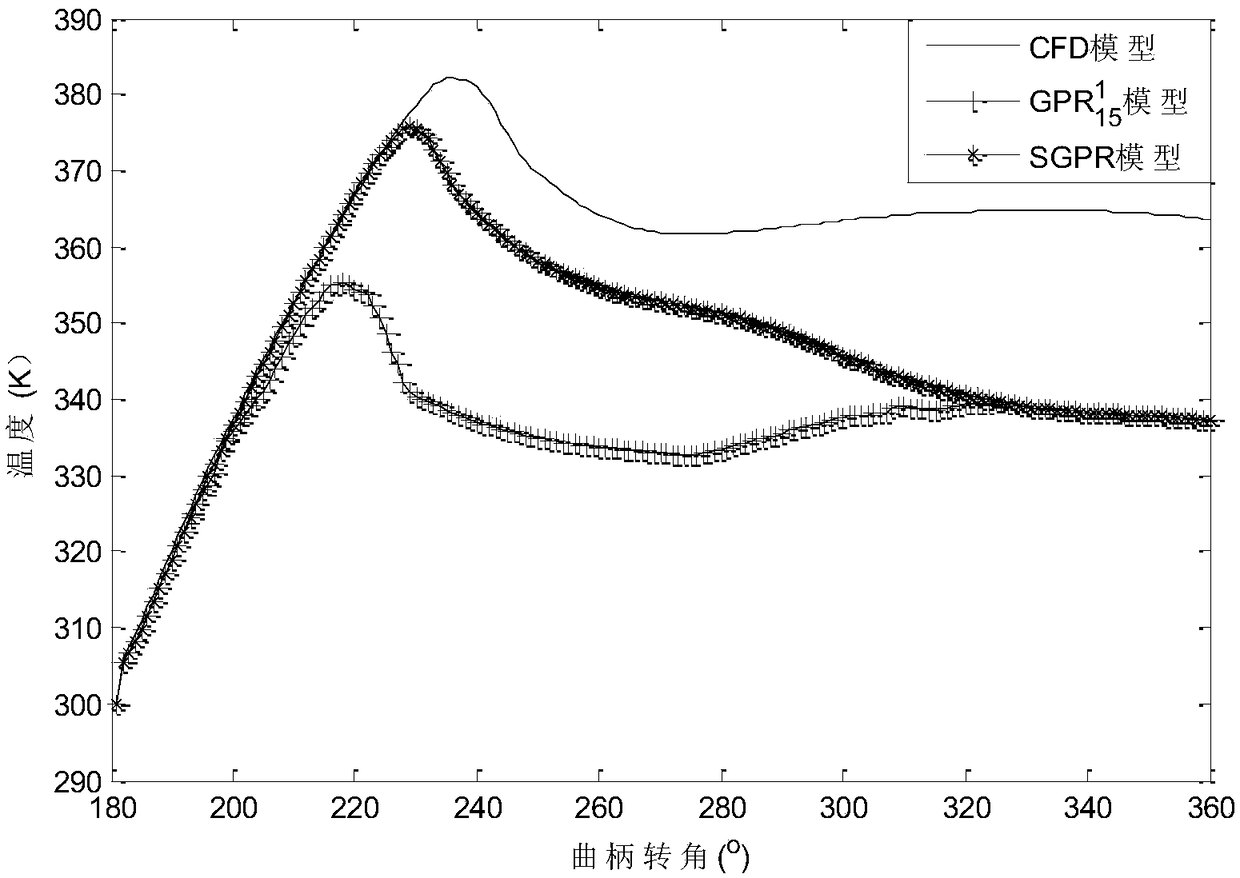

[0055] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description, taking a reciprocating mixed transport pump as the research object.

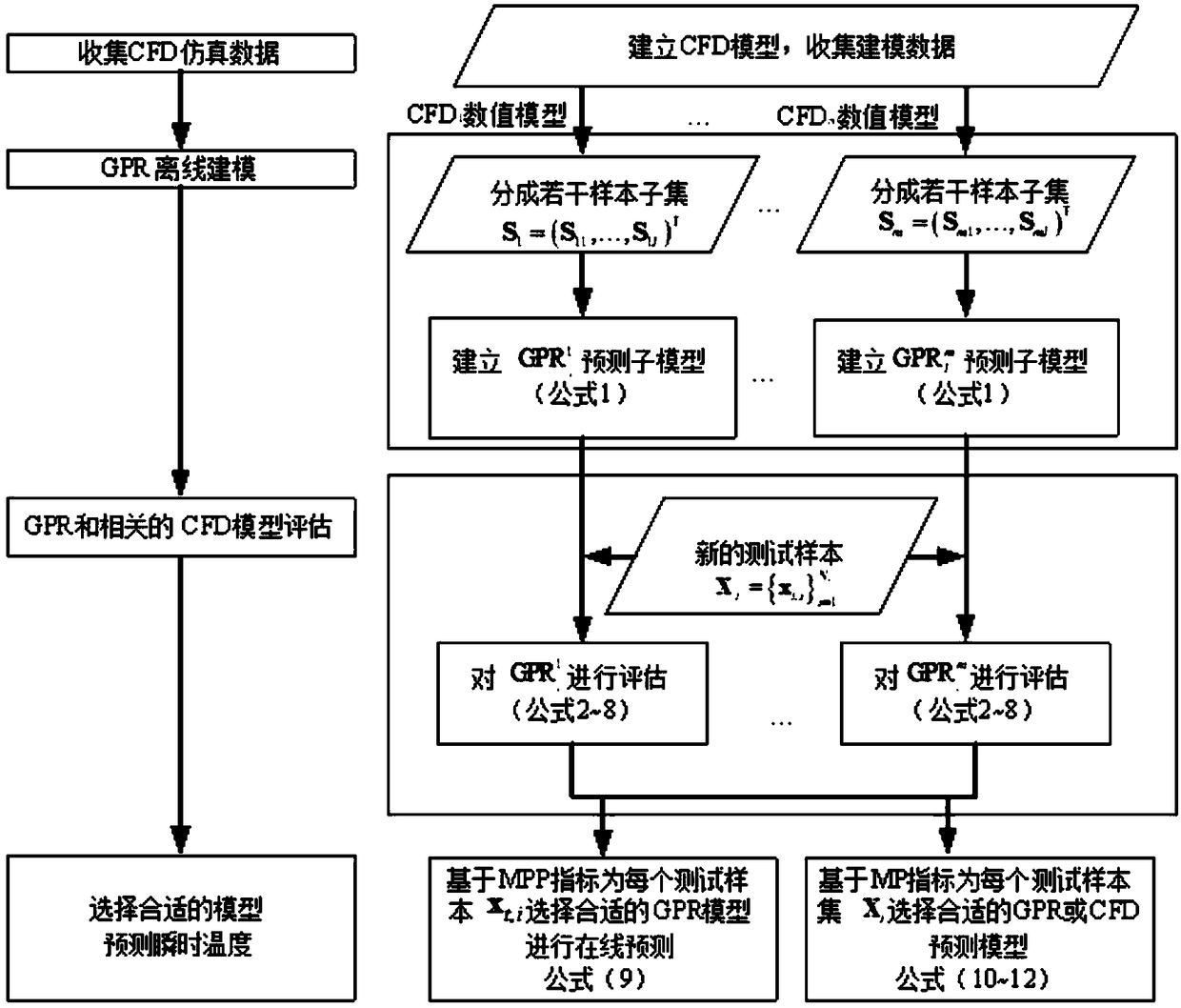

[0056] Such as Figures 1 to 4 As shown, a method for modeling and predicting the instantaneous temperature characteristics of a mixed pump cavity of the present invention includes the following steps:

[0057] 1) Select input and output variables for the CFD numerical model and the GPR empirical model.

[0058] The instantaneous temperature of the pump cavity of the reciprocating mixed transport pump is mainly affected by the air content rate, suction pressure, discharge pressure, rotational speed, crank angle, etc., and the temperature rise phenomenon of the pump cavity is especially obvious in the compression process when the air content rate is high. Therefore, comprehensively considering the operating conditions of the reciprocating mixed transport pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com