Wax removal system of full-automatic amorphous process

An amorphous and waxing technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high cost, long time, serious pollution, etc., and achieve the effect of improving waxing efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

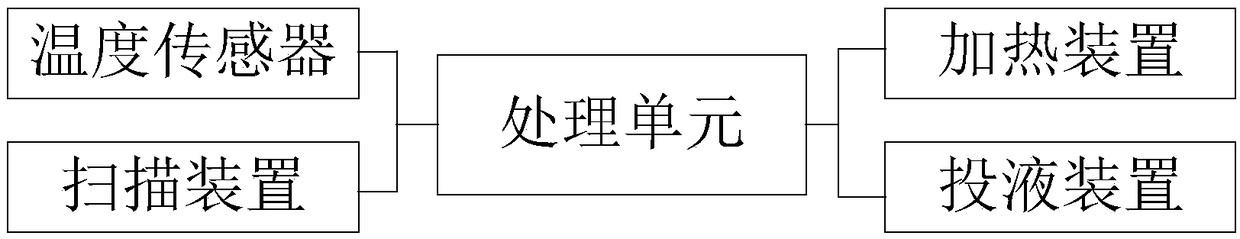

[0021] figure 1 It is a functional block diagram of the waxing system of the present invention;

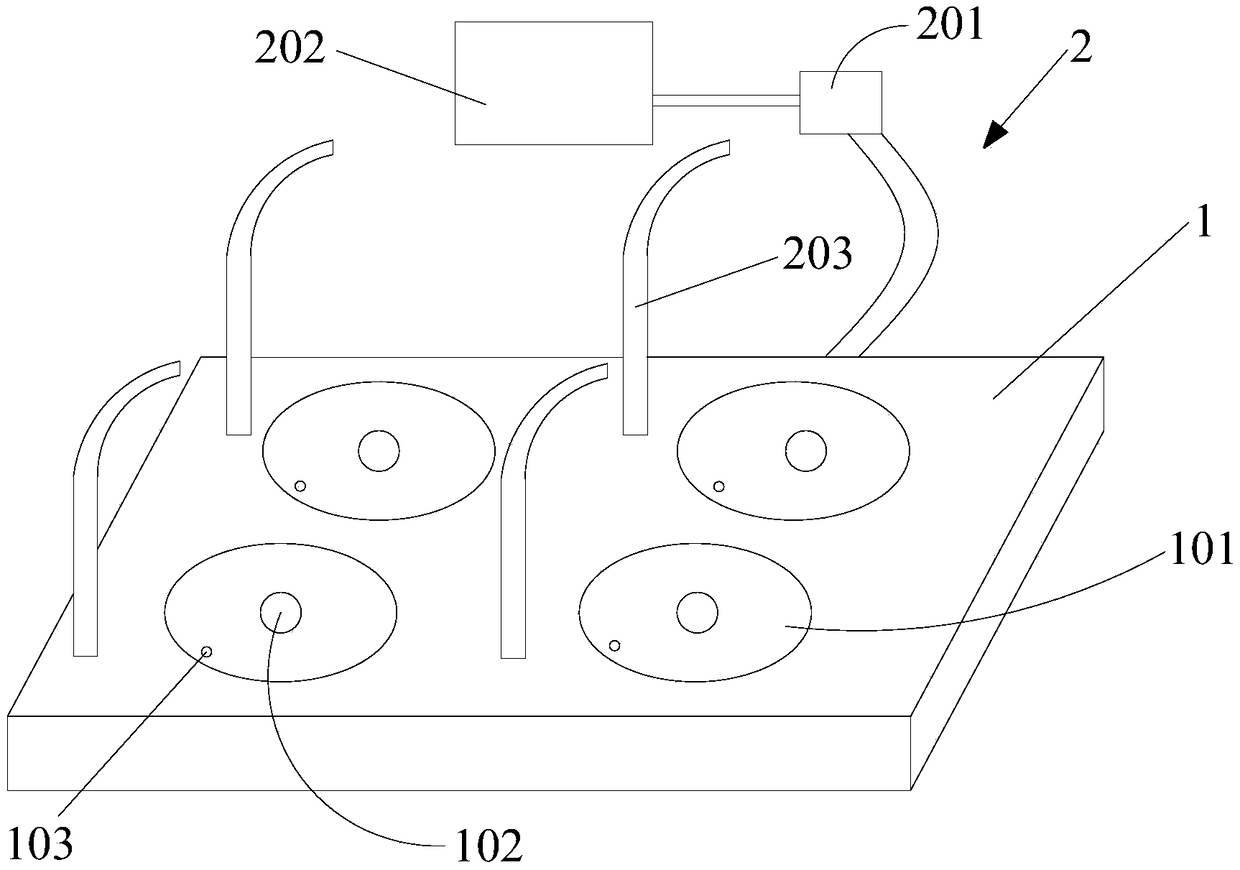

[0022] figure 2 It is a structural diagram of the wax removal system of the present invention.

[0023] In this example, if figure 1 , figure 2 As shown, the present embodiment provides a fully automatic amorphous process wax removal system, which includes: a processing unit, a heating device 1, and a liquid injection device 2; wherein the heating device 1 is provided with several heating tanks 101, the The heating tank 101 is suitable for placing a non-wafer ceramic disc with wax stickers; Spray down the wax to release the non-wafer from the ceramic plate.

[0024] In this embodiment, the present invention realizes the function of automatic control of waxing, overcomes the traditional problem of manual handling and manual removal of wax stickers and non-wafers, saves manpower and material resources, and improves waxing efficiency.

[0025] In order to control heating, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com