Method for preparing ruminant feed from edible mushroom dregs as raw material

A technology of ruminants and fungus residue, which is applied in the field of resource utilization of agricultural product processing waste, can solve the problems of high dry matter loss of raw materials and low economic performance, and achieve the goals of accelerating lactic acid accumulation, improving processing capacity, and avoiding secondary fermentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

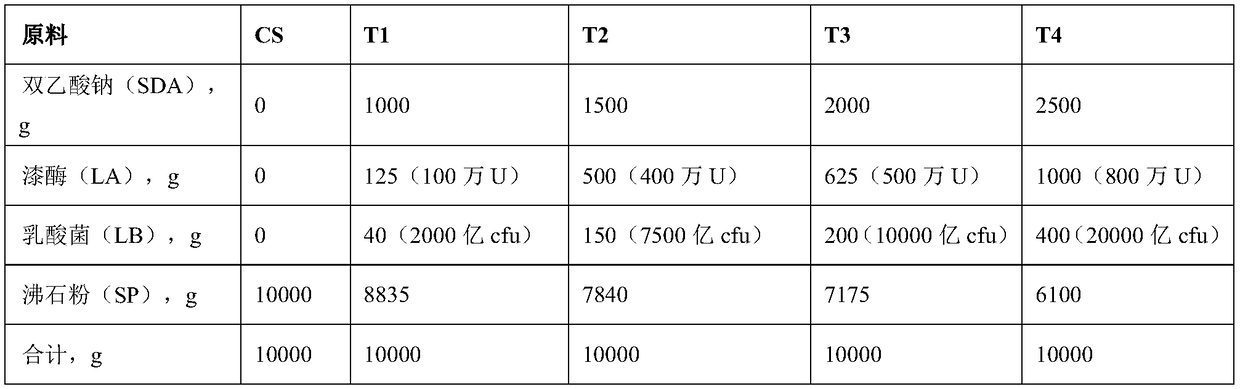

[0025] (1) Preparation of fermentation additives. According to different amounts of raw materials, four kinds of additives are produced, T1, T2, T3, T4. The raw material composition of every 10kg additive is shown in Table 1.

[0026] Table 1 Different formulations of silage additives g

[0027]

[0028] (2) For each treatment group, use 30 tons of fungus residue, add 300kg of corresponding fermentation additives, mix evenly, and put it into a fermentation cellar with length, width and height of 4m×4m×3m at one time, and compact and airtight deal with. Another control group (CS) was set up, and the fermentation additive was replaced by 300kg zeolite powder. The specifications of the above five fermentation cellars are the same, the environmental conditions are basically the same, and the total mass of the fungus residues filled is basically the same. The results of the determination of the main components of the fungus residue showed that the DM content was 54.7%; calcu...

Embodiment 2

[0039] (1) Preparation of fermentation additives. The formula per 10 kg is 2000 g of sodium diacetate, 625 g of laccase (5 million U), 200 g of lactic acid bacteria (1 trillion cfu), and the remaining mass is carrier zeolite powder.

[0040](2) Set up two treatment groups, namely the seafood mushroom residue and the Pleurotus pleurotus mushroom residue treatment group. The dosage of the two treatment fermentation additives is the same as adding 10kg for every 1000kg of bacteria residue. The fermentation cellar, filling capacity, fermentation process, sample collection and testing are the same as in Example 1.

[0041] (3) Result analysis. The two kinds of fungus residues were fermented for 30 days, and the main components of the products are shown in Table 3. In this example, there is a big difference in indicators such as crude fiber, lignin, and crude protein between seafood mushroom and Pleurotus eryngii mushroom residue. Pleurotus eryngii slag fiber material is 20% hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap