Pavement brick cutting device with supporting mechanism

A technology of supporting mechanism and pavement bricks, which is applied in the direction of manufacturing tools, grinding workpiece brackets, grinding machines, etc., can solve the problems affecting the processing effect of brick workpieces, unsightly, uneven brick workpieces, etc., and achieve improved stability and good support effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

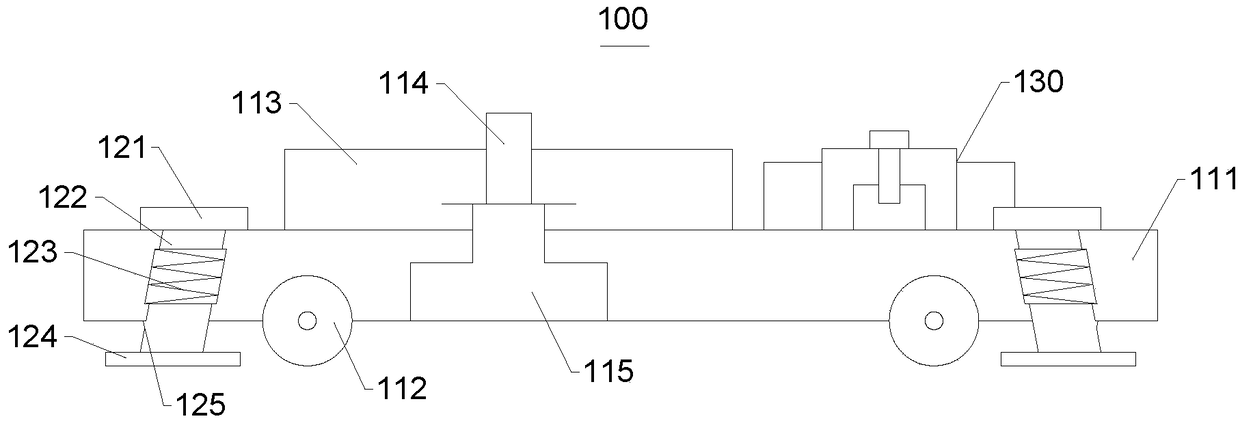

[0021] Please refer to figure 1 , the present embodiment provides a device for cutting pavement bricks 100 with a support mechanism, which includes a device, a grinding assembly, a support assembly 120 and a clamping assembly 130, the support assembly 120 is connected to the bottom of the device, and it plays a role of support, clamp The component 130 is arranged on the top of the device, which plays the role of clamping the paving bricks. The grinding component is connected to the top of the device and has a gap with the clamping component 130, which is used for grinding the paving bricks; the device includes a device body 111 And wheel 112, grinding assembly includes grinding disc 113, wheel shaft 114 and driver 115, and support assembly 120 includes pressing plate 121, support bar 122, spring body 123 and support plate 124, and clamping assembly 130 includes fixed block, telescopic sheet, clamping boards and spacers.

[0022] The device includes a device body 111 and wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com