Integrated design method for forward-sweep internal wave-multiplying inlet based on conical precursor shock waves

A design method and air intake technology, applied to aircraft parts, ground devices, fuselage, etc., can solve problems such as mismatching, achieve good matching, improve starting performance, and good lift-drag characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

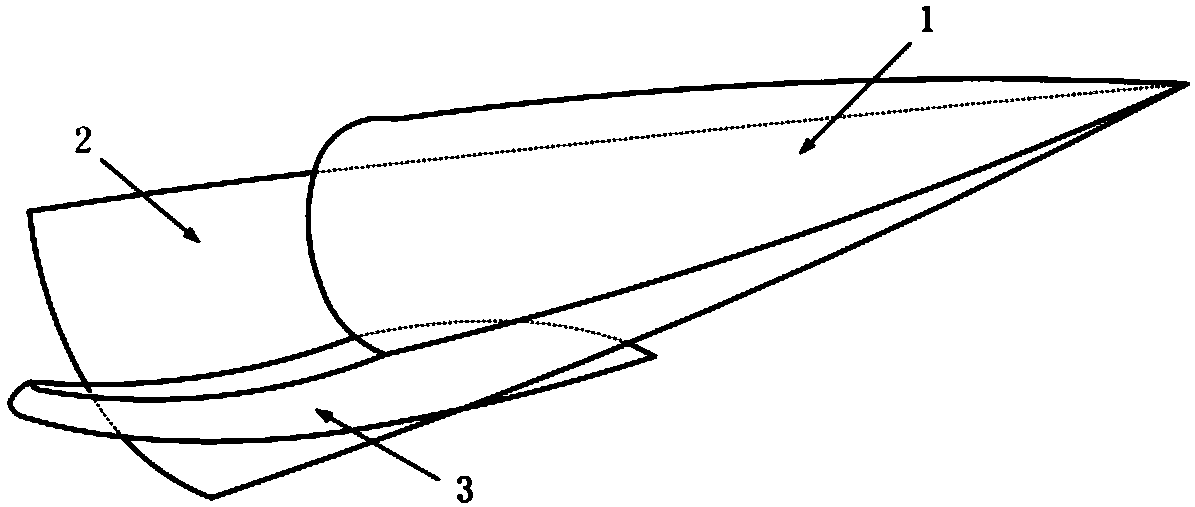

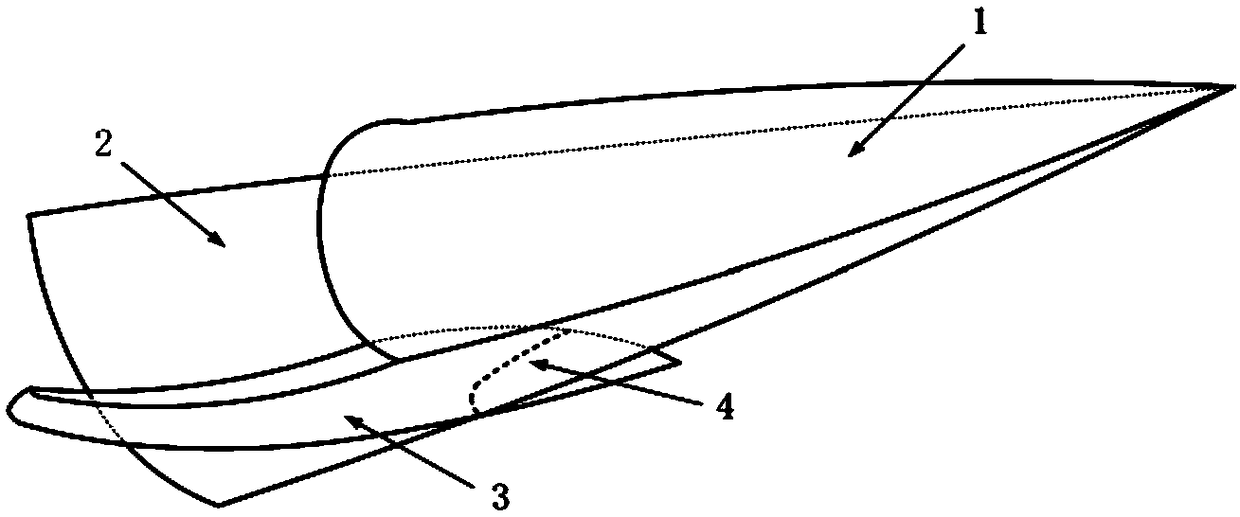

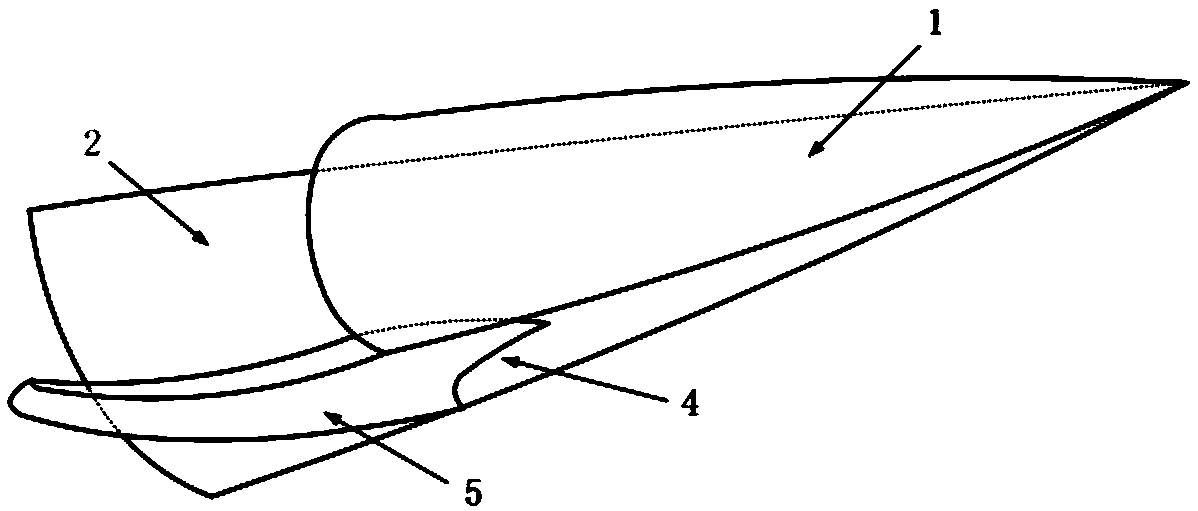

[0027] like image 3 As shown, the integrated design method of the forward-swept inner waverider inlet based on the shock wave of the conical precursor of the present invention is provided with the conical precursor 1 and the compression profile 5 of the forward-swept inner waverider inlet; the forward-swept inner waverider inlet The airway compression profile 5 is installed on the rear and lower part of the conical precursor 1 via the three-dimensional inward contraction airway profile, and the three-dimensional inward contraction airway profile 3 is cut using the three-dimensional conical shock wave surface 2 obtained by surface fitting, and the It is obtained after protruding the part of the three-dimensional conic shock surface 2. The forward-swept inner waverider inlet is composed of the forward-swept inner waverider inlet compression profile 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com