Buried oil tank lining transformation technology

An oil tank and lining technology, which is applied in the field of buried oil tank lining transformation technology, can solve the problems of easy corrosion of oil tanks, long shutdown time, troublesome installation, etc., and achieve improved mechanical properties, reduced input costs, reliable anti- seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

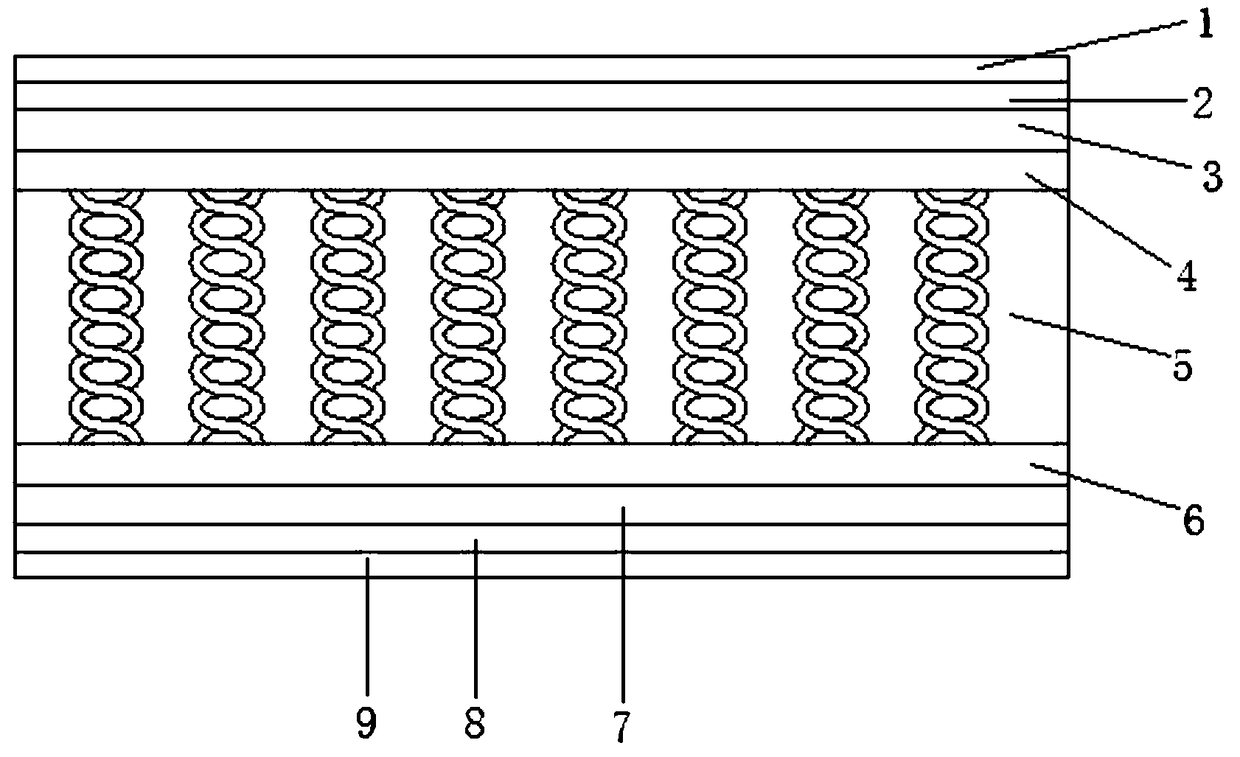

[0033] like figure 1 As shown, the present invention comprises oil tank inner wall 1, and oil tank inner wall 11 is provided with liner, and described inner liner is successively made of primer layer 2, first anti-leakage layer 3, first structure layer 4, hollow layer from inside to outside. Layer 5, second structural layer 6, second anti-leakage layer 7, third structural layer 8, and antistatic layer 9 are compounded.

[0034] The process of rebuilding the lining of buried oil tanks includes the following steps:

[0035] a. Cleaning and derusting the inner wall of the oil tank 1: Use a high-pressure cleaner for sandblasting cleaning, and the derusting grade is Sa2.5;

[0036] b. Drying: Drain the accumulated water and sand in the oil tank, and use a heating fan to heat and dry the oil tank; in actual operation, the concentration of oil and gas in the tank after cleaning the tank should be lower than the lower limit of the explosion limit (gasoline explosion limit 1.0%~ 6%, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap