Cellulose nanofiber hydrogel and preparation method thereof

A nanofiber and cellulose technology, applied in fiber treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of high cost, limited adsorption performance of visible light catalyst, complicated operation, etc., and achieve low cost, easy promotion, The effect of simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

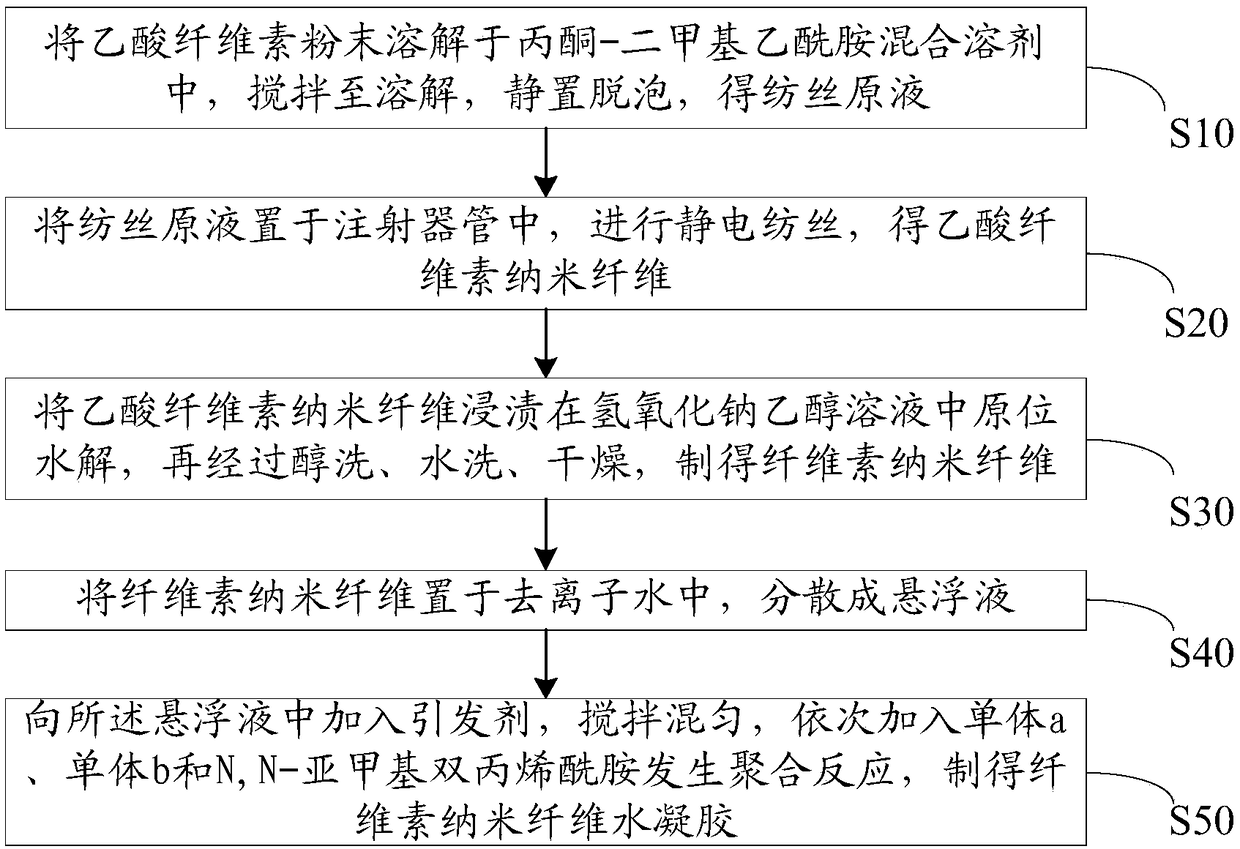

[0040] The present invention also proposes a preparation method of cellulose nanofiber hydrogel, combining figure 1 The schematic flow chart of the preparation method of the shown cellulose nanofiber hydrogel, the preparation method of the cellulose nanofiber hydrogel comprises the following steps:

[0041] S40, placing the cellulose nanofibers in deionized water, and dispersing them into a suspension.

[0042] S50, adding an initiator to the suspension, stirring and mixing, sequentially adding monomer a, monomer b and N,N-methylenebisacrylamide to undergo a polymerization reaction to prepare a cellulose nanofiber hydrogel.

[0043]Wherein, monomer a is at least one of acrylic acid and its alkali metal salts, ammonium salts and organic amine salts, and methacrylic acid and its alkali metal salts, ammonium salts and organic amine salts;

[0044] Monomer b is one or both of acrylamide and methacrylamide.

[0045] Wherein, the initiator is persulfate or peroxide, and the added ...

Embodiment 1

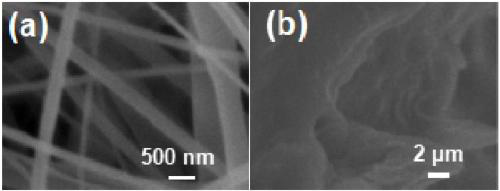

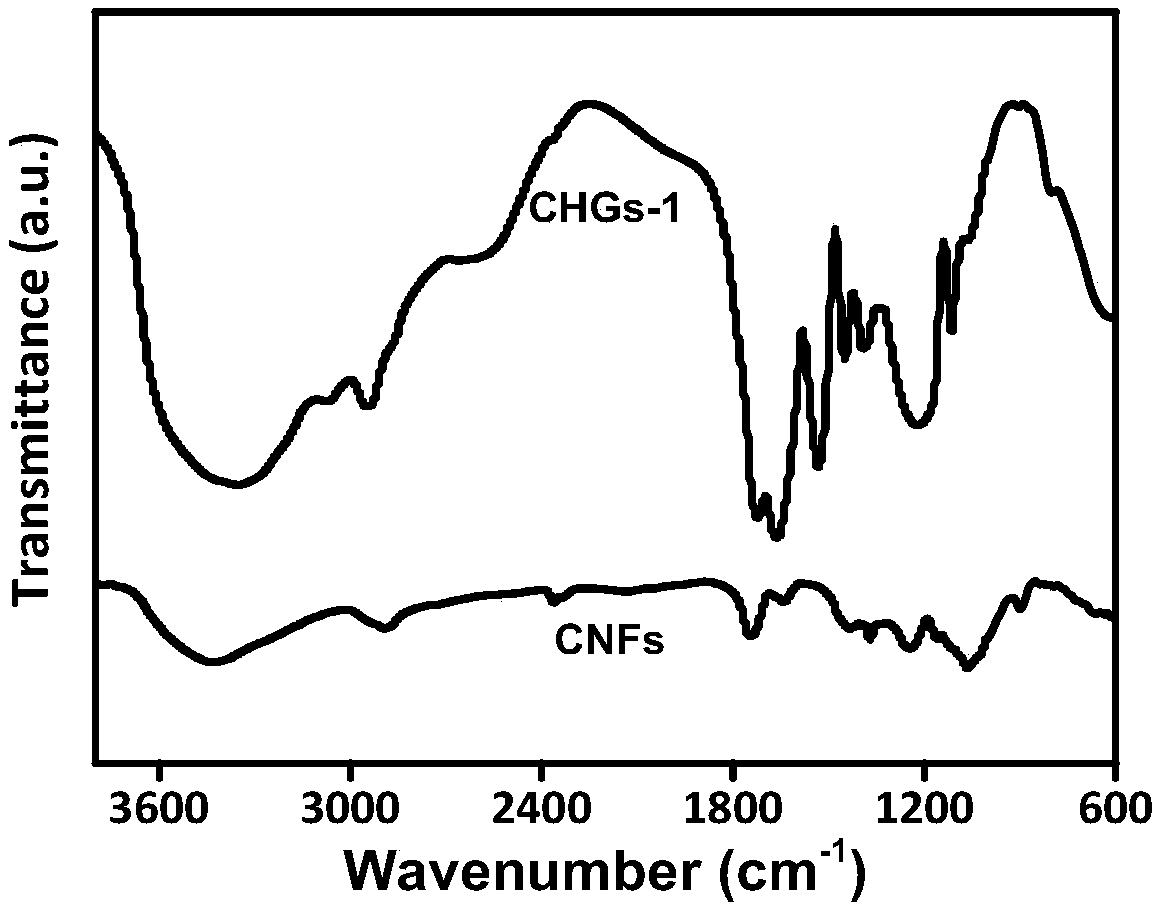

[0064] First weigh 0.8g of cellulose acetate powder in 5ml of acetone-dimethylacetamide (2:1, v:v) mixed solvent, stir magnetically in a screw-top vial for 1.5h until dissolved, and prepare after standing still for defoaming Form a uniform spinning stock solution; put the stock solution into a 5ml medical syringe tube (the diameter of the injection needle is 0.6mm), and use electrospinning technology at a working voltage of 20KV, a solution flow rate of 1ml / h, and a distance from the needle tip to the drum of 15cm Spinning under certain conditions to prepare cellulose acetate nanofibers; immerse cellulose acetate nanofibers in sodium hydroxide ethanol solution for 24 hours to promote in-situ hydrolysis and reduction of cellulose acetate components in nanofibers to cellulose. After the reaction After washing with alcohol, washing with water and drying, the cellulose nanofibers are obtained. Weigh 1 g of cellulose nanofibers and place them in deionized water, fully swell and dis...

Embodiment 2

[0070] First weigh 0.8g of cellulose acetate powder in 5ml of acetone-dimethylacetamide (2:1, v:v) mixed solvent, stir magnetically in a screw-top vial for 1.5h until dissolved, and prepare after standing still for defoaming Form a uniform spinning stock solution; put the stock solution into a 5ml medical syringe tube (the diameter of the injection needle is 0.6mm), and use electrospinning technology at a working voltage of 20KV, a solution flow rate of 1ml / h, and a distance from the needle tip to the drum of 15cm Spinning under certain conditions to prepare cellulose acetate nanofibers; immerse cellulose acetate nanofibers in sodium hydroxide ethanol solution for 24 hours to promote in-situ hydrolysis and reduction of cellulose acetate components in nanofibers to cellulose. After the reaction After washing with alcohol, washing with water and drying, the cellulose nanofibers are obtained. Weigh 1 g of cellulose nanofibers and place them in deionized water, fully swell and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap