High-pressure air flow control valve

A technology of flow control and high-pressure air, applied in the direction of valve lift, valve details, engine components, etc., can solve the problems of non-command shutdown failure, complex control structure, narrow application range, etc., to achieve high reliability and accuracy, wide The effect of pressure application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

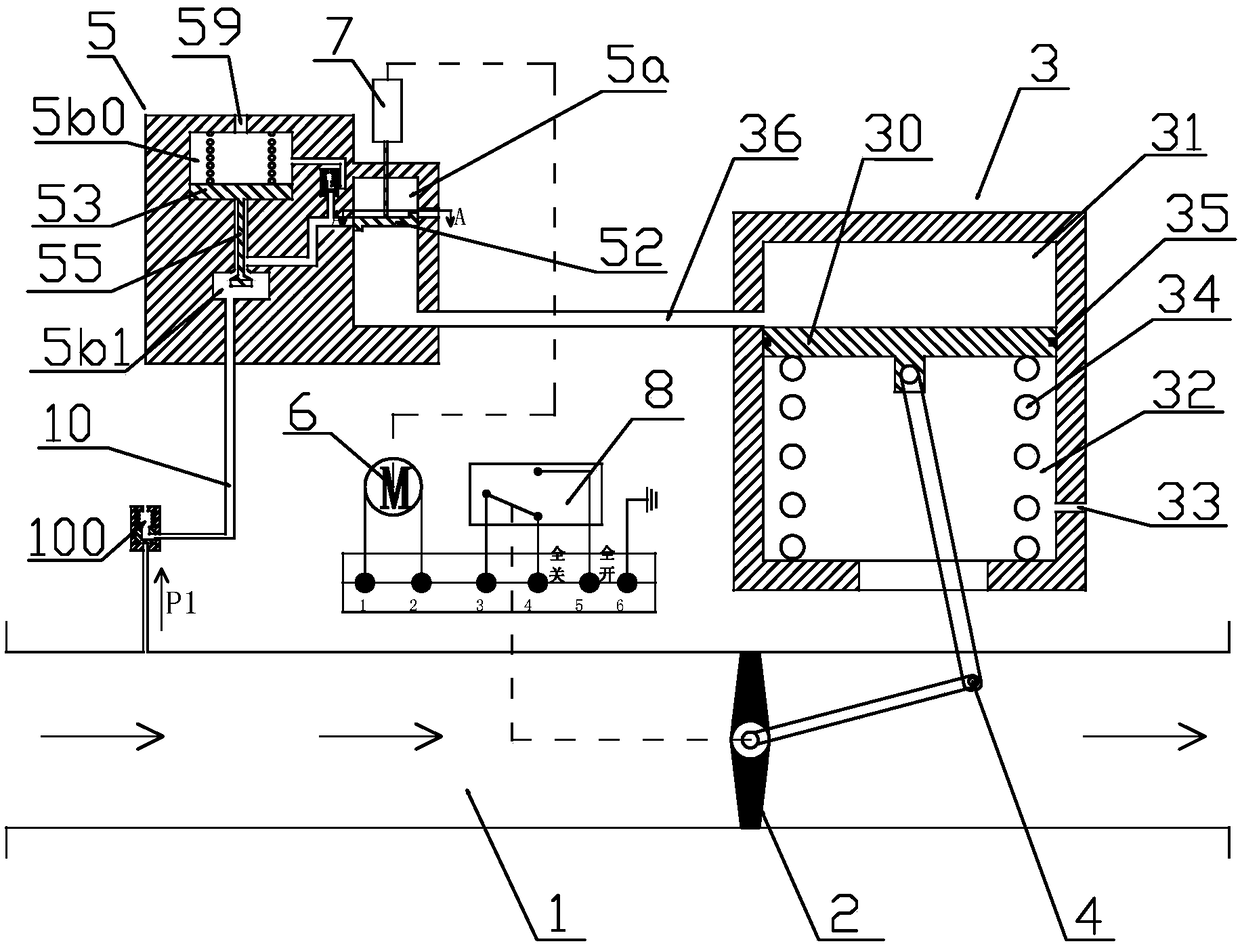

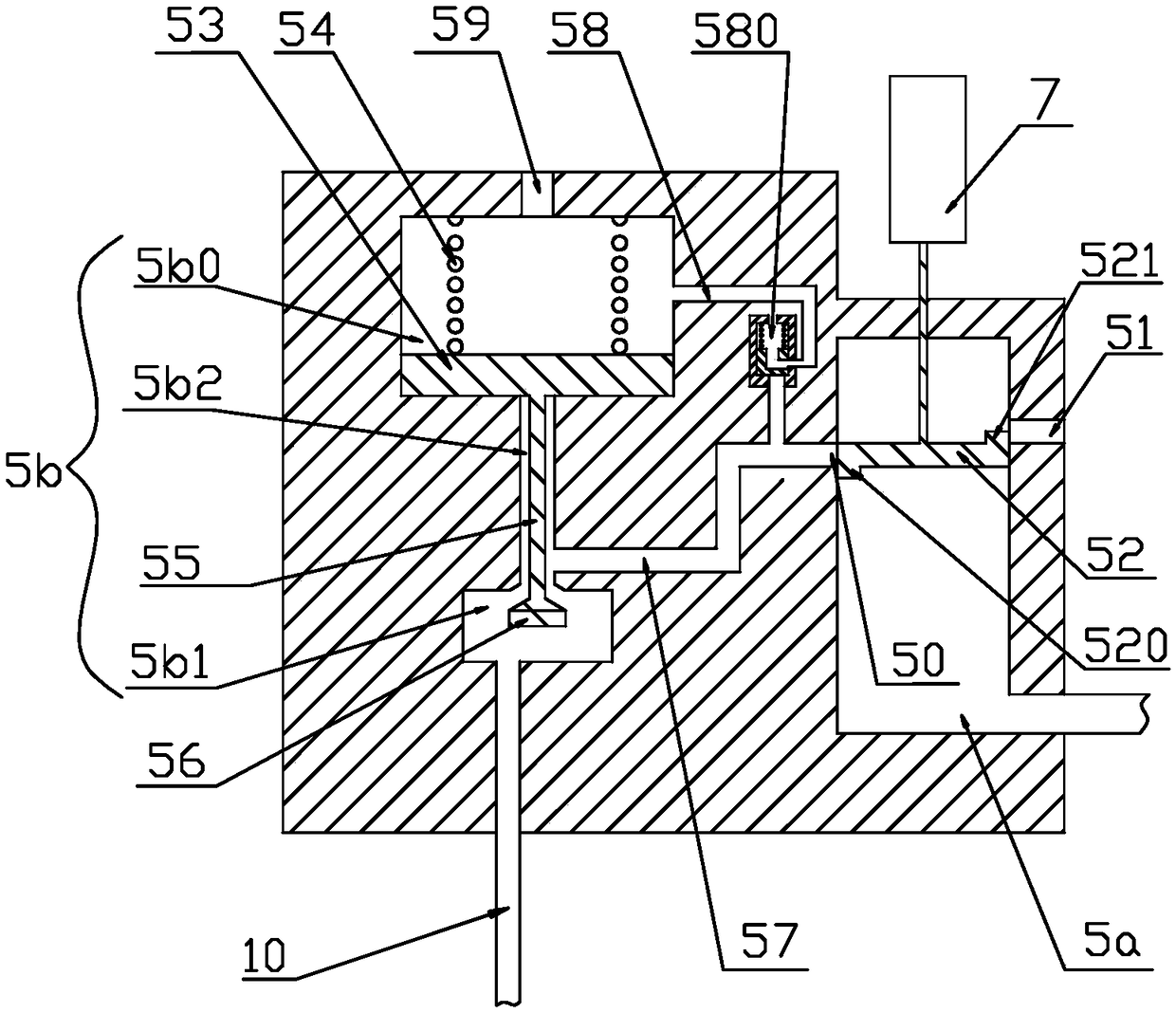

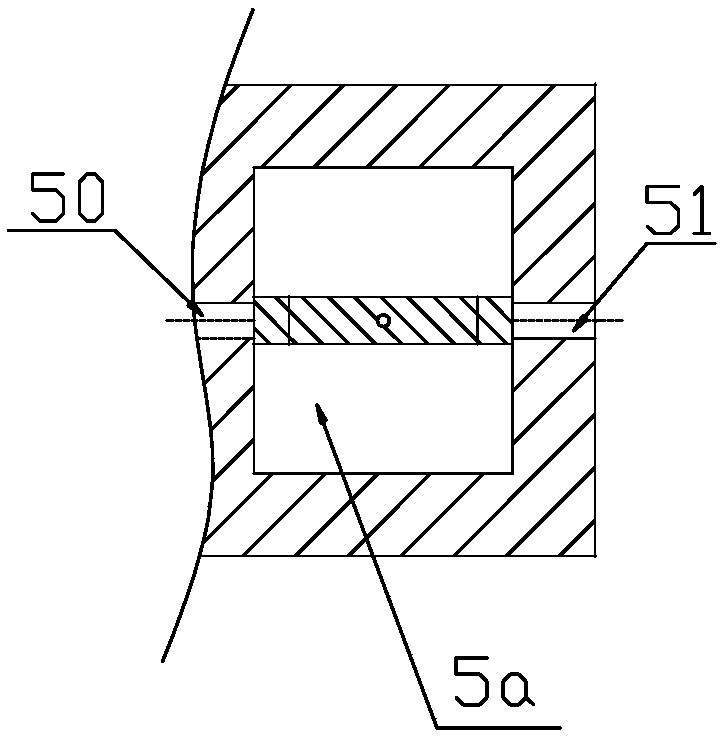

[0030] refer to Figure 1 to Figure 3 The high-pressure air flow control valve shown mainly includes a pneumatic actuator 3, a pressure regulating device and an air delivery pipe 1. A butterfly valve 2 for controlling the flow is installed on the air delivery pipe 1. In this embodiment, it is mainly realized by means of electropneumatic control. The control of the opening of the butterfly valve 2, wherein the pneumatic actuator 3 has a hollow inner cavity, and a piston A30 is elastically arranged in the hollow inner cavity, and the piston A30 is connected with the regulating rod of the butterfly valve 2 through the connecting rod 4, so that when the piston A30 is in the When sliding in a straight line in the hollow cavity, the butterfly valve 2 can be driven to rotate through the connecting rod 4, and the power source for the movement of the piston A30 is air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com