Refrigerator adopting single stirling cryocooler as cold source

A technology for refrigerators and refrigerators, which is applied to refrigerators, household refrigerators, household refrigeration devices, etc., can solve the problems of low energy utilization rate, underutilized cold source, inconvenient temperature adjustment and control, etc. Energy utilization rate, single defrosting method, quick distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

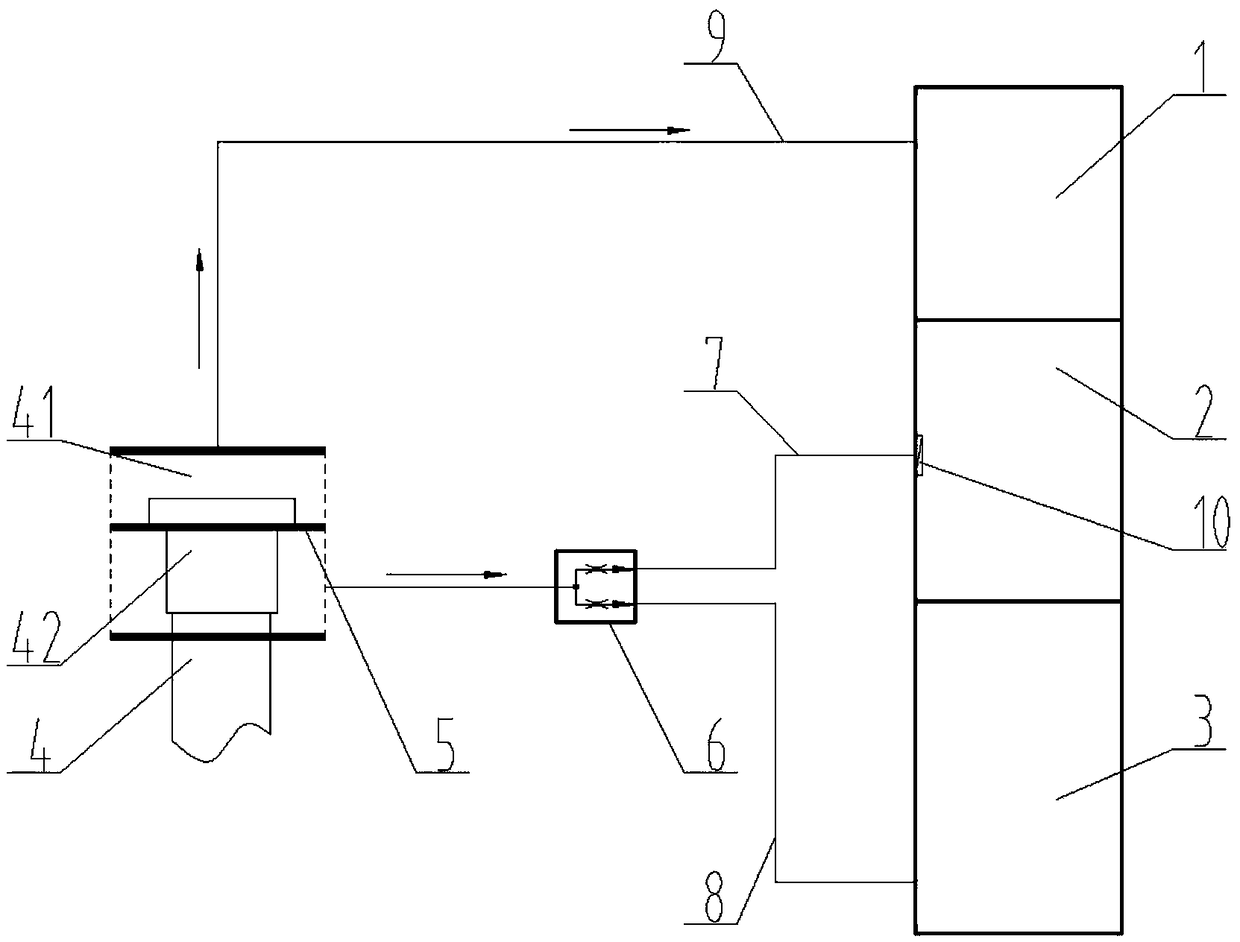

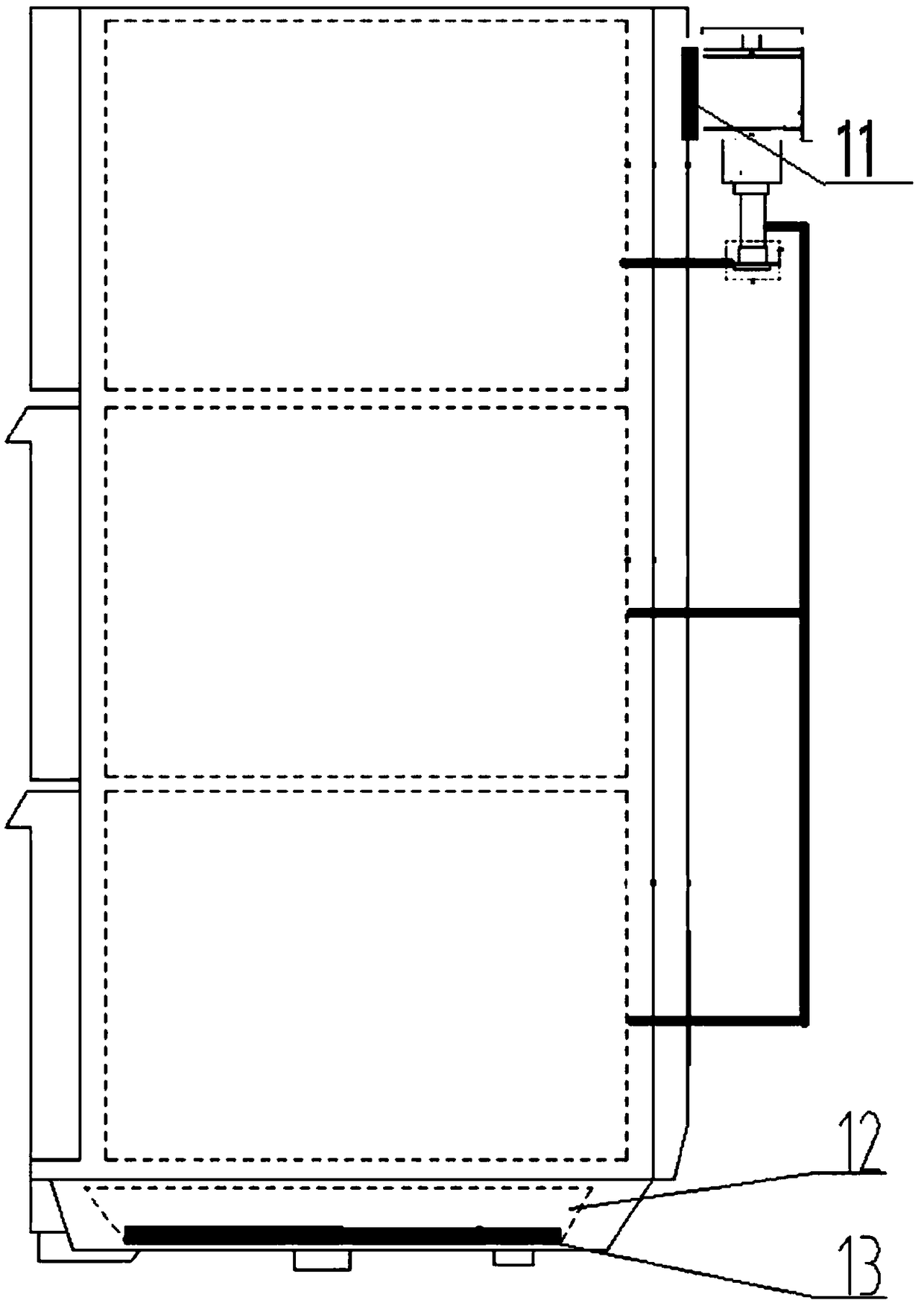

[0026] The content of the present invention will be further described in detail below in conjunction with specific embodiments. figure 1 It shows the arrangement diagram of the refrigeration circuit of the refrigerator using a single Stirling refrigerator as the cold source in the present invention. The refrigerator includes three temperature zones that are independent from each other and arranged in sequence from top to bottom. They are respectively named freezing zone 1, variable temperature zone 2 and refrigerating zone 3 according to the temperature and functionality of the cavity. In this embodiment, a Stirling refrigerator is used as a cooling source. The cold finger 4 of the Stirling refrigerator is separated into two parts by the heat insulation layer 5 , which are respectively a low temperature chamber 41 and a high temperature chamber 42 . The heat insulating layer 5 is made of heat insulating material, and is vertically sheathed on the cold finger 4 . The distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com