Power transmission tower defect identification method based on high-accuracy positioning multi-rotor unmanned aerial vehicle

A technology of multi-rotor UAV and power transmission tower, which is applied in the direction of optical test defect/defect, vehicle position/route/height control, non-electric variable control, etc., which can solve the problem of automatic image processing and image The shooting angle and quality cannot be guaranteed, and the hovering accuracy is restricted, so as to achieve the effect of realizing high-precision control, reducing the amount of calculation, and eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described in detail below with reference to the drawings and embodiments. However, it should be understood that these drawings are only designed for explanatory purposes, and therefore are not intended to limit the scope of the present invention. In addition, unless otherwise noted, these drawings are only intended to conceptually illustrate the structure described herein, and are not necessarily drawn to scale.

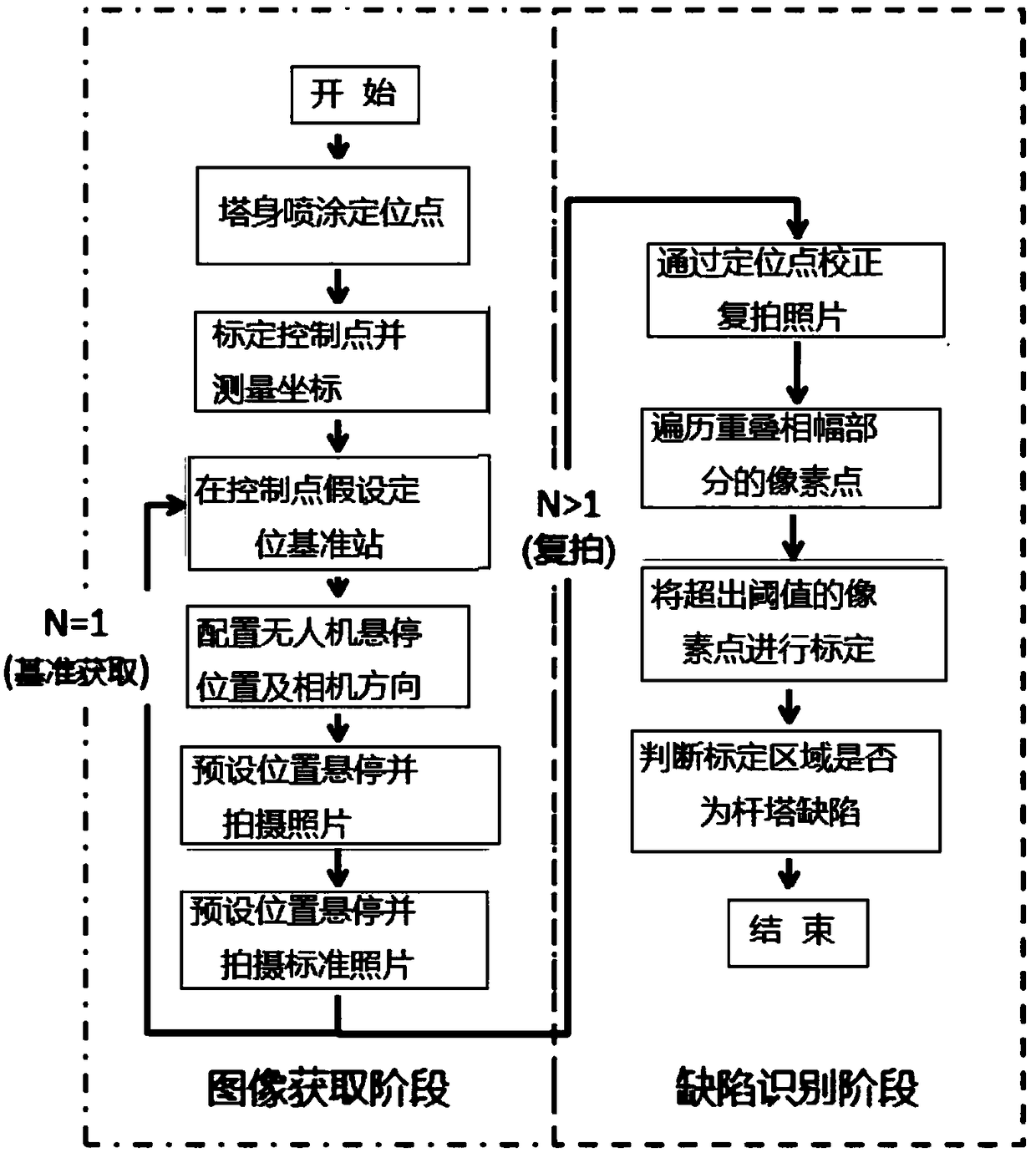

[0029] Combine below figure 1 The present invention will be explained in detail.

[0030] A method for identifying defects in a transmission tower of a multi-rotor UAV based on high-precision positioning includes the following steps:

[0031] 1. Spray three positioning points around the base of the transmission tower, the nameplate, and the tower body at the tower head.

[0032] Spray three white positioning points on the tower body. The shape of the map frame determined by the three positioning points ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com