Automatic freezing point tester and testing method

A test method and measuring instrument technology, applied in the investigation stage/state change, etc., can solve the problems of different thermal conductivity between the outer wall and the center of the container, the temperature deviation between the center of the oil and the outside, and the limitation of the detection structure, so as to prevent oil Stratified, increased contact area, the same effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now described in detail with accompanying drawings as follows. The embodiments described in the accompanying drawings are only used to illustrate the technical solutions of the present invention and are not limiting this invention.

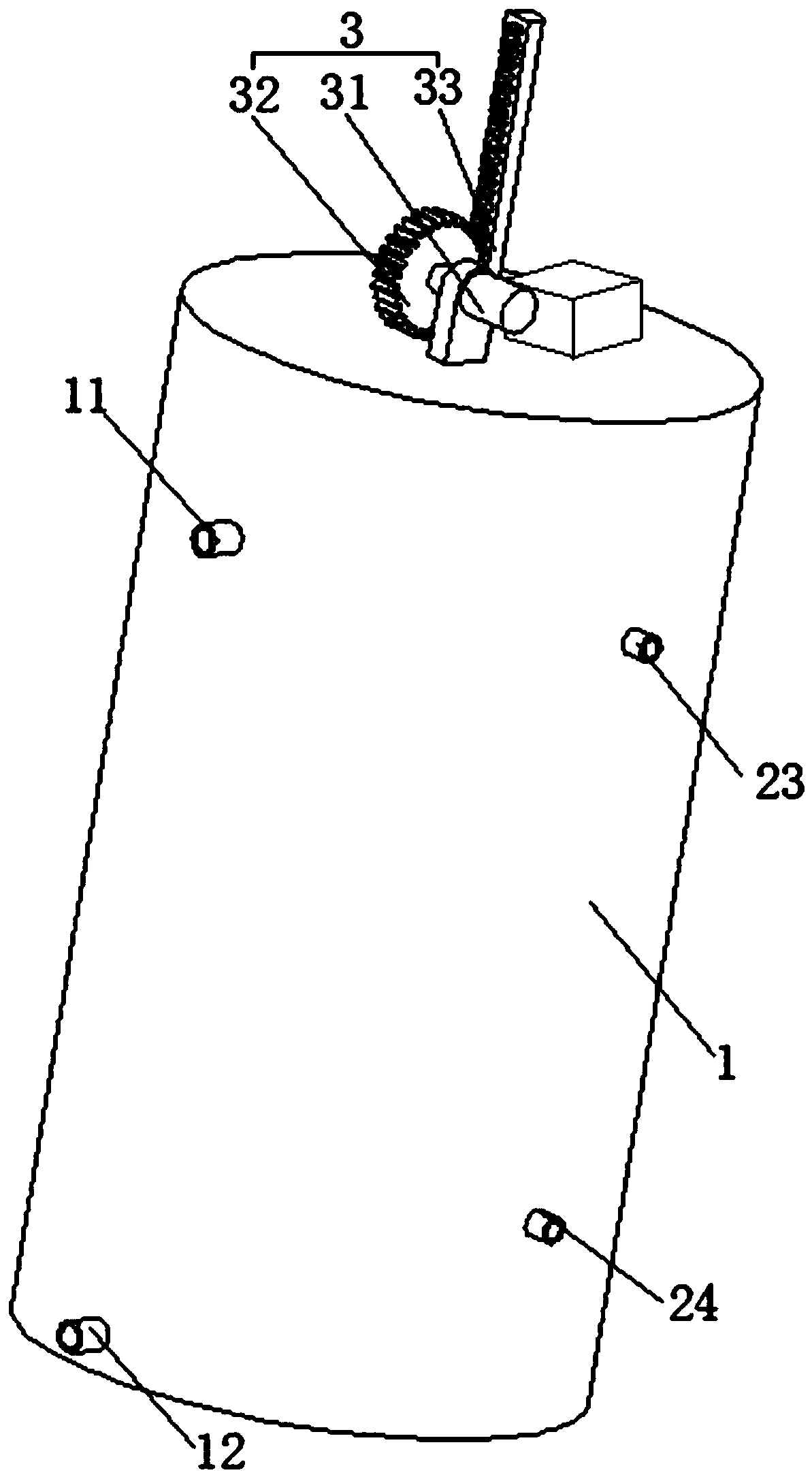

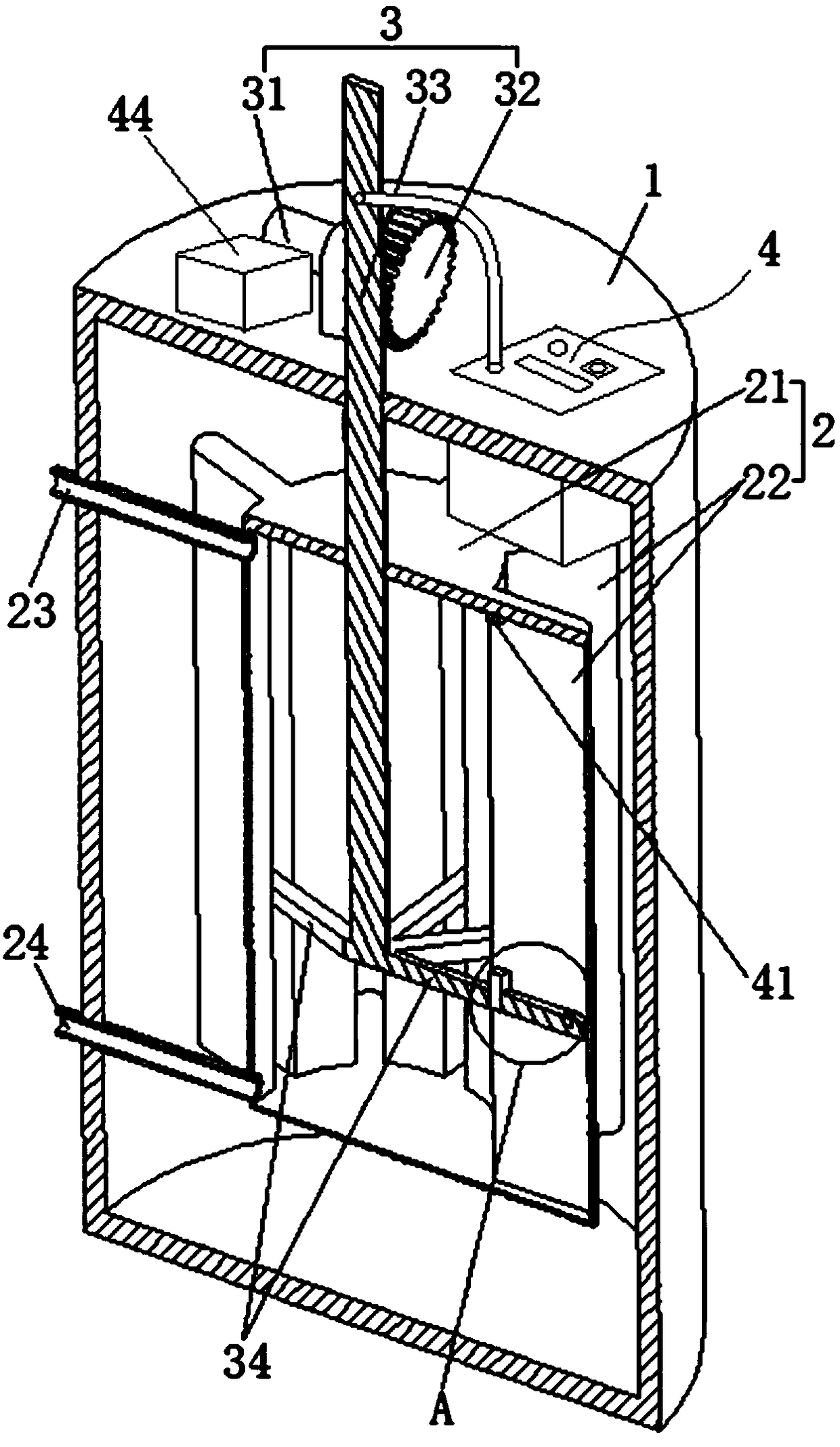

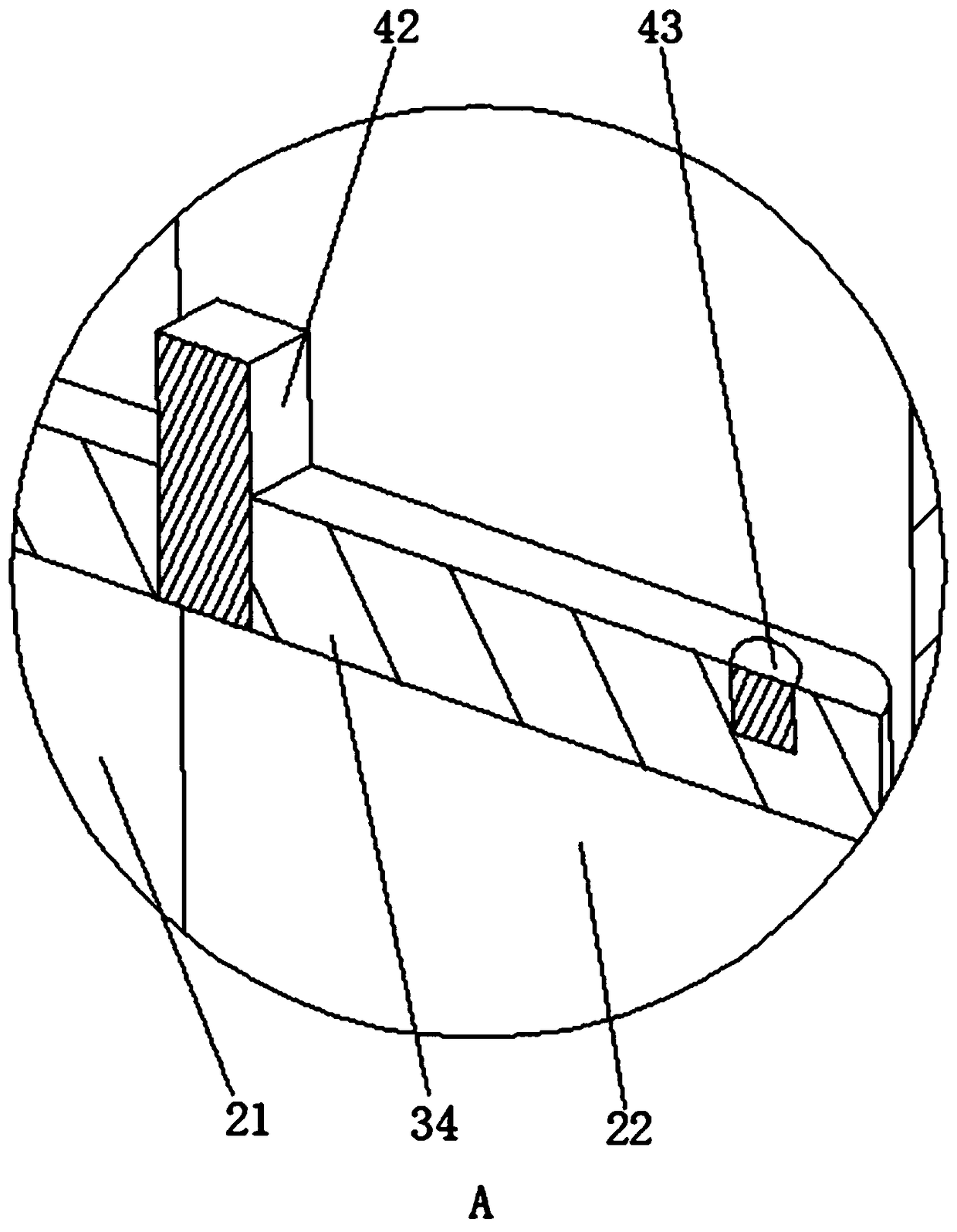

[0036] An automatic freezing point measuring instrument, combined with figure 1 , figure 2, including an outer cylinder 1, an inner cylinder 2, and a stirring member 3, the outer cylinder 1 is cylindrical, the inner cylinder 2 is fixedly connected in the outer cylinder 1, the outer diameter of the inner cylinder 2 is smaller than the inner diameter of the outer cylinder 1, and the upper end of the outer cylinder 1 is fixed A liquid inlet pipe 11 is connected, and a liquid outlet pipe 12 is fixedly connected to the lower end of the same side of the outer cylinder 1. A coolant flows inside the liquid inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com