Microwave variable-temperature differential-pressure puffing dryer

A technology of variable temperature and pressure difference puffing and drying machine, which is applied in food forming, food science, application, etc., and can solve problems such as uneven drying, high labor intensity, and lack of versatility of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

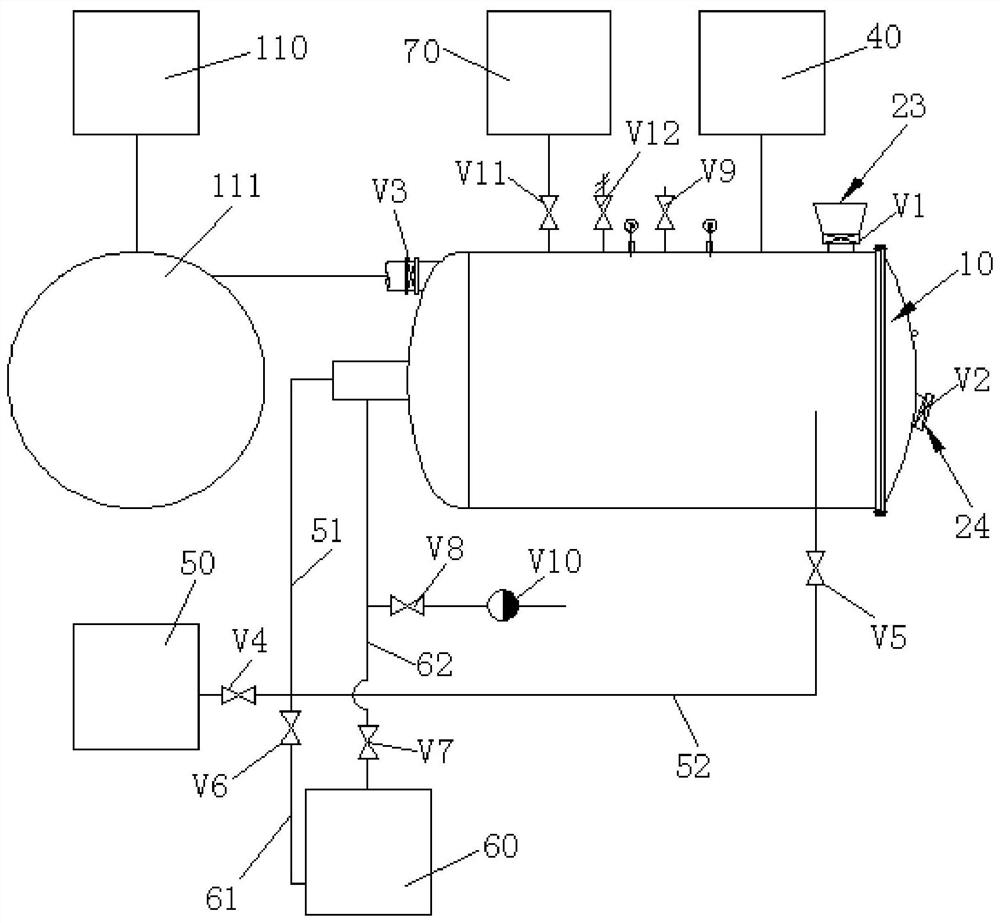

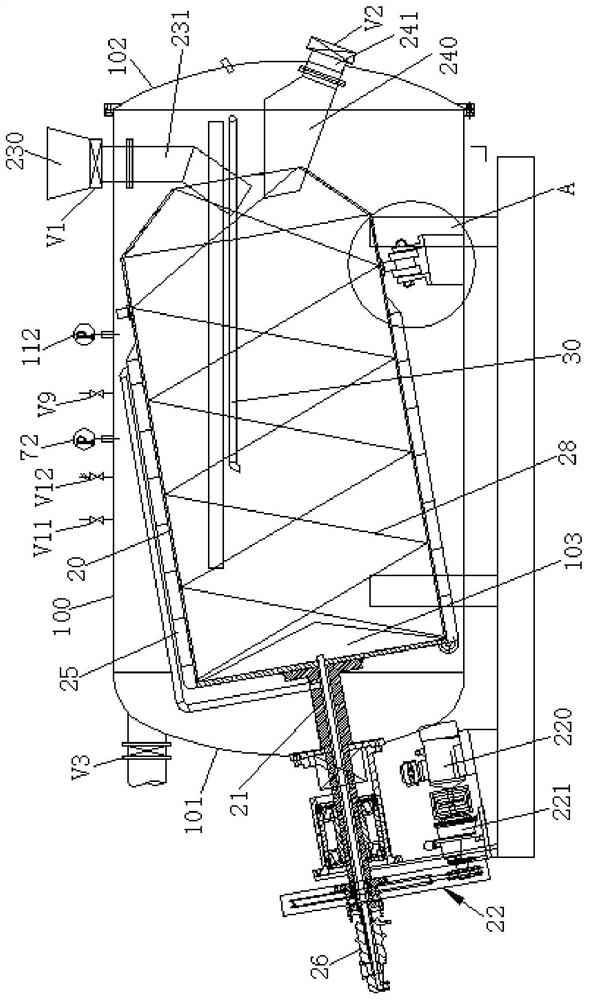

[0037] Please refer to the attached figure 1 And attached figure 2 Shown are the structural schematic diagram and partial cross-sectional structural schematic diagram of the microwave variable temperature and pressure difference puffing dryer of the present invention, respectively.

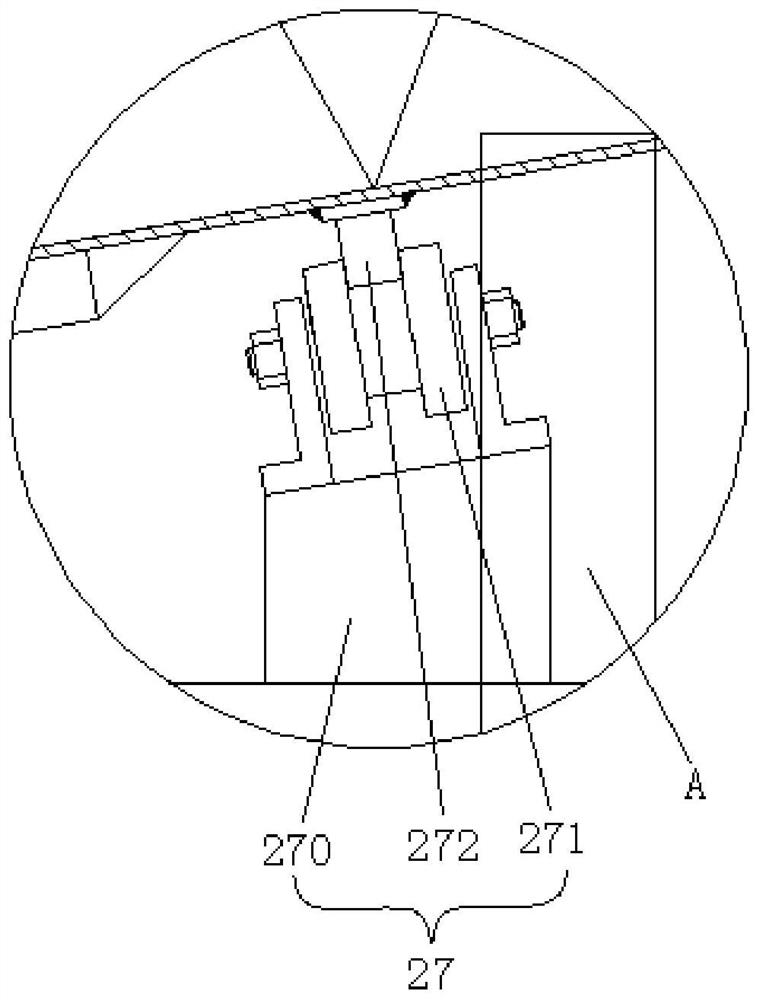

[0038] The microwave variable temperature and pressure difference puffing dryer of the present invention includes a pressure tank device, a rotary drying device, a softening device and a microwave heating system, wherein the pressure tank device has a pressure tank 10 which is a hollow structure and a function A vacuum system based on the pressure tank 10 and making the inner cavity of the pressure tank form a vacuum chamber; the rotary drying device has a drying cylinder 20, a hollow rotating shaft 21 and a power mechanism 22, and the drying cylinder 20 is closed on one side , a hollow structure with an opening on the other side, the drying cylinder 20 is movably built into the inner cavity of ...

Embodiment 2

[0057] The processing method of using the microwave variable temperature and pressure difference puffing dryer to process apple crisps:

[0058] Step 1. Turn on the power, turn on the automatic control system (including PC and PLC controller), input relevant parameters and programs through the touch screen man-machine dialogue interface of the PLC controller, and press the start button to enter operation;

[0059] Start the vacuum unit 110, set the vacuum degree of the pressure tank 10 to be -0.098MPa; start the steam generator 50, set the steam temperature to 100°C; start the chiller 60, set the cold water temperature to -15°C;

[0060] Step 2. After the steam generator 50 generates steam at 100°C, the motor 220 is controlled to start, and after power is transmitted through the reducer 221, two gears, a transmission toothed belt and the hollow shaft 21, it drives the The drying cylinder 20 rotates clockwise at a speed of 15r / min;

[0061] After the drying cylinder 20 rotate...

Embodiment 3

[0069] The processing method of using the microwave variable temperature and pressure difference puffing dryer to process French fries:

[0070] Step 1. Turn on the power, start the automatic control system (including PC and PLC controller), input relevant parameters and programs through the touch screen man-machine dialogue interface of the PLC controller, and press the start button to start operation;

[0071] Start the vacuum unit 110, set the vacuum degree of the pressure tank 10 to be -0.098MPa; start the steam generator 50, set the steam temperature to 120°C; start the chiller 60, set the cold water temperature to -15°C; start the air compressor 70 and set the air pressure to 0.4MPa;

[0072] Step 2. After the steam generator 50 generates steam at 120°C, the motor 220 is controlled to start, and after the power is transmitted through the reducer 221, two gears, a transmission toothed belt and the hollow shaft 21, it drives the The drying cylinder 20 rotates clockwise at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com