Clapping direct-acting normally-open relay

A normally open relay and direct-acting technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of many relay parts, large relay volume, and high cost, and achieve low manufacturing and assembly costs and small size , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the accompanying drawings and specific embodiments.

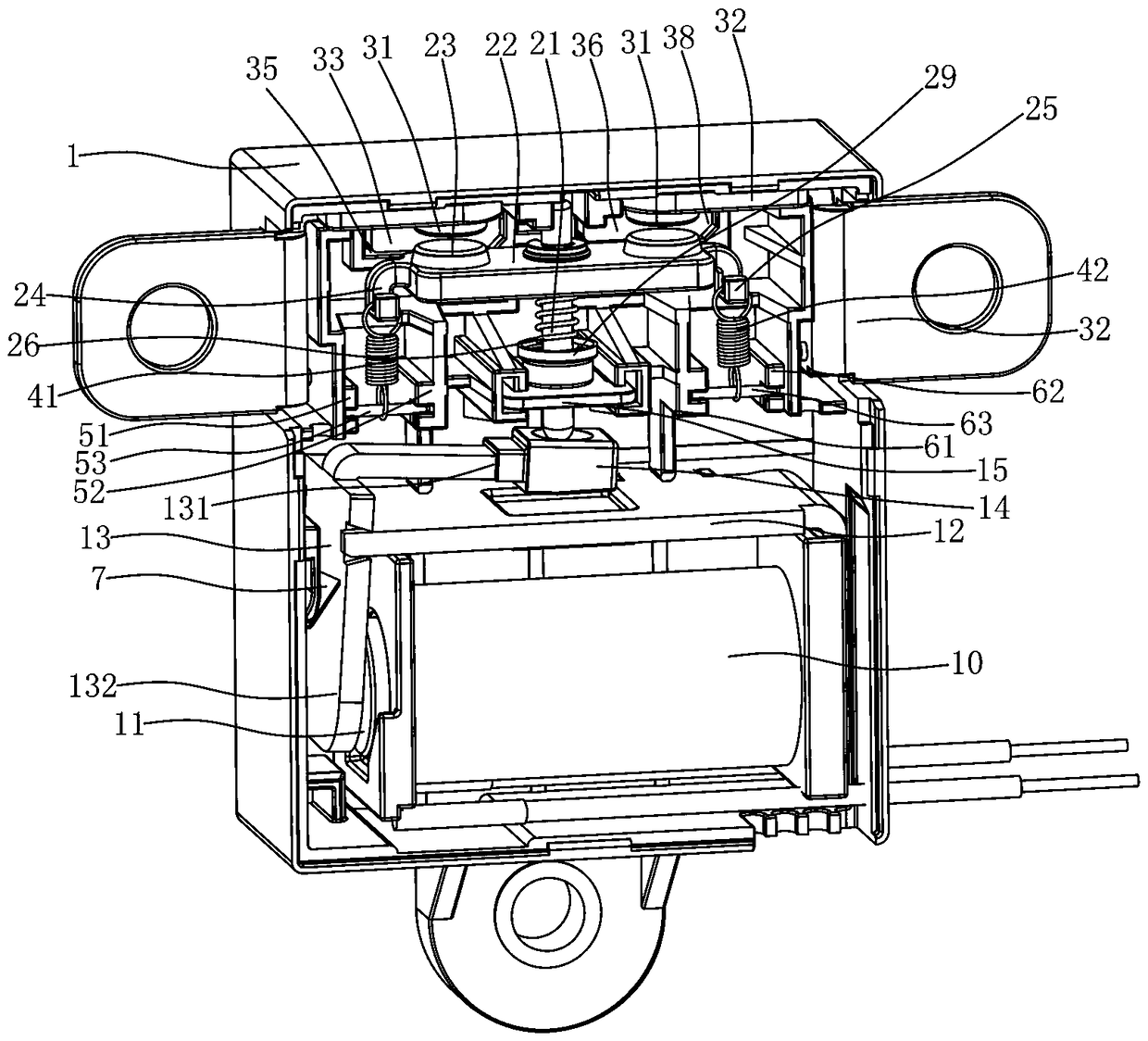

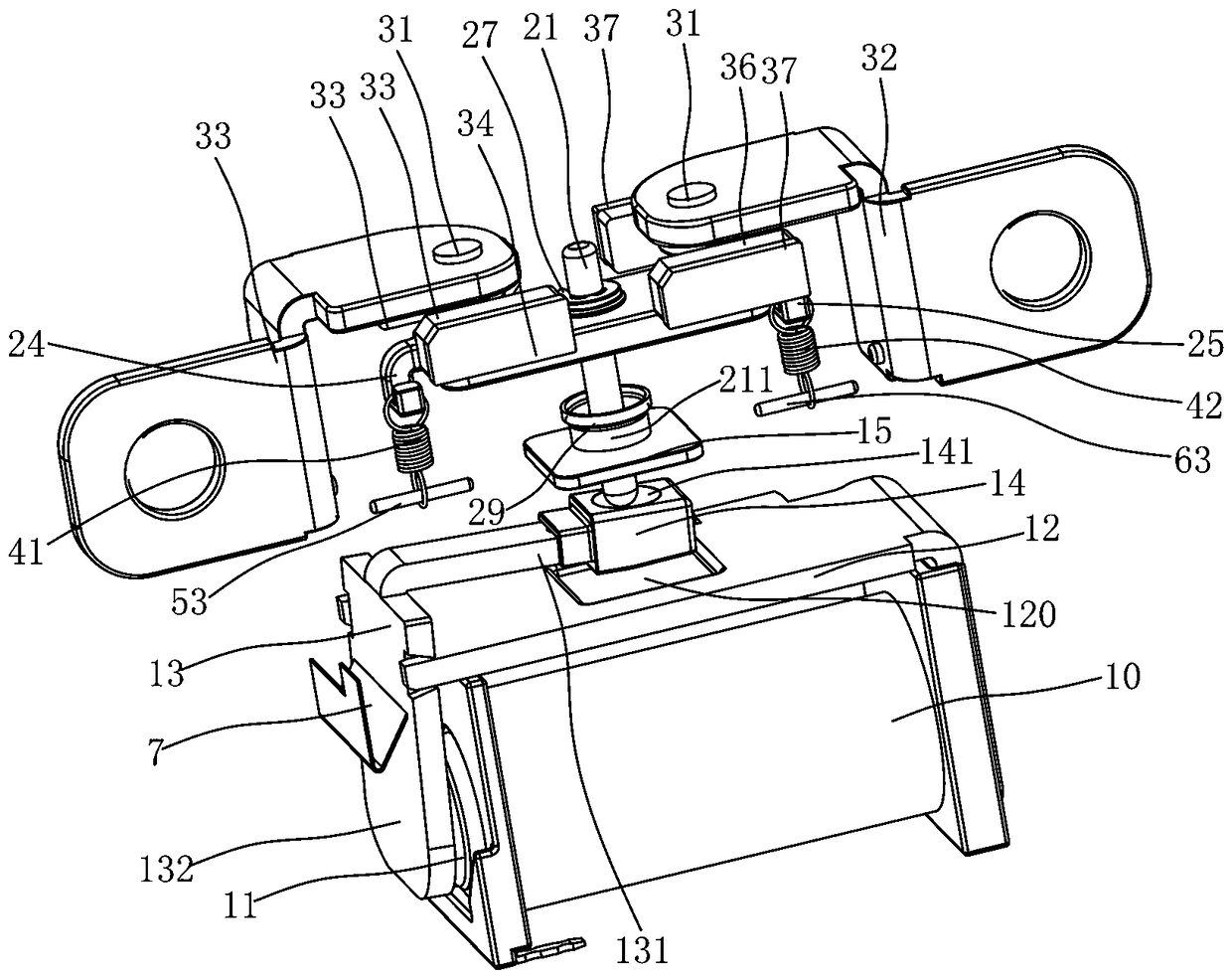

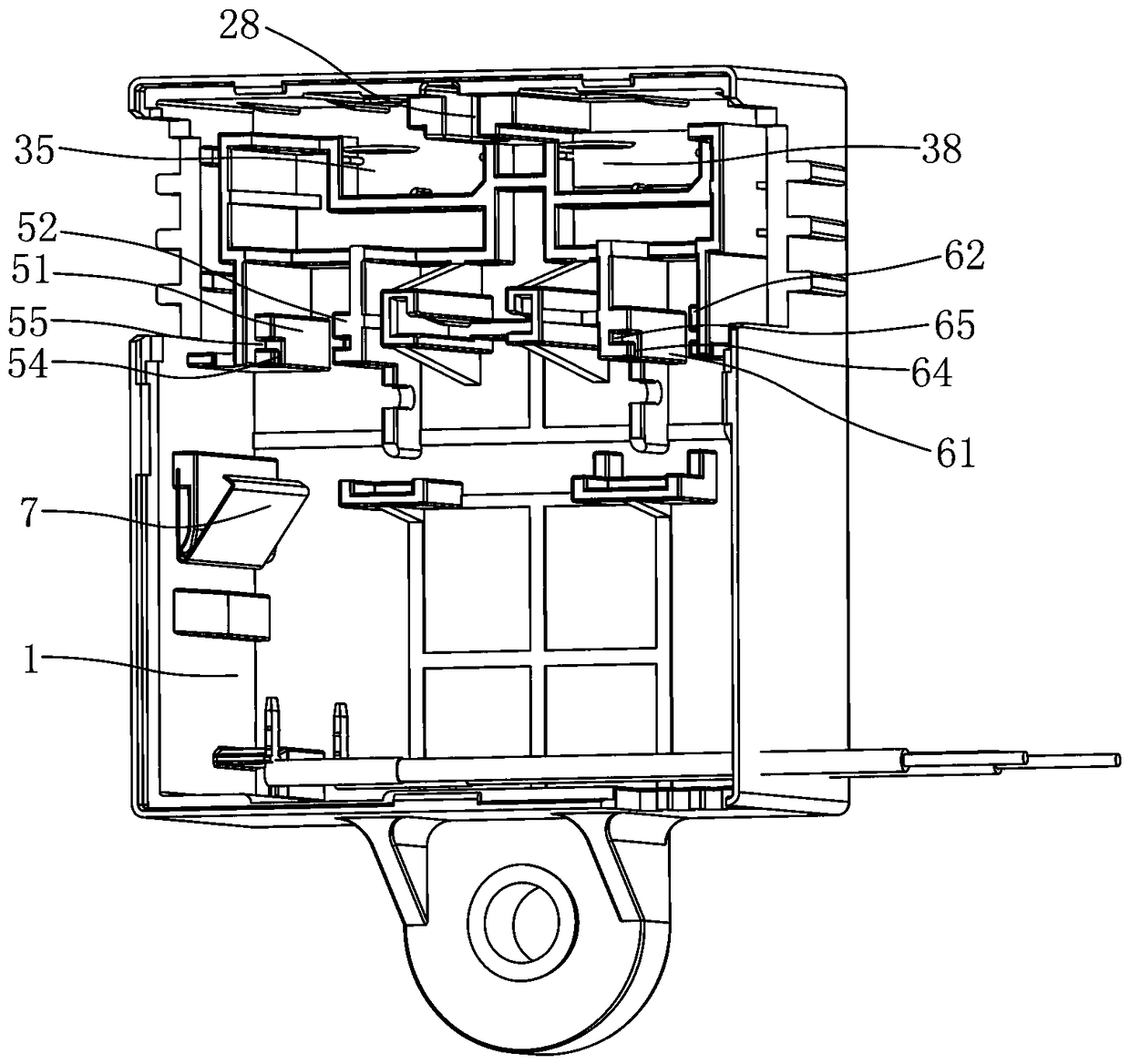

[0025] Depend on figure 1 , figure 2 , image 3 As shown, a clapping direct-acting normally open relay of the present invention includes a housing 1, and the housing 1 is provided with a magnetic circuit part, a moving contact part and a static contact part, and the magnetic circuit part includes a coil former 10 and The coil is arranged on the bobbin 10. The bobbin 10 is formed with a through-slot penetrating left and right. An iron core 11 is arranged in the through-slot. One end of the L-shaped yoke 12 is fixed to the right end 11 of the iron core. The L-shaped yoke 12 The other end of the armature 13 is located on the upper side of the coil frame 10 and is matched with the armature 13. The two ends of the armature 13 are respectively the trigger end 131 and the attraction end 132. The upper side of the yoke 12 is located on the lower side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com