A Tool Life Prediction Method

A technology of tool life and prediction method, applied in manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of tool life impact, increase safety hazards, reduce the yield of production products, etc., to speed up the calculation speed and calculation. Accuracy, reduce safety hazards, and improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

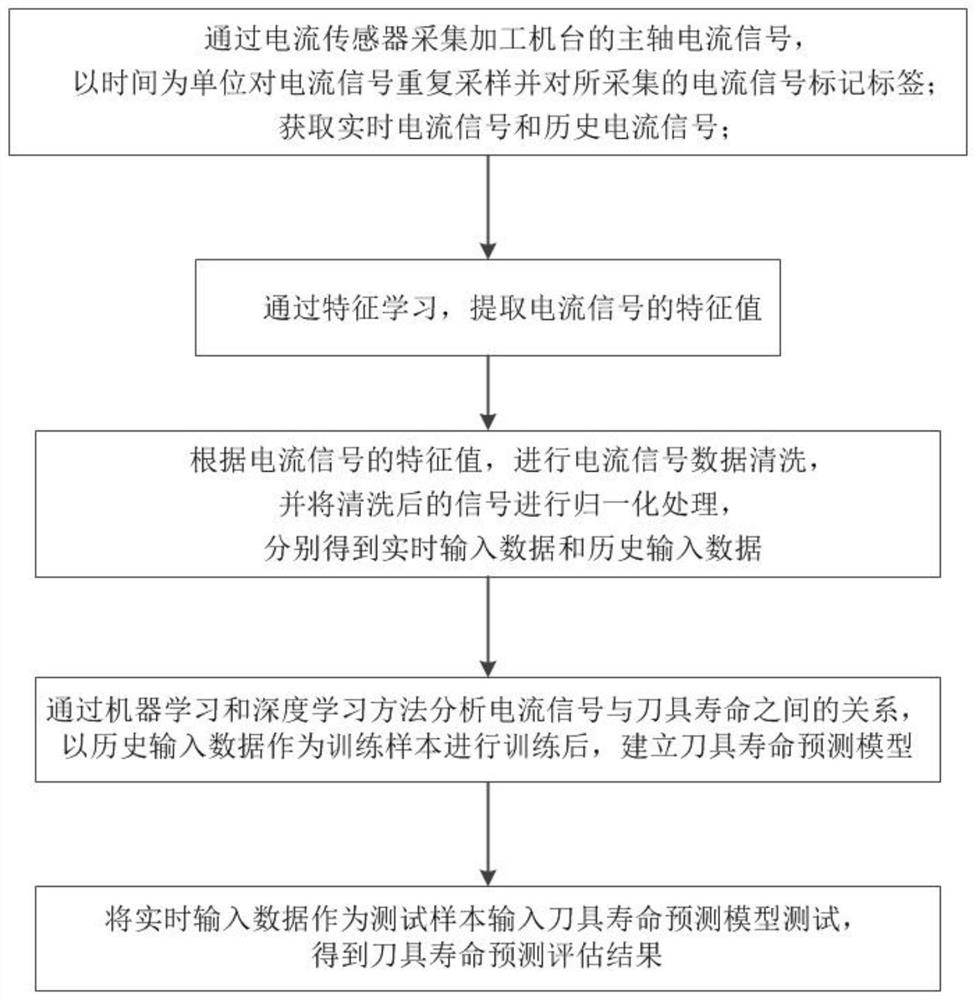

[0020] In this example, see figure 1 As shown, the present invention proposes a tool life prediction method, comprising steps:

[0021] S1, collect the spindle current signal of the processing machine through the current sensor, repeatedly sample the current signal in units of time and label the collected current signal; obtain real-time current signal and historical current signal;

[0022] S2, extracting the eigenvalues of the current signal through feature learning;

[0023] S3. Cleaning the current signal data according to the characteristic value of the current signal, and normalizing the cleaned signal to obtain real-time input data and historical input data respectively;

[0024] S4, analyze the relationship between the current signal and tool life through mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com