Drive system for change of pitch of helicopter tail rotor and helicopter

A helicopter tail rotor and drive system technology, applied in the field of helicopters, can solve the problems of reducing the service life of tie rod bearings, increasing structural weight, and reducing transmission reliability, so as to achieve the effect of optimizing the force transmission path and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

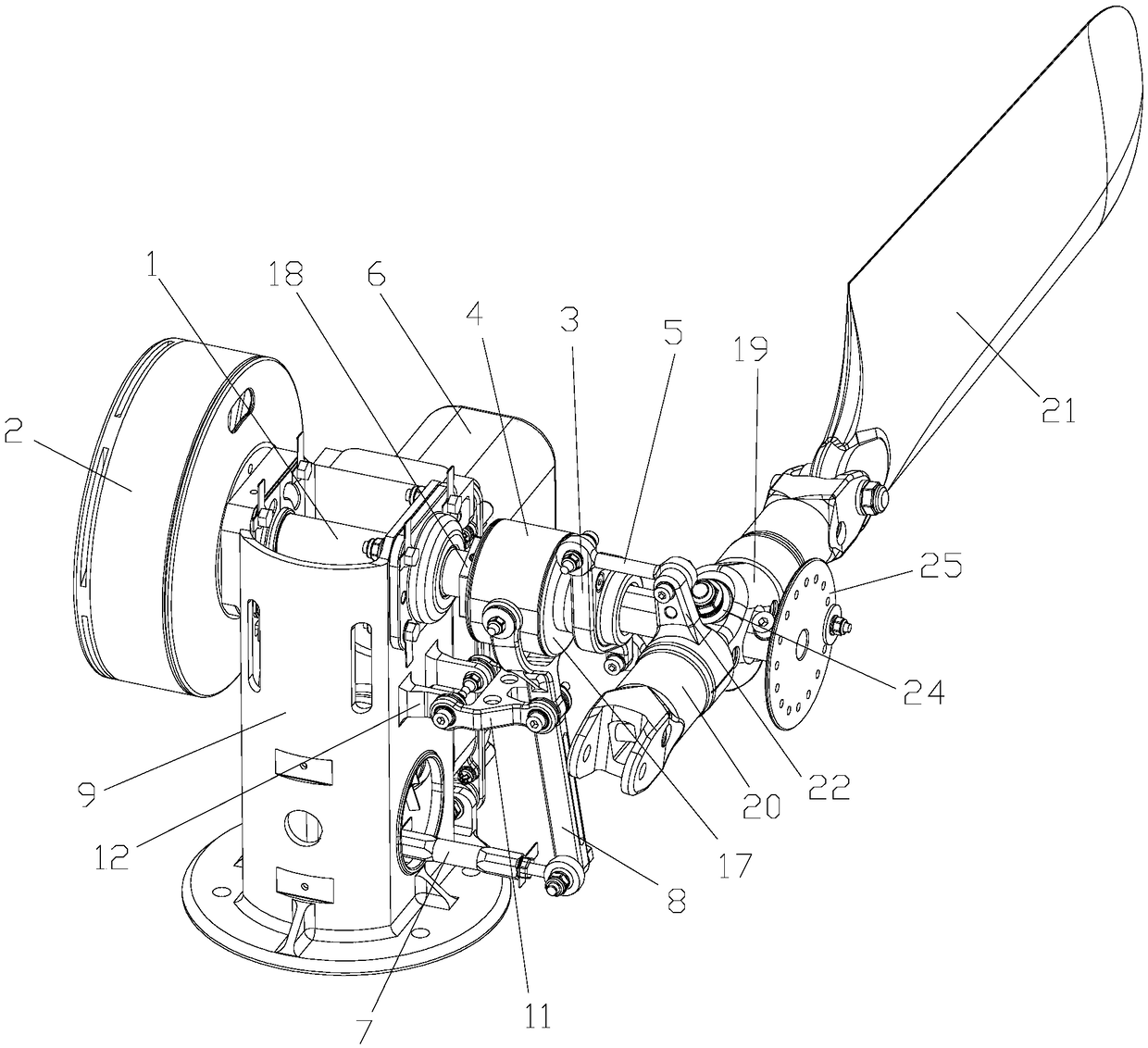

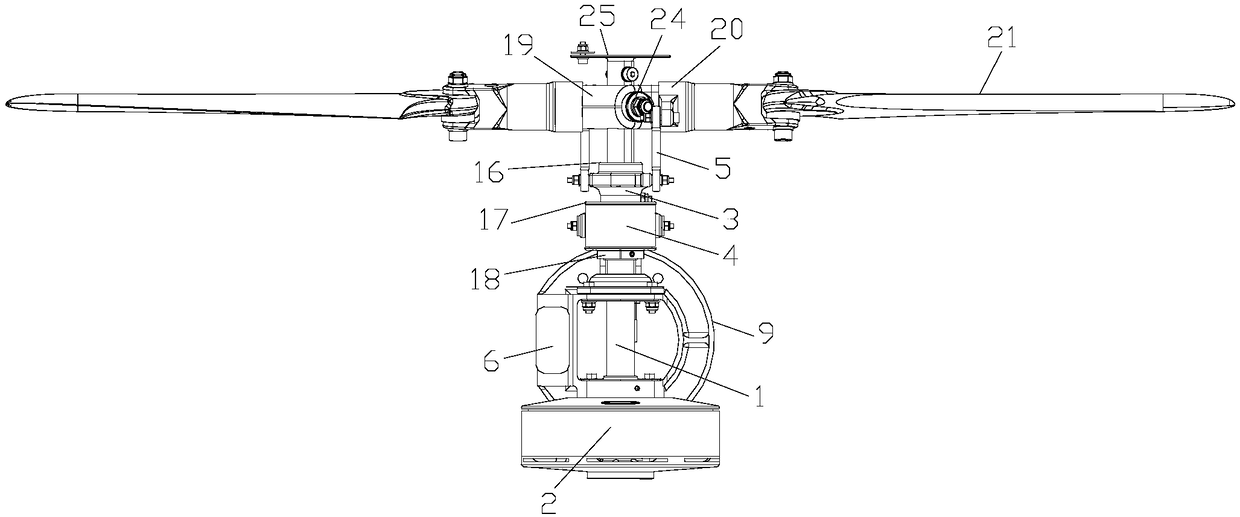

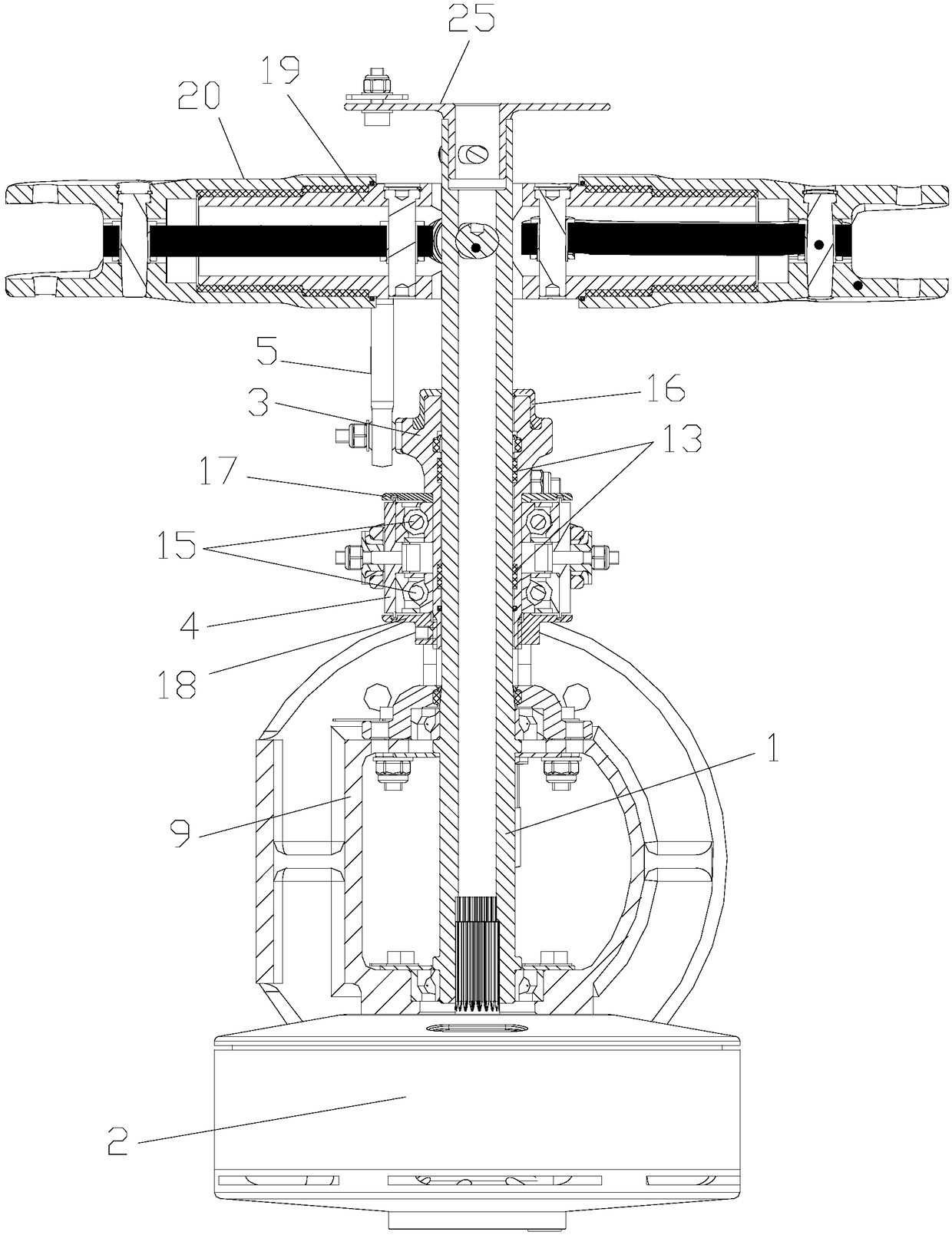

[0023] Such as Figure 1 to Figure 6 Shown: the helicopter tail rotor pitch variable drive system of this embodiment includes a tail rotor rotor shaft 1 and a pitch variable mechanism for driving the tail rotor blade assembly to rotate, and the pitch variable mechanism includes a 1 is axially slid and matched with the tail rotor shaft 1 in a transmission manner, and is overlaid on the pitch change disc 3 of the tail rotor shaft 1, and the pitch change sleeve 4 is overlaid on the pitch change disc 3 for driving the pitch change disc 3 to slide, and The drive assembly that drives the pitch change sleeve 4 to slide axially along the tail rotor shaft 1, the pitch change disc 3 is provided with a transmission rod 5 for connecting with the blade assembly, through the pitch change disc 3 and the tail rotor shaft 1. Transmission cooperation, so that the pitch variable disc 3 rotates with the tail rotor shaft 1, and the tail rotor shaft 1 drives the tail rotor blade assembly to rotate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com