Large tonnage tower crane oversized load attachment wall structure used in high wind environment

A tower crane and environmental technology, applied in the direction of cranes, etc., can solve the problems that the structural force cannot meet the requirements, affect the total construction period and construction cost, and affect the construction efficiency of the main tower, so as to achieve simple structure, reduce construction cost, good economic benefits and The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

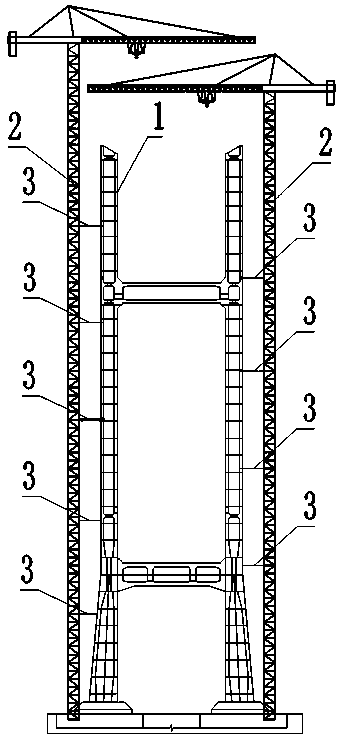

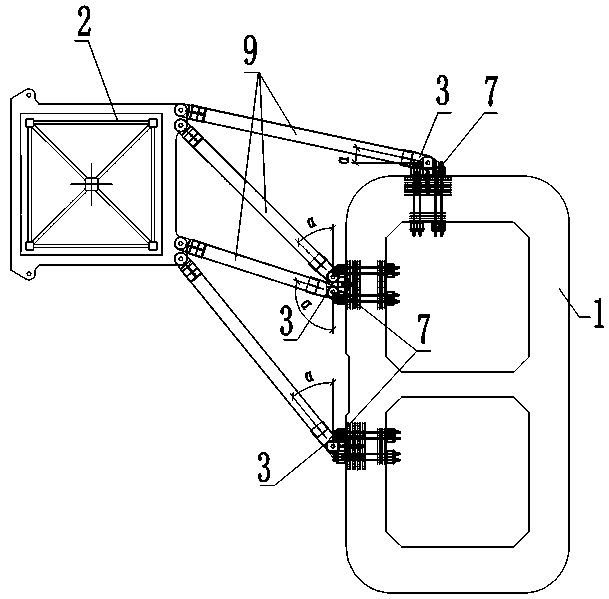

[0020] The concrete main tower 1 is divided into thirty-four sections in the height direction, and two tower cranes are arranged, the tower crane 2 is higher on the left side, the shorter tower crane 2 is on the right side, and the tower crane 2 on the left side is arranged with a wall-attached structure 3, five, and the tower crane 2 on the right is arranged with 3 or four wall-attached structures.

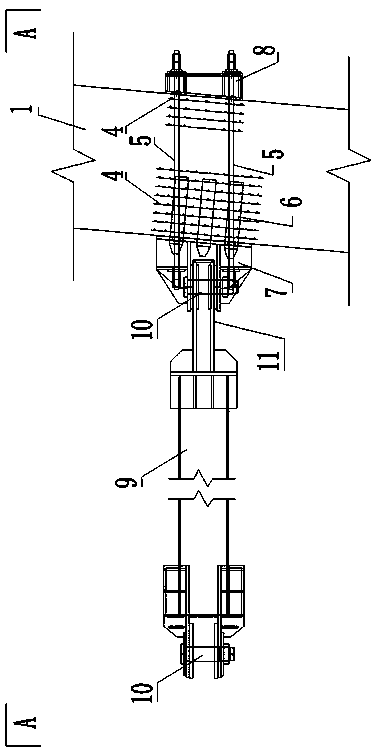

[0021] A wall-attached structure for super-large loads of a special tower crane in a strong wind environment, consisting of reinforced steel mesh 4, precision-rolled threaded steel bars 5, steel rods 6, connecting seats 7, anchor seats 8, attachment rods 9, and pin shafts 10, of which: reinforcement The reinforced mesh sheet 4 is installed in the main tower 1, and the reinforced reinforced mesh sheet 4 is to strengthen the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com