Preparation method of ternary nickel cobalt manganese anode material precursor capable of changing stacking mode of microcrystalline particle

A technology of particle accumulation and positive electrode material is applied in the field of preparation of ternary nickel-cobalt-manganese positive electrode material precursor, which can solve the problems of complicated operation, difficult to meet the existing production and high cost, and achieve high battery capacity, low cost, and guaranteed products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

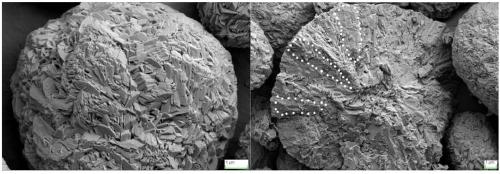

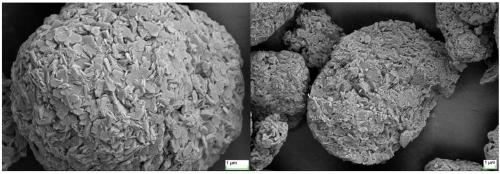

Examples

Example Embodiment

[0024] Example 1

[0025] (1) The concentration of nickel, cobalt and manganese metal salt solution is 2mol / L, the concentration of ammonia water is 8-10%, and the concentration of lye is 4mol / L of sodium hydroxide solution; the chemical formula of the nickel, cobalt and manganese precursor is Ni (1-xy)CoxMny(OH)2, where 0.1≤x≤0.2, 0.1≤y≤0.3;

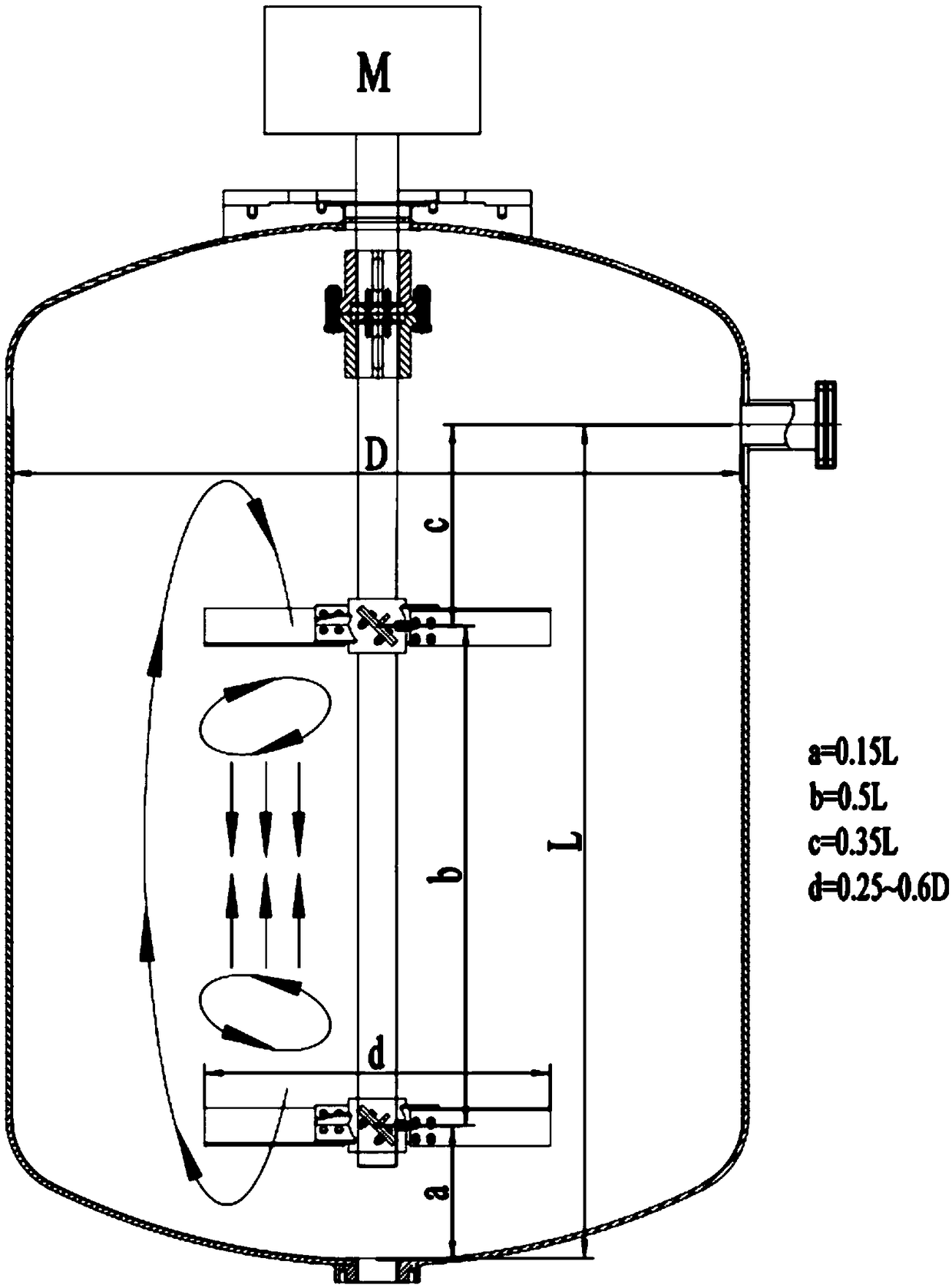

[0026] (2) Improve the structure of the reactor blade: the reactor blade adopts an open turbine 45° oblique blade blade; the diameter of the adjustment blade is 0.5D, and D is the diameter of the reactor; the number of blades is double-layered, and each layer of blades The number of blades is 6; adjust the pitch of the blade layer, the vertical distance between the lower blade and the discharge port at the bottom of the reactor is 0.15L, L is the effective height of the reactor, that is, the horizontal center line of the overflow port of the reactor to the bottom discharge port The vertical distance between the lower blade and the upper bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com