Pushing segmented hydraulic synchronous lifting assembling method for furnace shell of blast furnace

A hydraulic synchronous lifting and assembly method technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as long shutdown time, large production impact, and large safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

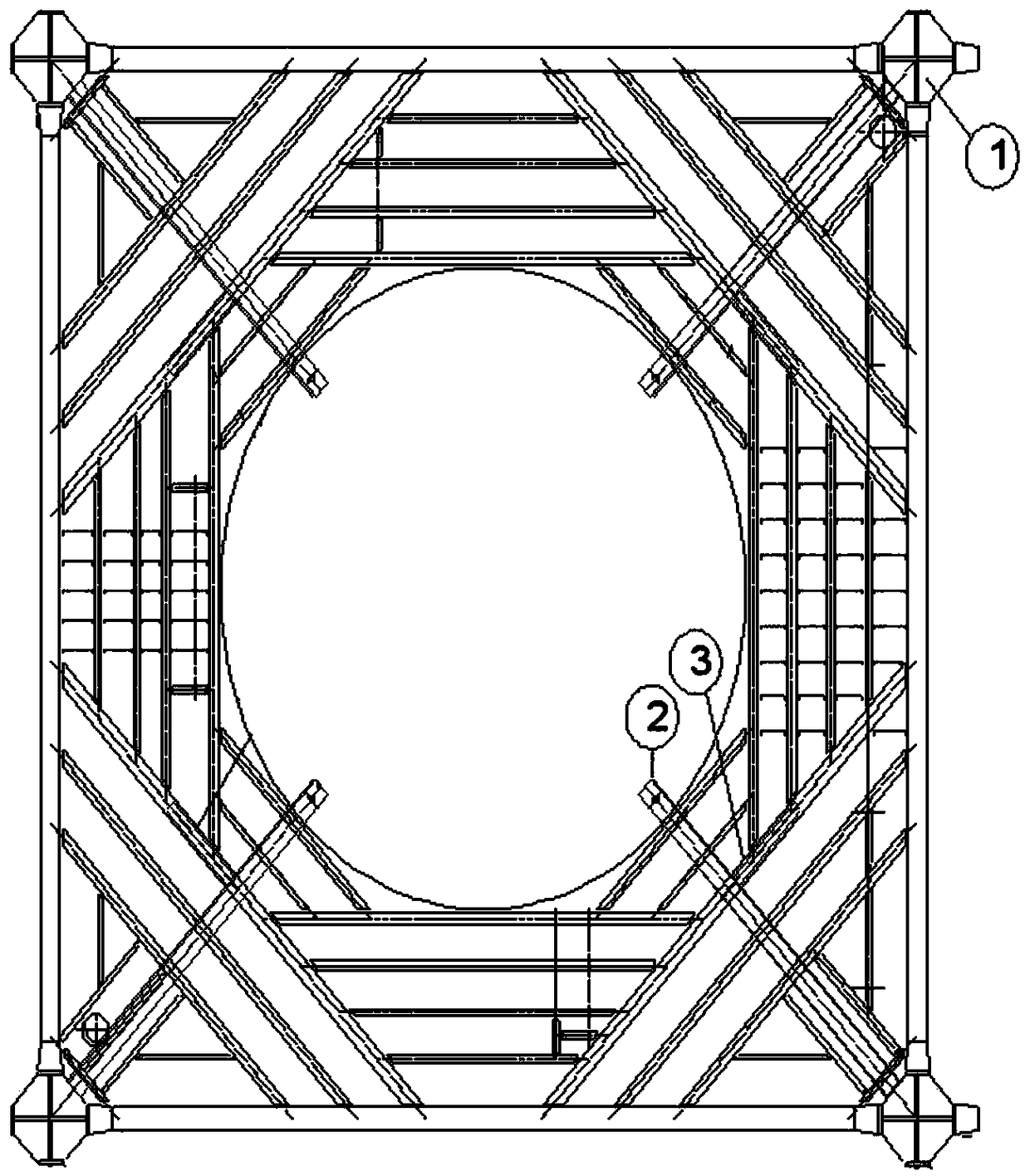

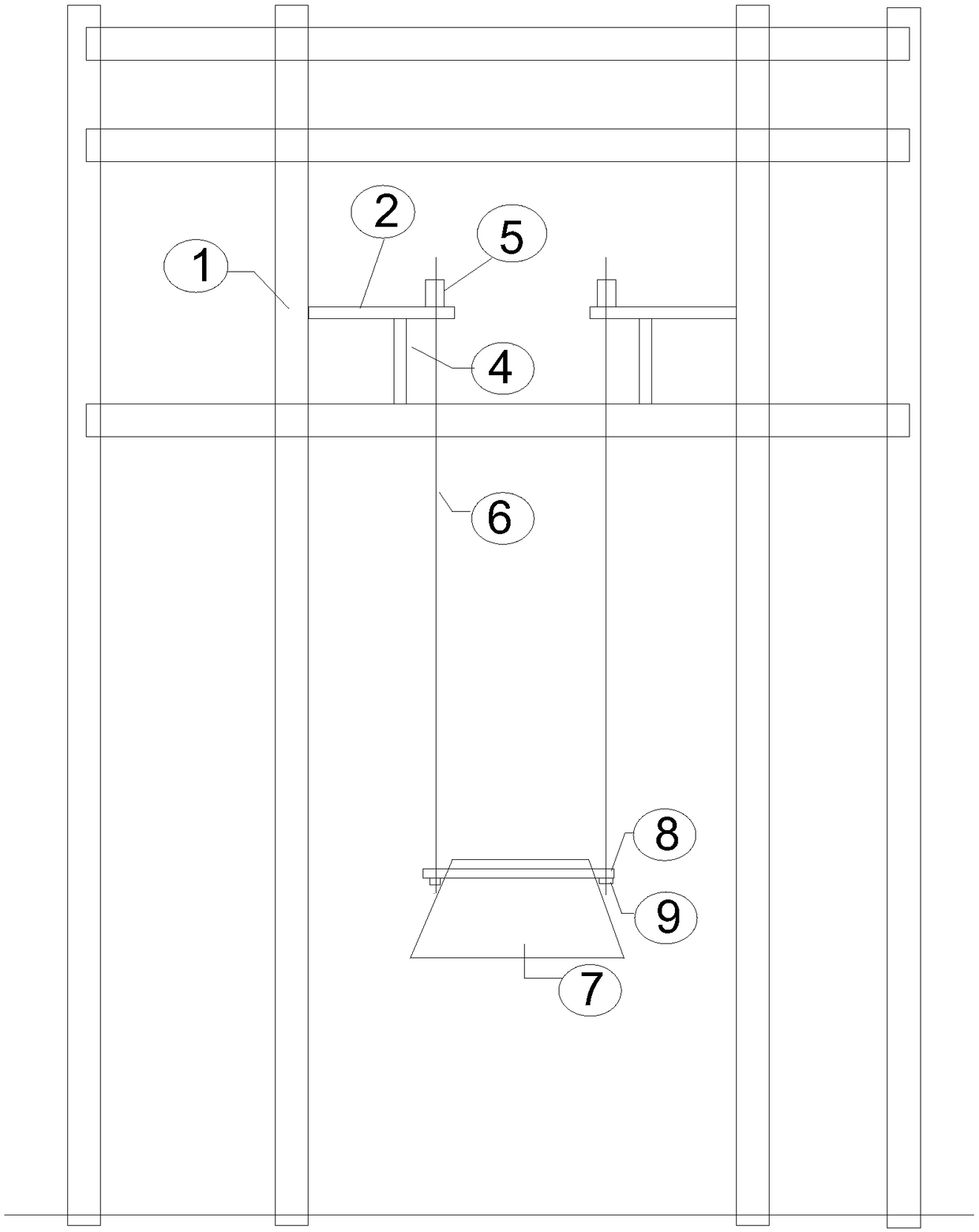

[0028] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0029] A blast furnace shell pushing segmental hydraulic synchronous lifting assembly method, comprising the following steps:

[0030] (1) On the four corner columns of the steel structure frame of the original old blast furnace body frame, the cantilevered steel beams of the hydraulic synchronous lifting system are welded horizontally. The cantilevered steel beams are made of H-shaped steel (HN700x300x13x24), and the cantilevered steel beams and the frame When welding the corner columns, the welding quality must be guaranteed, and the welding should be strengthened with stiffening plates; the length of the can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com