Porcelain plate curtain wall system

A curtain wall and porcelain plate technology, applied to walls, building components, buildings, etc., can solve the problems of low efficiency and achieve the effects of convenient installation, high safety and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

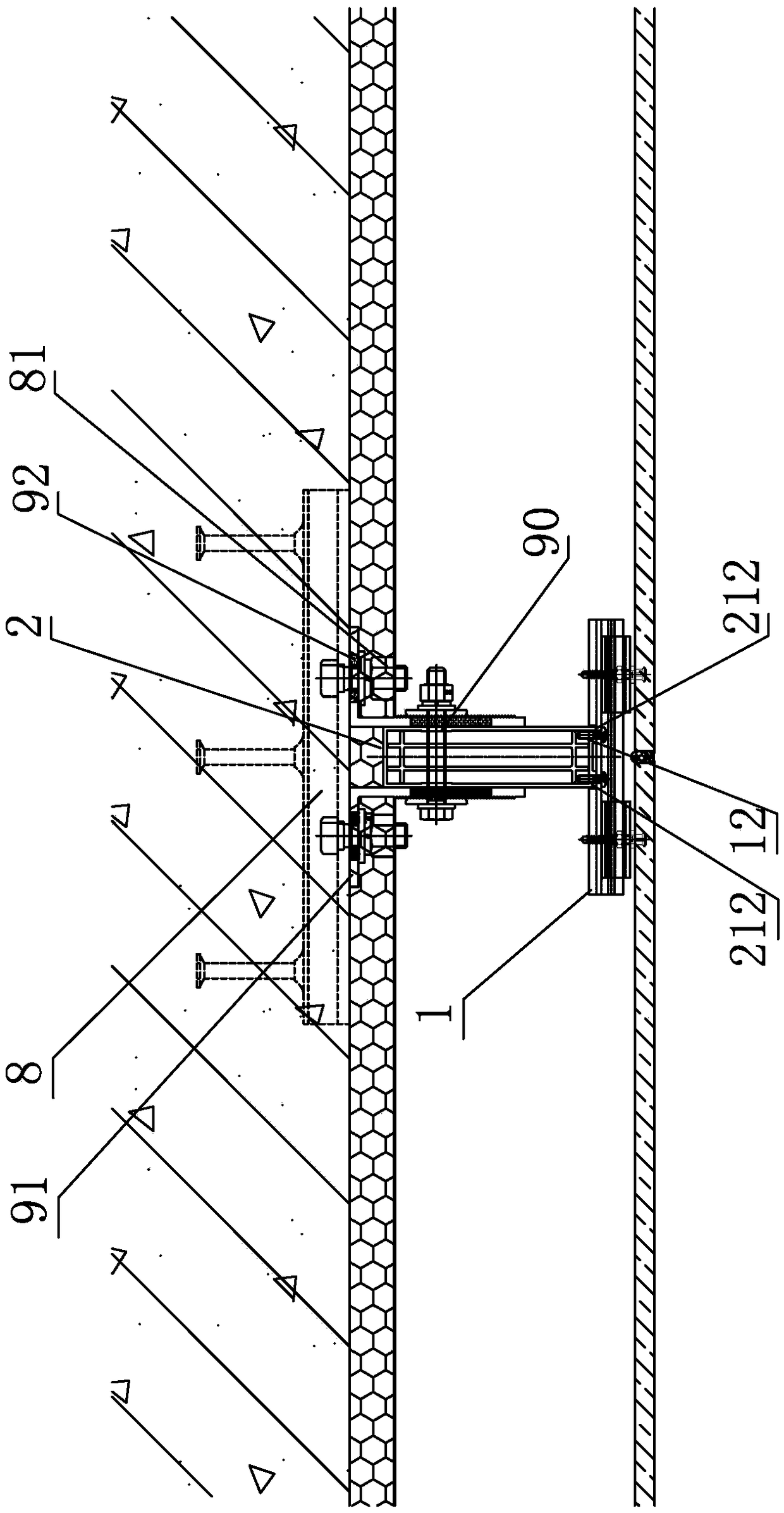

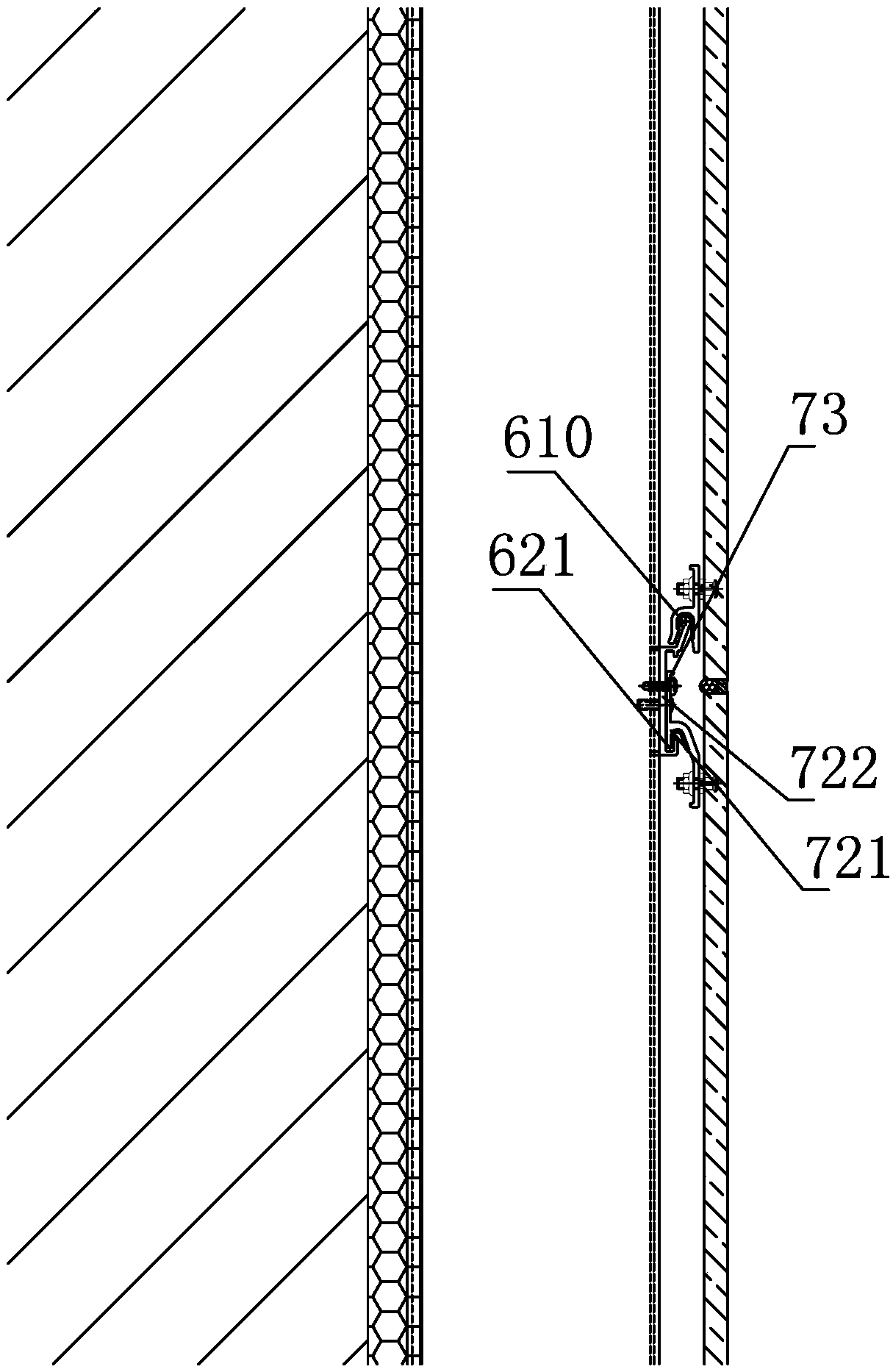

[0027] Refer to attached picture. The porcelain panel curtain wall system provided by the present invention includes embedded parts 8 , a plurality of columns 2 and a plurality of beams 1 , the columns 2 are connected to the embedded parts 8 through corner brackets, and the beams 1 are connected to the columns 2 .

[0028] The beam 1 and the column 2 are aluminum alloy profile beams and aluminum alloy profile columns respectively, the beam 1 is a short beam and is pressed on the front of the column 2, the two sides of the beam 1 exceed the column 2, and at the protruding part 10 and The hanging parts of the curtain wall panels are connected; the columns 2 are mutually independent columns, and the beam 1 is not arranged between the adjacent columns, and the two ends of the beam are not connected with the adjacent columns, and the beam can be as follows: figure 1 For the short-winged beam shown, the length of the excess part 10 only meets the need for hooking the curtain wall pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com