Fine manufacturing and mounting method for multi-purpose construction safety enclosure

An installation method and multi-purpose technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as damage to the finish, affect the quality of the installation, and easy cracking of the finish, so as to achieve rapid installation and disassembly, and detailed production Perfect, good firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

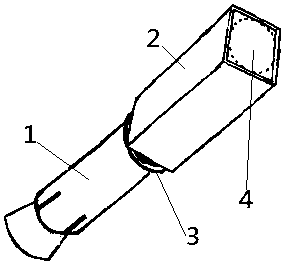

[0020] A multi-purpose construction safety enclosure fine production and installation method, such as figure 1 shown, including the following steps:

[0021] Step 1. Process positioning: Stakeout positioning on the ground surface, stakeout positioning at the height position of the steps, and stakeout positioning of the metal expansion screw 1;

[0022] Step 2, pre-embedding process: vertical depth-limited drilling at the center of the finished surface on the ground, and vertical fastening and installation of casing 2;

[0023] Step three, process installation:

[0024] ①Preliminary enclosure: the supporting enclosure railings are inserted into the casing 2 and connected to the handrails;

[0025] ② Finished product installation: pull out the fence, insert the finished column into the casing 2, and connect the handrail.

[0026] Because one end of the metal expansion screw 1 is threadedly connected with the nut, it can quickly install and disassemble the fence and finished c...

Embodiment 2

[0028] On the basis of Embodiment 1, a pad roll 3 is provided between the metal expansion screw 1 and the casing 2 to improve the connection stability between the metal expansion screw 1 and the casing 2 .

[0029] The casing 2 is made into different shapes according to actual needs. Preferably, the cross section of the casing 2 is circular or square, and the diameters of the metal expansion screw 1 and the casing 2 are 22mm and 25mm respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com