Cross type X air film hole cooling structure used for turbine blade

A technology of turbine blades and air film holes, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of large aerodynamic loss and complex processing of cylindrical holes, and achieve low cost, simple processing, and increased span overlay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

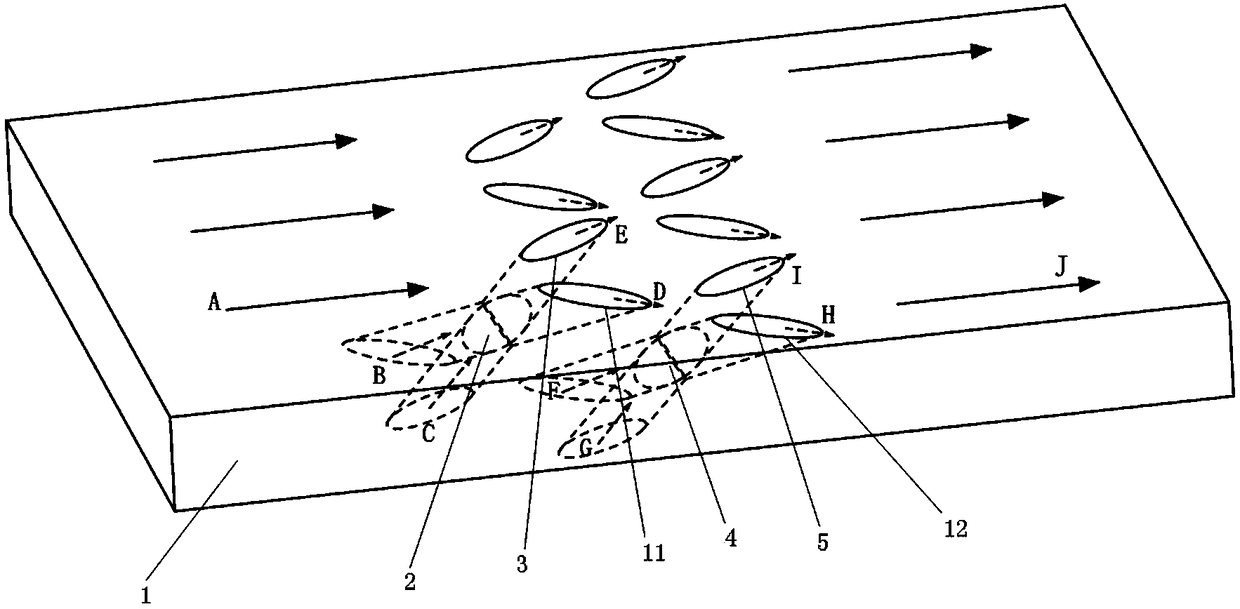

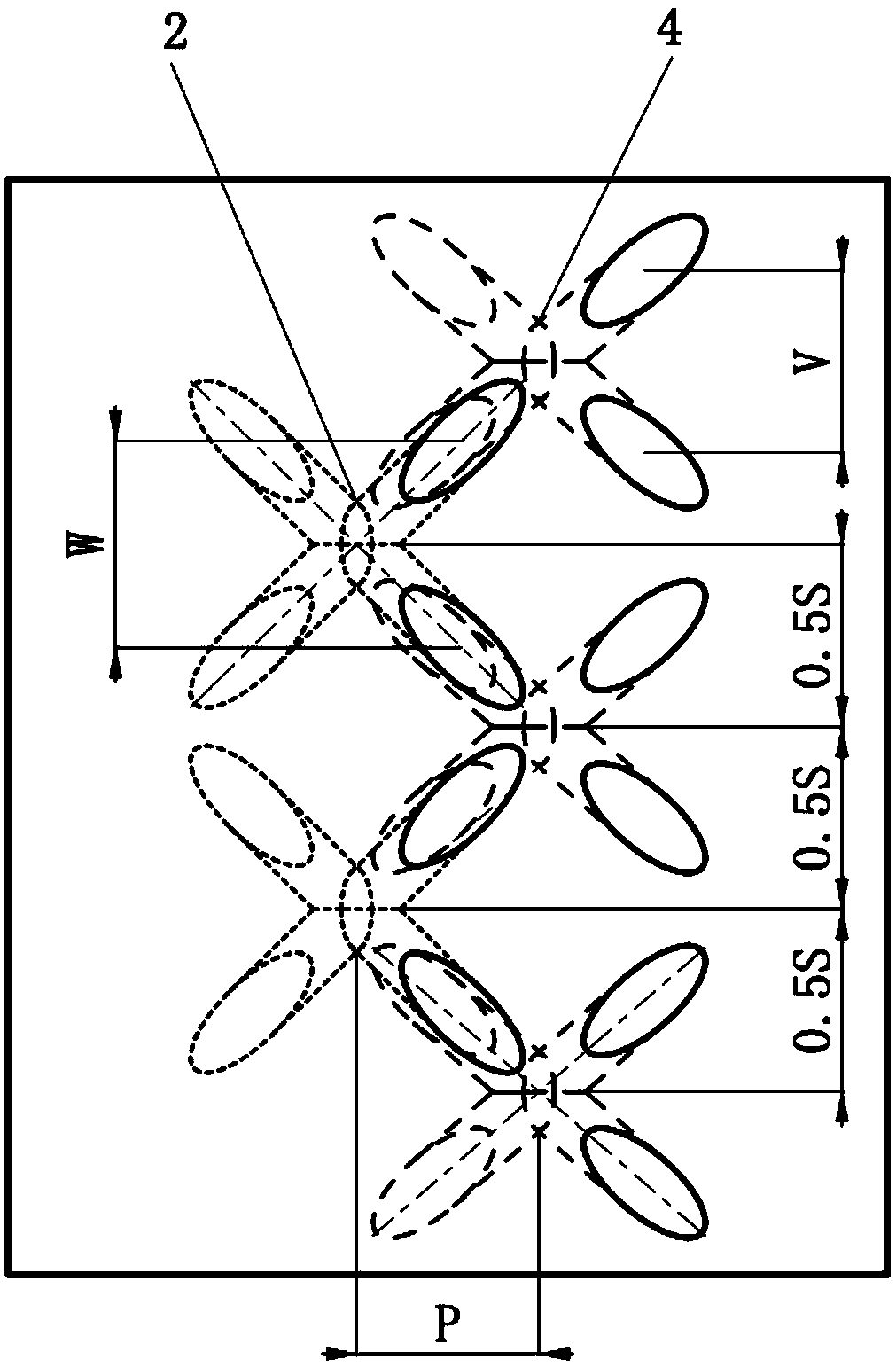

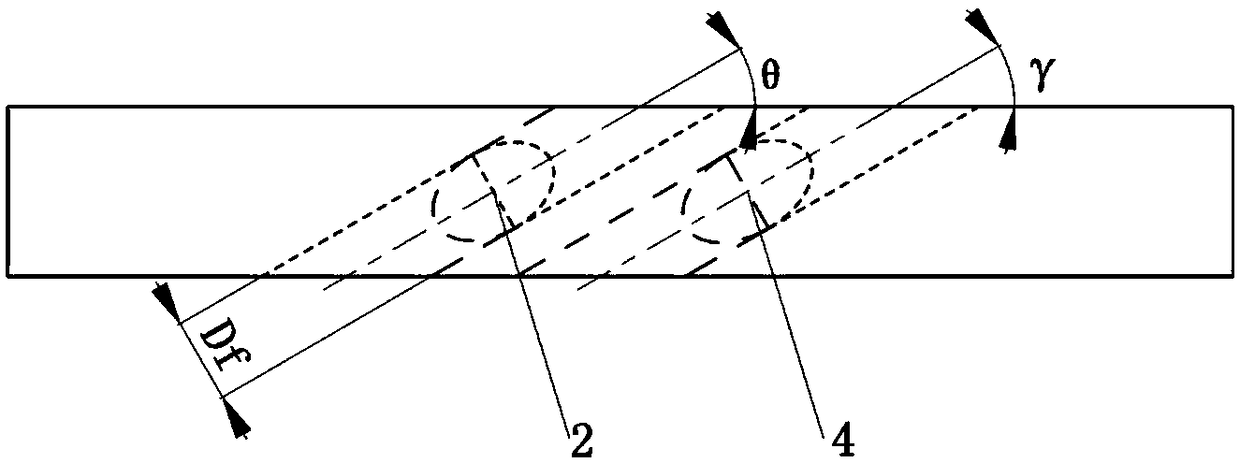

[0031] In this embodiment, the pressure surface cross-type X air film hole 7 and the pressure surface cross-type X air film hole 10 are arranged on the pressure surface of the turbine blade, and the air is supplied by the internal cooling passage 6, and the suction surface cross-type air film hole is arranged on the suction surface of the turbine blade. The X air film hole 9 is supplied by the internal cooling channel 8, wherein the first cylindrical air film hole 3 and the second cylindrical air film hole 11 intersect to form the upstream X air film hole 2, the third cylindrical air film hole 5 and the second cylindrical air film hole The four cylindrical air film holes 12 intersect to form the downstream X air film holes 4, and the upstream X air film holes 2 and the downstream X air film holes 4 are combined to form a cross-shaped X air film hole cooling structure.

[0032] The minimum cross-sectional equivalent diameter D of the first cylindrical air film hole 3, the second...

Embodiment 2

[0035] In this embodiment, the pressure surface cross-type X air film hole 7 and the pressure surface cross-type X air film hole 10 are arranged on the pressure surface of the turbine blade, the air is supplied by the internal cooling passage 6, and the cross-type X air film hole is arranged on the suction surface of the turbine blade. The film hole 9 is supplied by the internal cooling channel 8, wherein the first cylindrical air film hole 3 and the second cylindrical air film hole 11 intersect to form the upstream X air film hole 2, the third cylindrical air film hole 5 and the fourth cylinder The air film holes 12 intersect to form the downstream X air film holes 4, and the upstream X air film holes 2 and the downstream X air film holes 4 are combined to form a cross-shaped X air film hole cooling structure.

[0036] The minimum cross-sectional equivalent diameter D of the first cylindrical air film hole 3, the second cylindrical air film hole 11, the third cylindrical air f...

Embodiment 3

[0039] In this embodiment, the pressure surface cross-type X air film hole 7 and the pressure surface cross-type X air film hole 10 are arranged on the pressure surface of the turbine blade, the air is supplied by the internal cooling passage 6, and the cross-type X air film hole is arranged on the suction surface of the turbine blade. The film hole 9 is supplied by the internal cooling channel 8, wherein the first cylindrical air film hole 3 and the second cylindrical air film hole 11 intersect to form the upstream X air film hole 2; the third cylindrical air film hole 5 and the fourth cylindrical air film hole The air film holes 12 intersect to form the downstream X air film holes 4, and the upstream X air film holes 2 and the downstream X air film holes 4 are combined to form a cross-shaped X air film hole cooling structure.

[0040] The minimum cross-sectional equivalent diameter D of the first cylindrical air film hole 3, the second cylindrical air film hole 11, the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com