Water injection device with at least two tanks

A technology of water jetting equipment and water jetting, which is applied in the direction of adding non-fuel substances to mechanical equipment, machines/engines, fuel, etc., which can solve the problem of no installation space and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

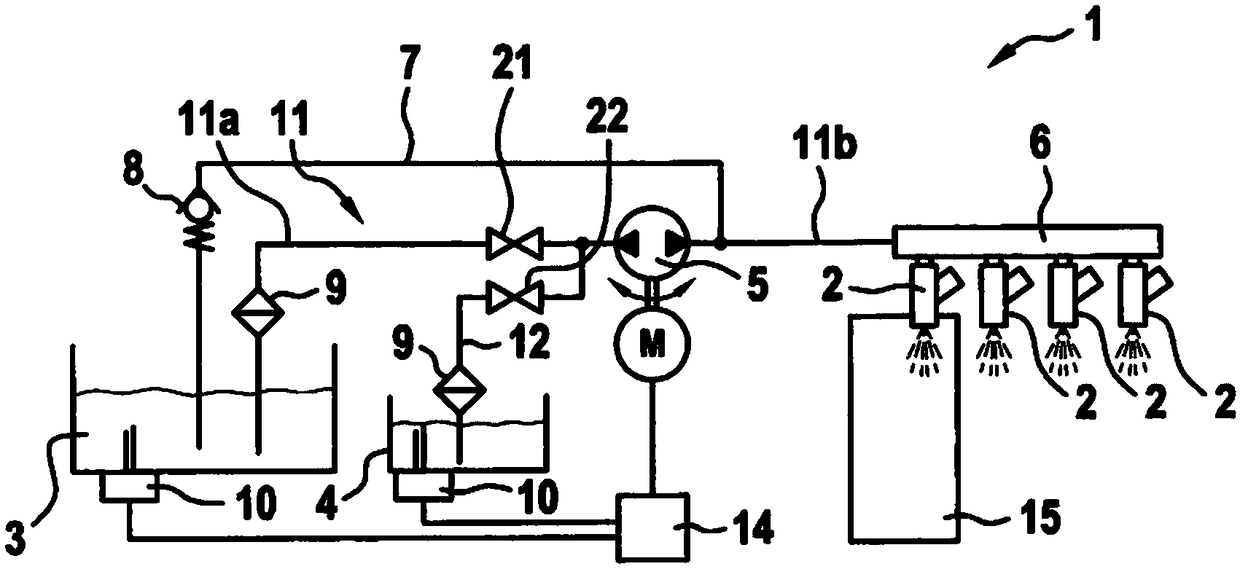

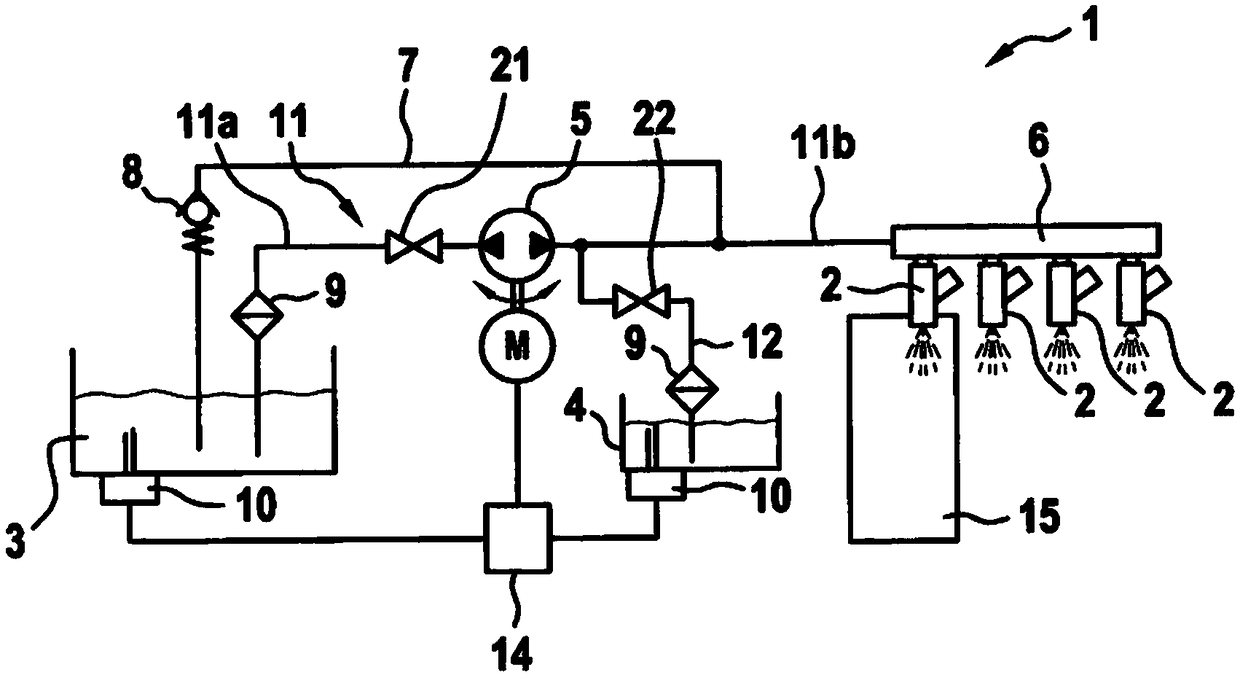

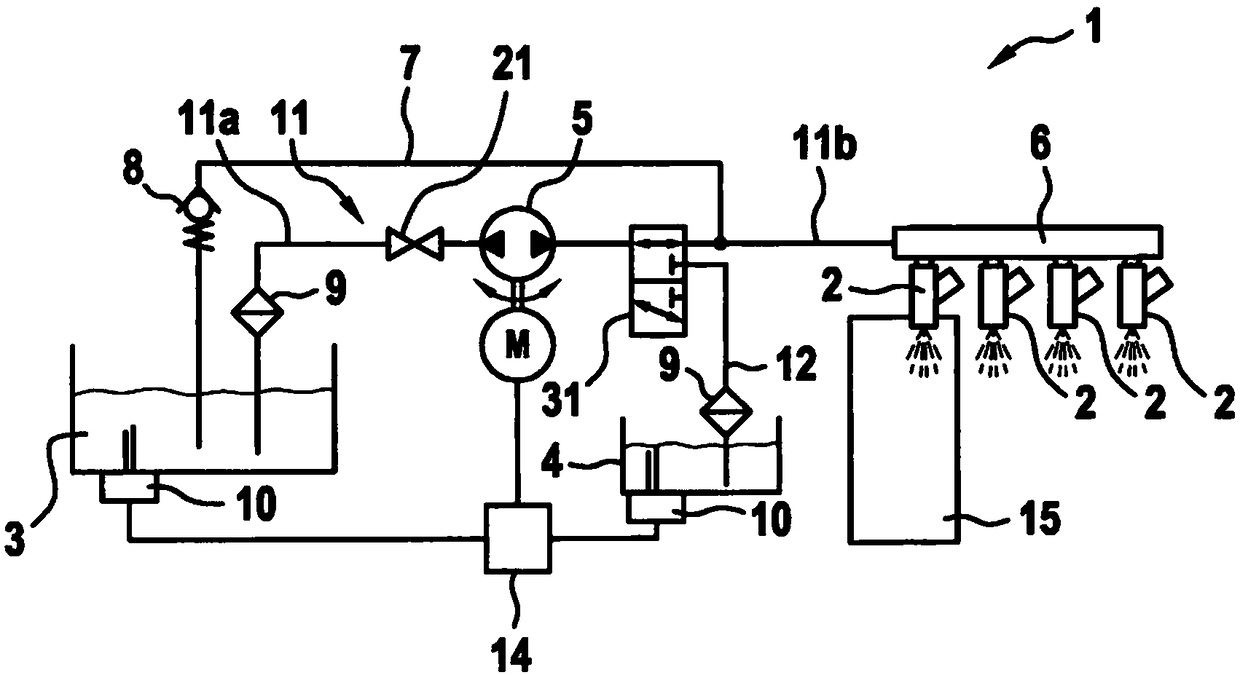

[0029] figure 1 A water jetting device 1 according to a first preferred embodiment of the invention is shown.

[0030] as from figure 1 As can be seen in the figure, the water spraying device 1 comprises a plurality of water sprayers 2 which are arranged on a water rail 6 . exist figure 1 Schematically shown in , water is injected directly into the combustion chamber 15 at the water injector 2 . However, it should be noted that it is also possible to inject water into the intake system of the internal combustion engine or both directly into the combustion chamber and into the intake system of the internal combustion engine.

[0031] Furthermore, the water spraying device 1 includes a first tank 3 and a second tank 4 for storing water. The first tank 3 is connected with the water rail 6 through the first water pipe 11 . The second tank 4 is connected with the first water pipe 11 through the second water pipe 12 .

[0032] Furthermore, a single double-acting pump 5 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com