Fan-in-fan workshop ceiling fan adopting double-row planetary gear train deceleration

A double-row planetary gear, fan-in-fan technology, applied in the field of electric fans, can solve the problems of high manufacturing cost, long fan blade length, difficult processing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

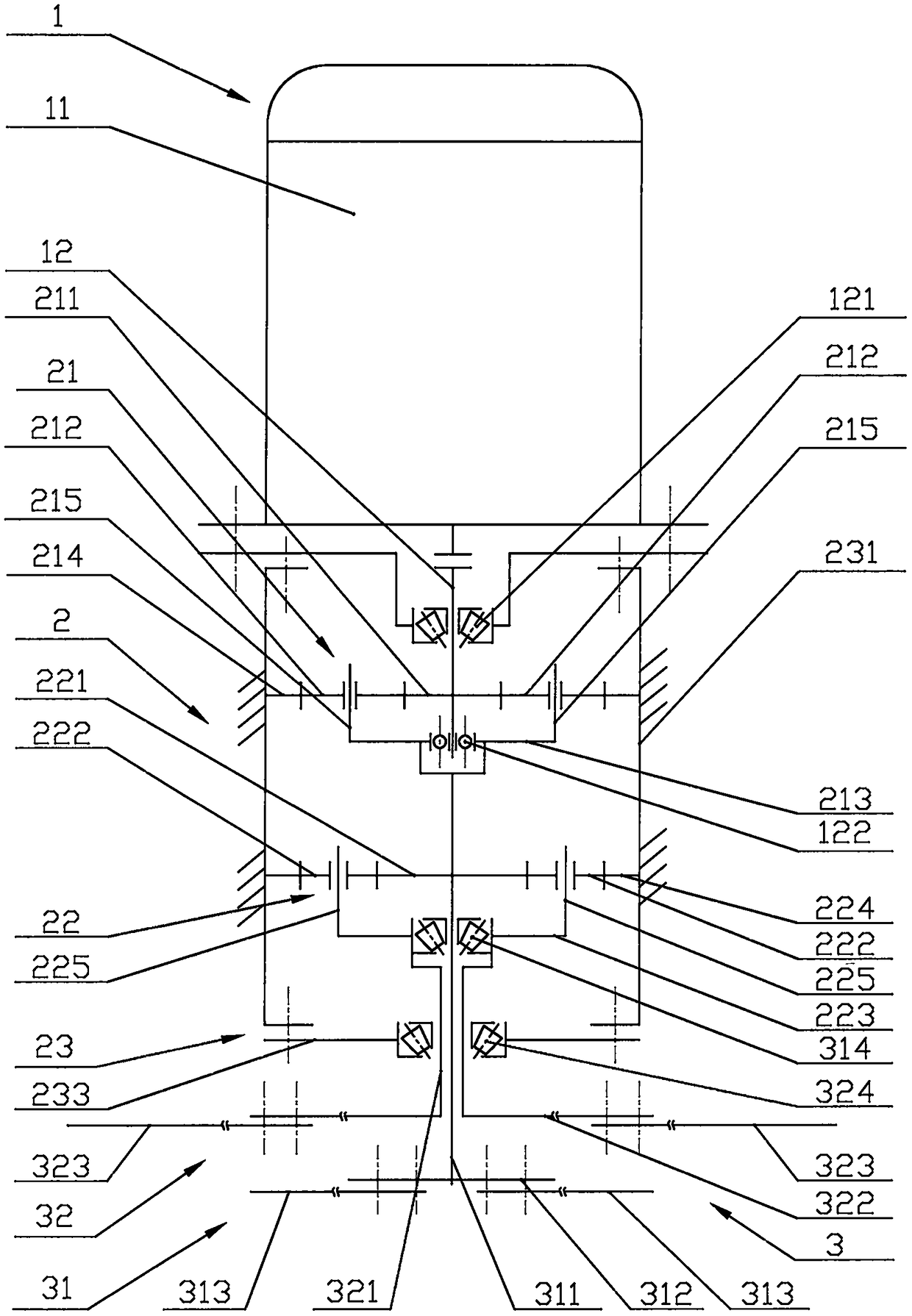

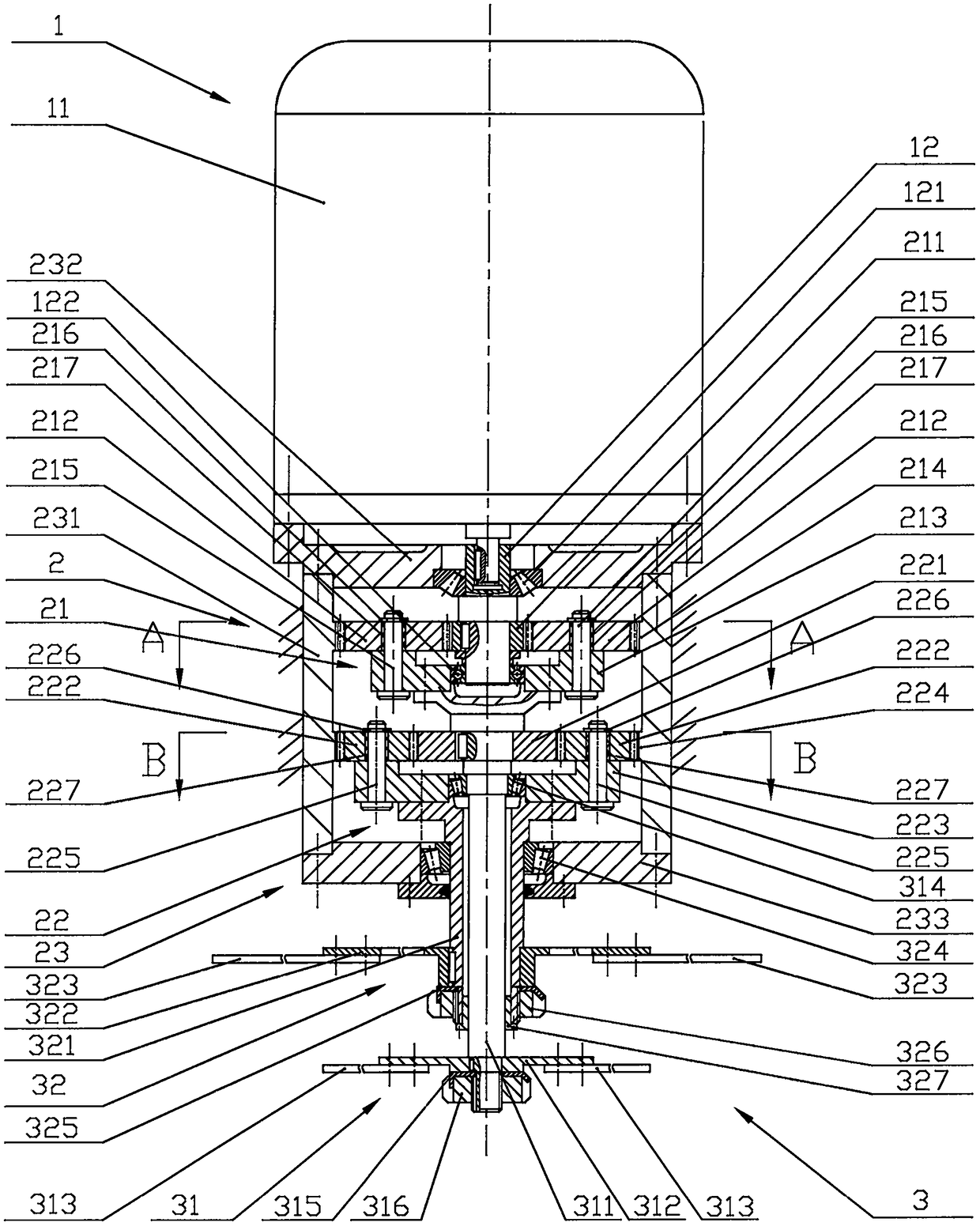

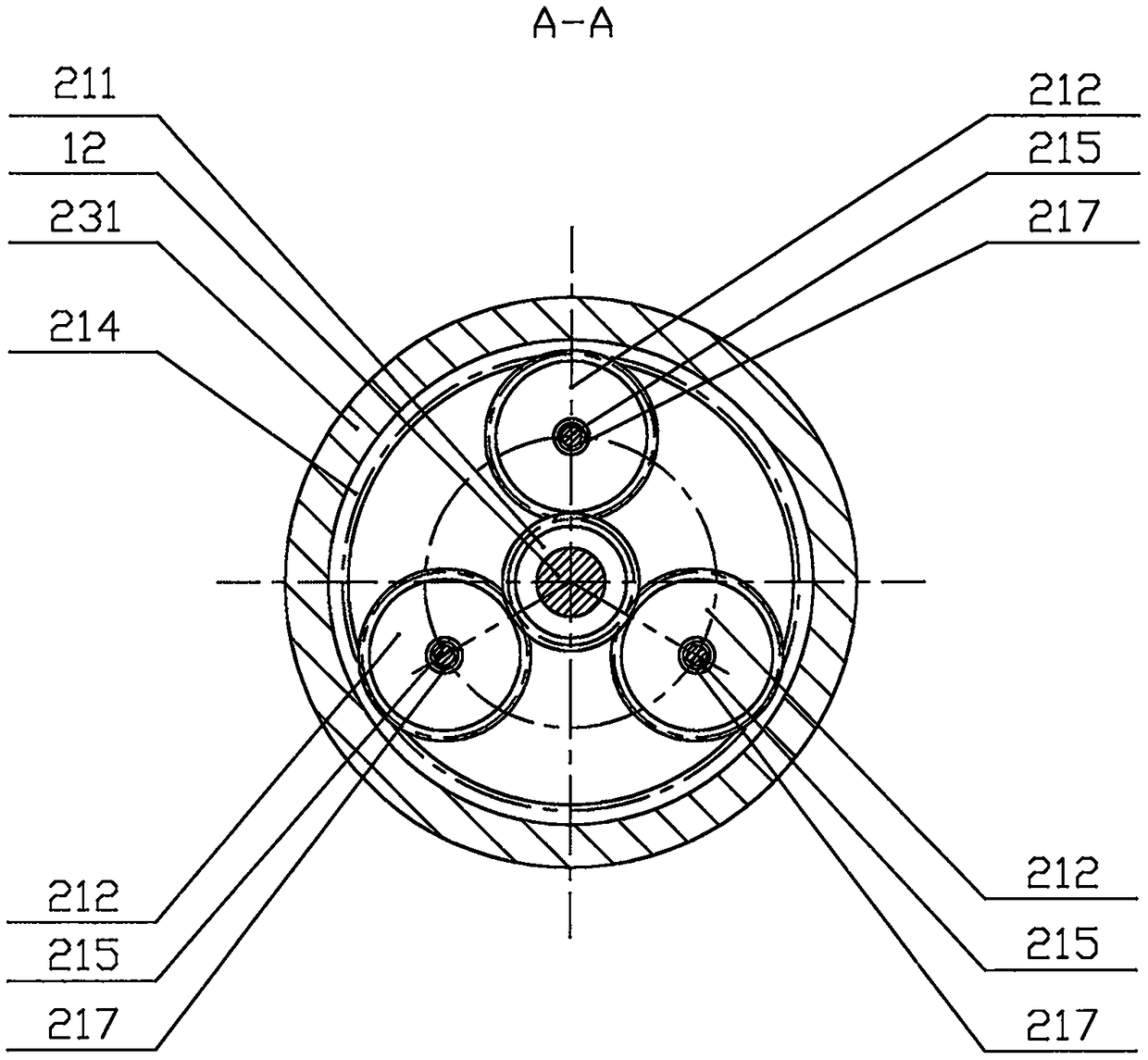

[0025] Such as figure 1 , 2, 3, 4, 5, and 6, the present invention provides a fan-in-fan workshop ceiling fan with double-row planetary gear train deceleration, and the present invention provides the following technical solutions: including drive mechanism 1, reducer 2 and fan main body 3. The drive mechanism 1 is set above the reducer 2, the fan main body 3 is set below the reducer 2, and the reducer 2 includes an upper planetary gear train 21 and a lower planetary gear train 22 and housing 23, the upper planetary gear train 21 includes an upper sun gear 211, an upper planetary gear 212, an upper planetary carrier 213 and an upper ring gear 214, and the upper ring gear 214 is fixed, and the The lower planetary gear train 22 includes a lower sun gear 221, a lower planetary gear 222, a lower planetary carrier 223 and a lower ring gear 224. The lower ring gear 224 is fixed, and the upper planetary carrier 213 is connected to the lower sun gear. The wheels 221 are coaxially con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com